Question

Use the Location Problem Solution to generate TWO managerial questions to be answered using SolverTable. Your submission (including the spreadsheet) should include the following for

Use the Location Problem Solution to generate TWO managerial questions to be answered using SolverTable. Your submission (including the spreadsheet) should include the following for EACH managerial question:

1. The question to be answered (think about ALL possible reasons for your question/issue).

2. The SolverTable(s) used to generate data to answer the question (including any calculations).

3. The answer to the question including an explanation of your Solvertable(s).

Location Problem:

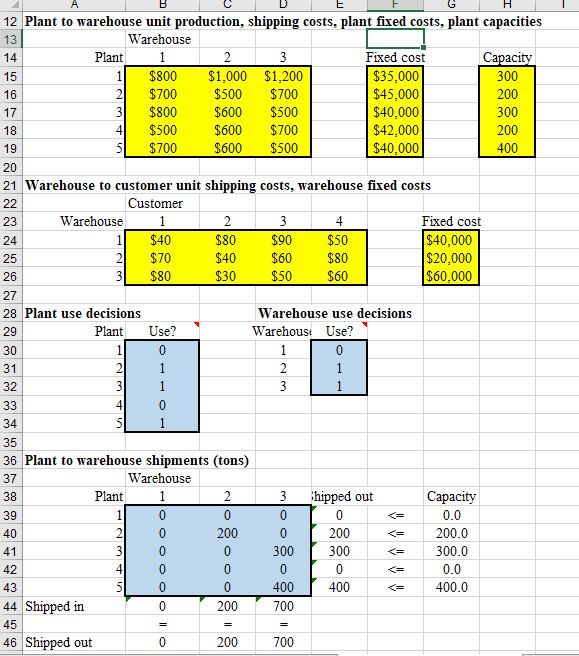

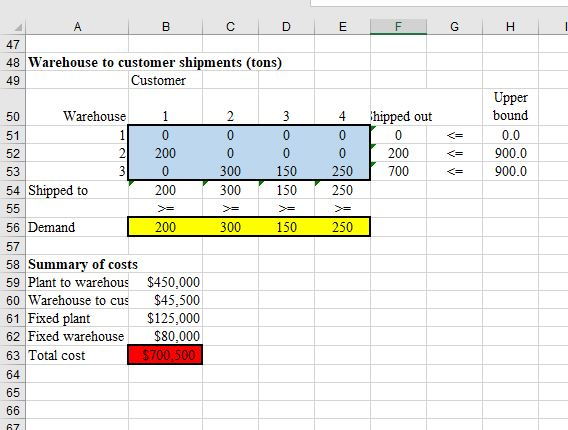

Huntco produces tomato sauce at five different plants. The capacity (in tons) of each plant is given below. The tomato sauce is stored at one of three warehouses. The cost per ton of producing tomato sauce at each plant and shipping it to each warehouse is given below. Huntco has four customers that must receive the amount of sauce they demand (in tons below). The cost of shipping a ton of sauce from each warehouse to each customer is given below. The annual fixed cost of operating each plant and warehouse is also given below. Huntco's goal is to minimize the annual cost of meeting customer demands. The company wants to detemine which plants and warehouses to open, as well as the optimal shipping plan.

15 1 19 1 12 Plant to warehouse unit production, shipping costs, plant fixed costs, plant capacities 13 Warehouse 14 Plant 2 3 Fixed cost Capacity $800 $1,000 $1,200 $35,000 300 16 21 $700 $500 $700 $45,000 200 17 3 $800 $600 $500 $40,000 300 18 4 $500 $600 $700 $42.000 200 $700 $600 $500 $40,000 400 20 21 Warehouse to customer unit shipping costs, warehouse fixed costs 22 Customer 23 Warehouse 2 3 4 Fixed cost 24 $40 $80 $90 $50 $40,000 25 $70 $40 $60 $80 $20,000 26 $80 $30 $50 $60 $60,000 27 28 Plant use decisions Warehouse use decisions 29 Plant Use? Warehous: Use? 30 0 0 31 2 2 32 3 3 33 34 35 36 Plant to warehouse shipments (tons) 37 Warehouse 38 Plant 2 3 hipped out Capacity 39 0 0 0.0 40 2 200 0 200.0 41 3 0 0 300 300 300.0 42 4 0 0 0 0 0.0 43 0 0 400 400 400.0 44 Shipped in 0 200 700 45 46 Shipped out 0 200 700 1 1 200 = 250 700 300 150 50 Warehouse 51 0 52 2 200 53 0 54 Shipped to 200 55 56 Demand 200 57 58 Summary of costs 59 Plant to warehous $450,000 60 Warehouse to cus $45,500 61 Fixed plant $125,000 62 Fixed warehouse $80,000 63 Total cost $700,500 64 65 66 67 15 1 19 1 12 Plant to warehouse unit production, shipping costs, plant fixed costs, plant capacities 13 Warehouse 14 Plant 2 3 Fixed cost Capacity $800 $1,000 $1,200 $35,000 300 16 21 $700 $500 $700 $45,000 200 17 3 $800 $600 $500 $40,000 300 18 4 $500 $600 $700 $42.000 200 $700 $600 $500 $40,000 400 20 21 Warehouse to customer unit shipping costs, warehouse fixed costs 22 Customer 23 Warehouse 2 3 4 Fixed cost 24 $40 $80 $90 $50 $40,000 25 $70 $40 $60 $80 $20,000 26 $80 $30 $50 $60 $60,000 27 28 Plant use decisions Warehouse use decisions 29 Plant Use? Warehous: Use? 30 0 0 31 2 2 32 3 3 33 34 35 36 Plant to warehouse shipments (tons) 37 Warehouse 38 Plant 2 3 hipped out Capacity 39 0 0 0.0 40 2 200 0 200.0 41 3 0 0 300 300 300.0 42 4 0 0 0 0 0.0 43 0 0 400 400 400.0 44 Shipped in 0 200 700 45 46 Shipped out 0 200 700 1 1 200 = 250 700 300 150 50 Warehouse 51 0 52 2 200 53 0 54 Shipped to 200 55 56 Demand 200 57 58 Summary of costs 59 Plant to warehous $450,000 60 Warehouse to cus $45,500 61 Fixed plant $125,000 62 Fixed warehouse $80,000 63 Total cost $700,500 64 65 66 67

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started