Question

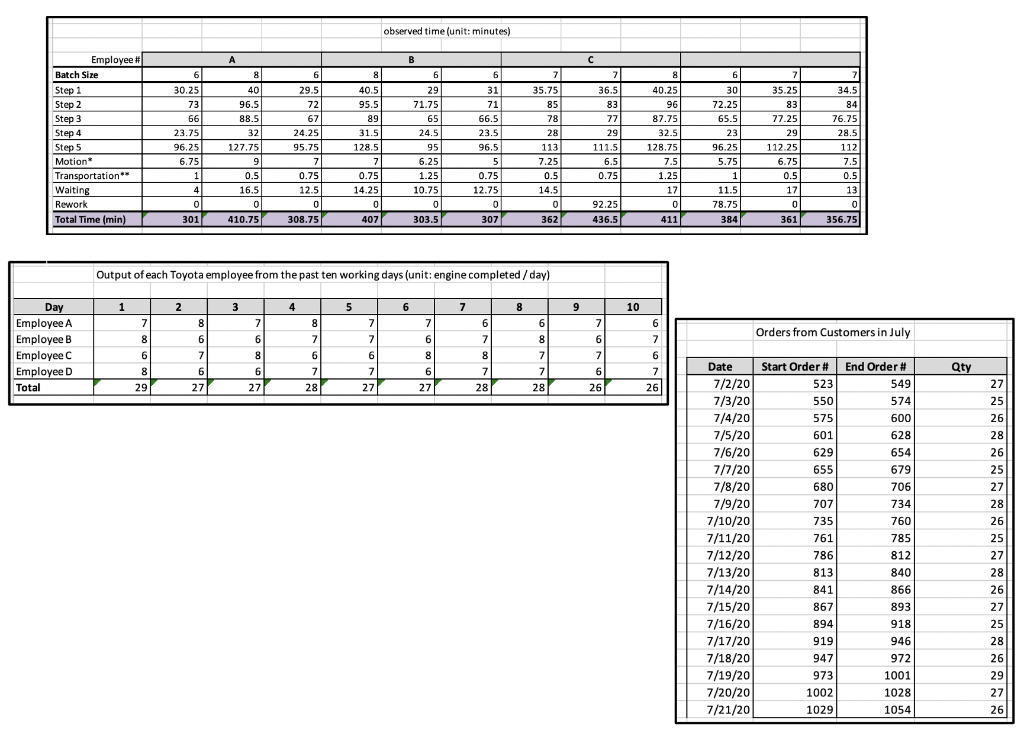

Toyota has a small division that makes engines every day. There is only one shift with 4 employees that makes this specific engine. During their

Toyota has a small division that makes engines every day. There is only one shift with 4 employees that makes this specific engine. During their 8-hour work shift, each employee produces engines in batches (about 6 or 8 engines per day) and the output varies depending on how much non-value time occurs. For three days straight, one observer recorded the minutes that each employee uses to complete their daily production. For ten days straight, another observer recorded the amount of output that each employee produced. A third observer was able to record the amount of units requested from the customer for the past month.

Use the three tables attached to find the following information for this small Toyota division:

Use the three tables attached to find the following information for this small Toyota division:

a) daily capacity

b) throughput time

c) operator utilization

observed time (unit: minutes) 8 8 40 96.5 88.5 32 B 6 29 71.75 65 Employee # Batch Size Step 1 Step 2 Step 3 Step 4 Step 5 Motion Transportation Waiting Rework Total Time (min) 7 35.25 83 77.25 29 24.5 6 30.25 73 66 23.75 96.25 6.75 1 4 0 301 6 29.5 72 67 24.25 95.75 7 0.75 12.5 0 8 8 40.5 95.5 89 31.5 128.5 7 0.75 14.25 0 407 7 36.5 83 77 29 111.5 6.5 0.75 6 31 71 66.5 23.5 96.5 5 0.75 12.75 0 0 307 40.25 96 87.75 32.5 128.75 7.5 1.25 127.75 9 9 0.5 16.5 0 410.75 7 35.75 85 78 28 113 7.25 0.5 14.5 0 0 362 95 6.25 1.25 10.75 0 303.5 112.25 6.75 0.5 6 301 72.25 65.5 23 96.25 5.75 1 11.5 78.75 384 7 34.5 84 76.75 28.5 112 7.5 0.5 13 0 356.75 17 92.25 436.5 0 411 17 0 0 361 308.75 Output of each Toyota employee from the past ten working days (unit: engine completed /day) / 1 2 3 4 5 6 7 8 9 10 7 6 7 8 6 8 6 7 7 6 8 8 7 6 6 7 Day Employee A Employee B Employee C Employee D Total 6 7 Orders from Customers in July 6 8 7 7 6 7 8 8 7 6 7 6 261 6 6 6 6 7 7 28 7 7 28 Qty 7 28 29 27 27 27 27 26 Start Order # 523 550 575 End Order # 549 574 600 628 654 601 629 655 680 707 Date 7/2/20 7/3/20 7/4/20 7/5/20 7/6/20 7/7/20 7/8/20 7/9/20 7/10/20 7/11/20 7/12/20 7/13/20 7/14/20 7/15/20 7/16/20 7/17/20 7/18/20 7/19/20 7/20/20 735 761 786 813 841 867 894 919 947 973 1002 1029 679 706 734 760 785 812 840 866 893 918 27 25 26 28 26 25 27 28 26 25 27 28 26 27 25 28 261 29 27 26 946 972 1001 1028 1054 7/21/20 observed time (unit: minutes) 8 8 40 96.5 88.5 32 B 6 29 71.75 65 Employee # Batch Size Step 1 Step 2 Step 3 Step 4 Step 5 Motion Transportation Waiting Rework Total Time (min) 7 35.25 83 77.25 29 24.5 6 30.25 73 66 23.75 96.25 6.75 1 4 0 301 6 29.5 72 67 24.25 95.75 7 0.75 12.5 0 8 8 40.5 95.5 89 31.5 128.5 7 0.75 14.25 0 407 7 36.5 83 77 29 111.5 6.5 0.75 6 31 71 66.5 23.5 96.5 5 0.75 12.75 0 0 307 40.25 96 87.75 32.5 128.75 7.5 1.25 127.75 9 9 0.5 16.5 0 410.75 7 35.75 85 78 28 113 7.25 0.5 14.5 0 0 362 95 6.25 1.25 10.75 0 303.5 112.25 6.75 0.5 6 301 72.25 65.5 23 96.25 5.75 1 11.5 78.75 384 7 34.5 84 76.75 28.5 112 7.5 0.5 13 0 356.75 17 92.25 436.5 0 411 17 0 0 361 308.75 Output of each Toyota employee from the past ten working days (unit: engine completed /day) / 1 2 3 4 5 6 7 8 9 10 7 6 7 8 6 8 6 7 7 6 8 8 7 6 6 7 Day Employee A Employee B Employee C Employee D Total 6 7 Orders from Customers in July 6 8 7 7 6 7 8 8 7 6 7 6 261 6 6 6 6 7 7 28 7 7 28 Qty 7 28 29 27 27 27 27 26 Start Order # 523 550 575 End Order # 549 574 600 628 654 601 629 655 680 707 Date 7/2/20 7/3/20 7/4/20 7/5/20 7/6/20 7/7/20 7/8/20 7/9/20 7/10/20 7/11/20 7/12/20 7/13/20 7/14/20 7/15/20 7/16/20 7/17/20 7/18/20 7/19/20 7/20/20 735 761 786 813 841 867 894 919 947 973 1002 1029 679 706 734 760 785 812 840 866 893 918 27 25 26 28 26 25 27 28 26 25 27 28 26 27 25 28 261 29 27 26 946 972 1001 1028 1054 7/21/20Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started