Question: Use the readings to help answer the questions on the last page. Thank you. CASE V Automotive Headlamps II: The Paradigm Shift from Standardized Glass

Use the readings to help answer the questions on the last page. Thank you.

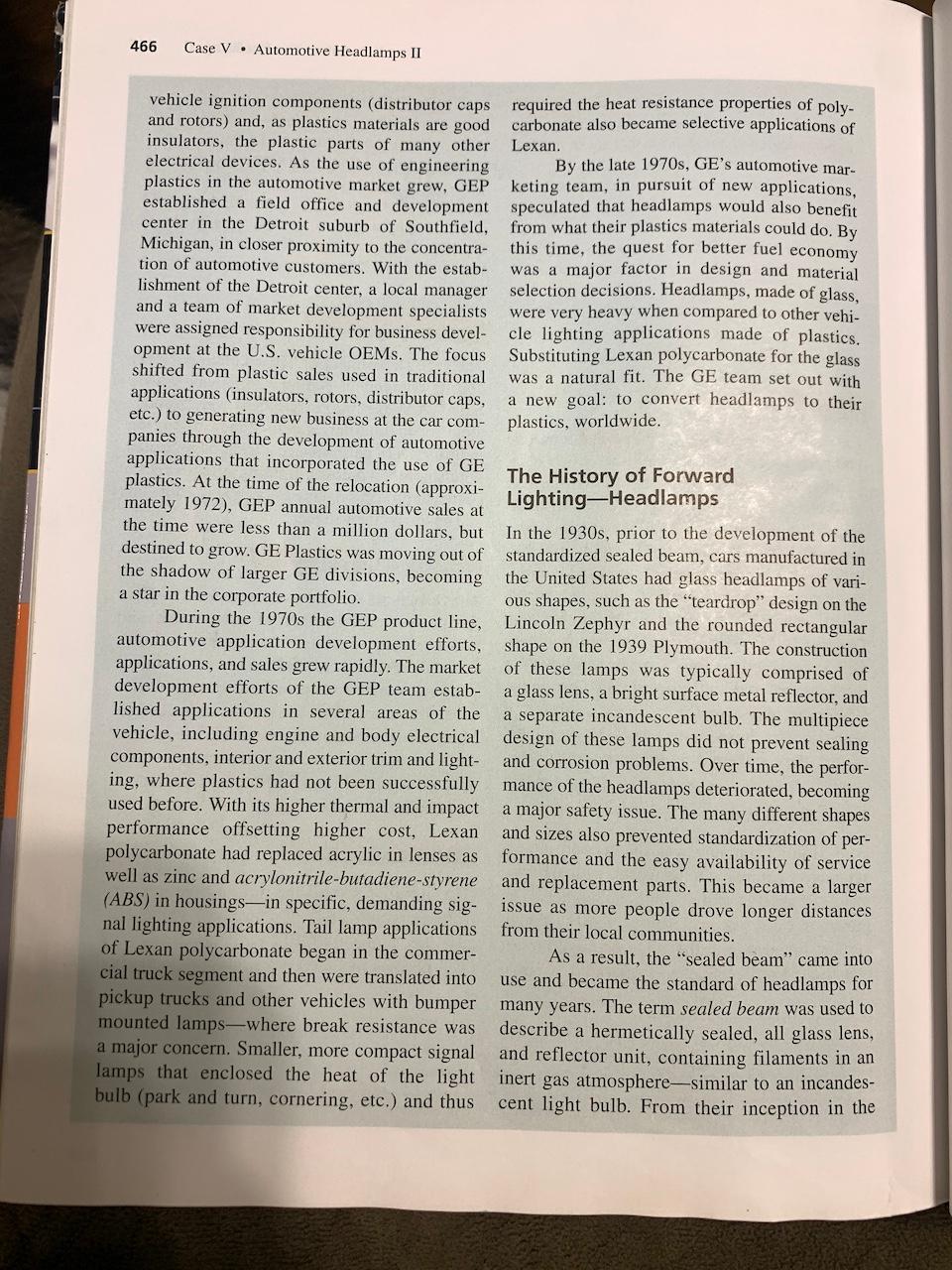

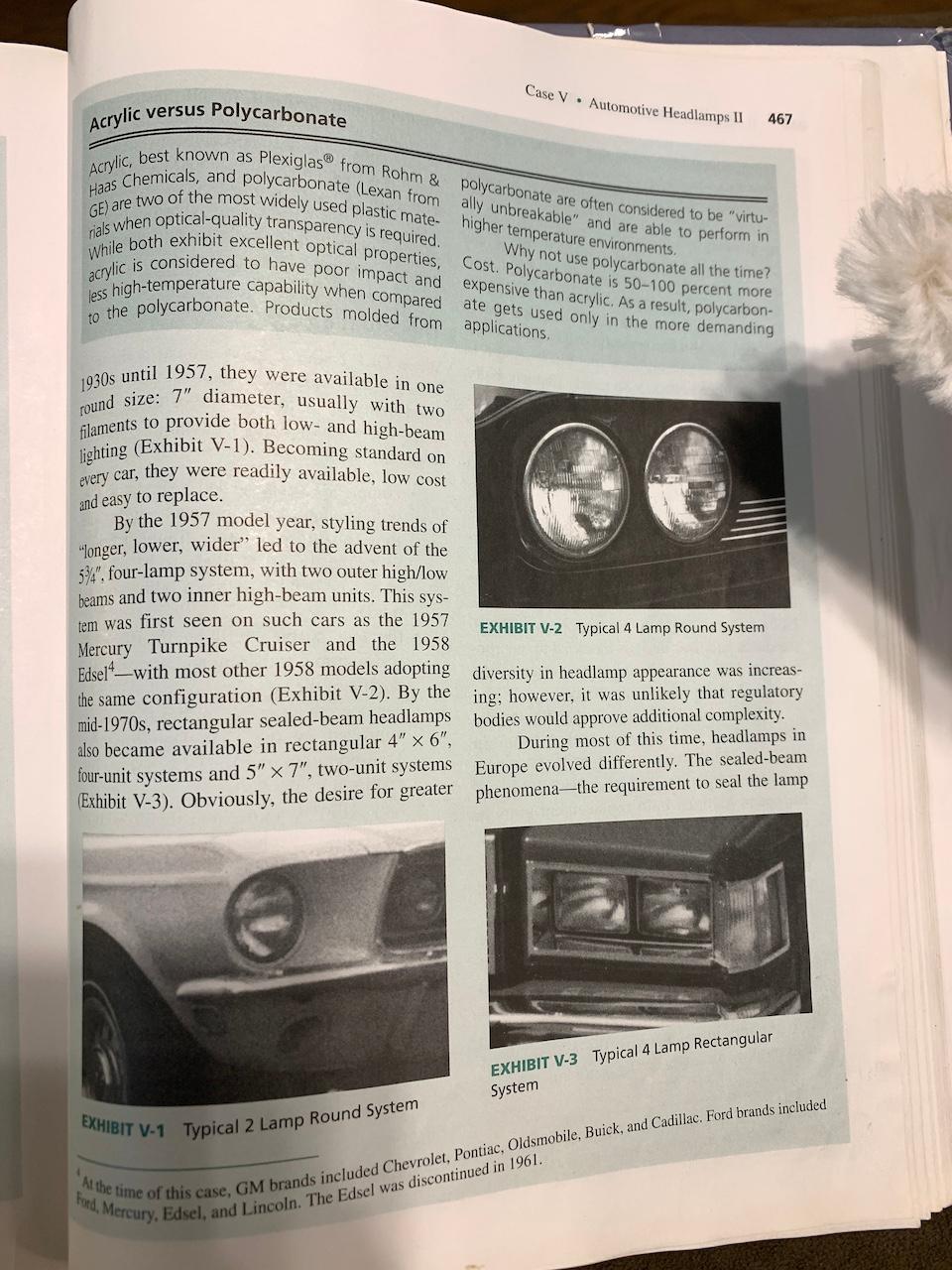

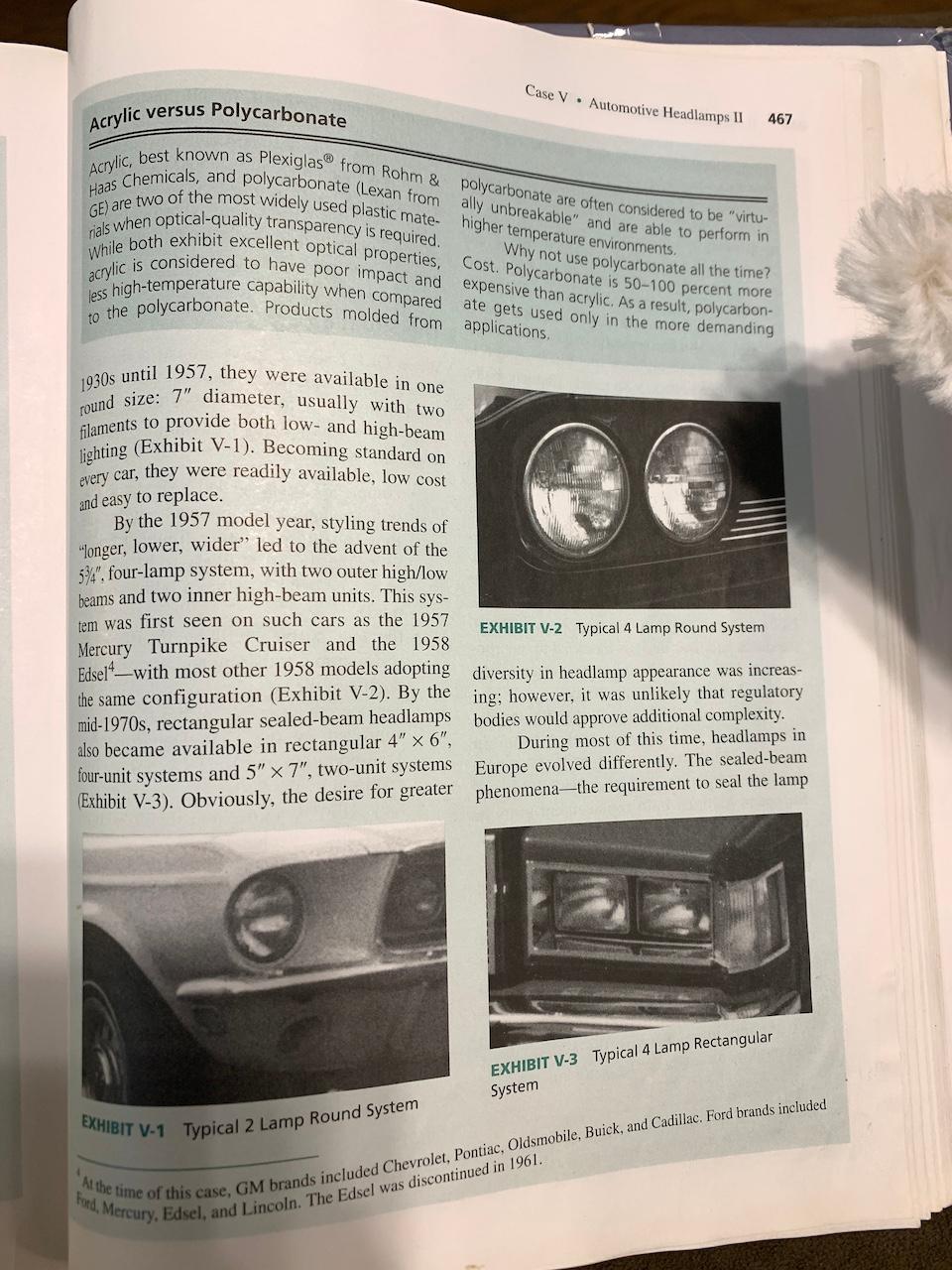

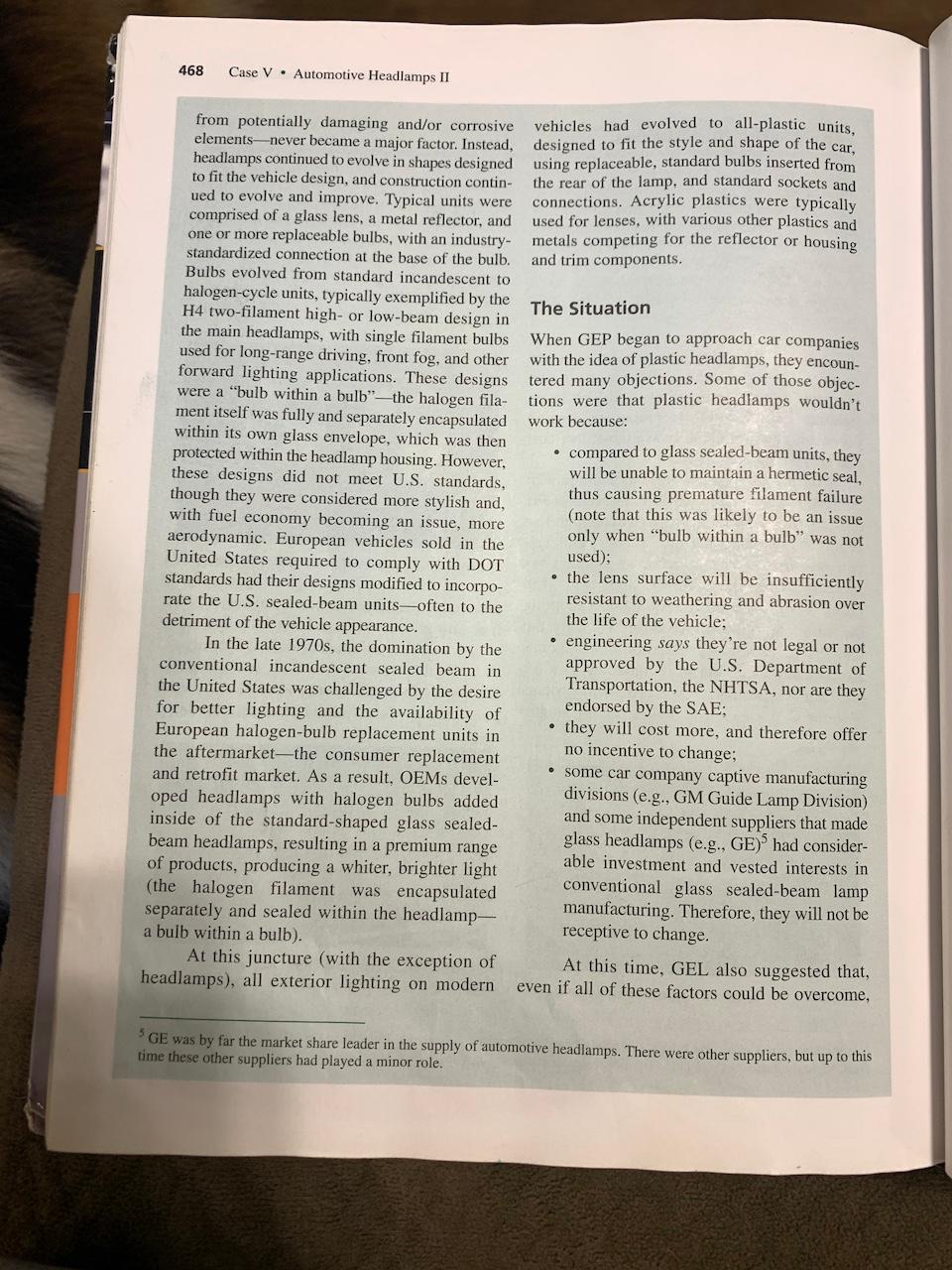

CASE V Automotive Headlamps II: The Paradigm Shift from Standardized Glass Sealed Beams to Today's Plastic Custom Designs Overview bases and radio cabinets) and, in 1930, formed the company's first plastics department to mar- This case brings together many factors: ket these plastic materials in the general market Strategic business unit management to other manufacturers of similar devices. philosophy Plastic materials with improved physical Innovation in the face of contrary "conven- properties were a continuously evolving need as tional wisdom" more complex component designs demanded How innovation can be viewed differently improved physical material properties. General by various stakeholders Electric Research and Development Laboratories, Customer organizational as well as product one of the premier industry-sponsored R&D goals centers, maintained an ongoing materials research Value, as perceived by the customer, rather effort. This led GE research labs to the develop- than the supplier. ment of new, thermoplastic engineering plas- tics such as polycarbonate (Lexan) in 1959, Introduction and Company polyphenylene oxide (PPO) in 1965, and PPO Backgrounds alloys (Noryl) by 1966. With these materials, GEP, then led by Jack Welch who was eventually For clarity, the backgrounds of the main players to become GE chairman, became a significant in this case are provided. factor in the growing plastics materials industry and a star in the GE corporate portfolio. General Electric The General Electric Lamp Division (GEL) The two strategic business units (SBU) of is an outgrowth of the very beginning of GE, dat- General Electric directly involved in this case ing back to the company's founding by Thomas are the General Electric Plastics Division and Edison in 1878. Over the years, GEL has been at the General Electric Lamp Division. the forefront of lighting developments in almost The General Electric Company Plastics every market: stadium lighting, aircraft and air- Division (GEP) began as an internal supplier of port lighting systems, home lighting, to name thermoset phenolic molding compounds used a few; and in every technology-incandescent in electrical components (such as vacuum tube (such as standard light bulbs), fluorescent, mercury Thermosets and Thermoplastics Simply defined, thermoset phenolics are those materials that undergo a chemical change when heat is applied in the molding process and, when reheated, do not melt. These materials are capable of withstanding high heats without de- forming but usually have poorer physical proper- ties than thermoplastics. Engineering thermoplastics are materials that can be melted again after the initial molding process, analogous to ice melting to water and then being cooled to ice again. Thermoplastics are easier to recycle and generally have better physical properties, making possible more complex part designs. 1 e 464 Case V Automotive Headlamps II lamp turing facilities.? Ford, like GM, manufactured many of its own components including lighting devices and was strongly vertically integrated in the manufacture of components made of remained of GEL. vapor, sodium, and others. GEL is an integrated, steel mills, rubber plantations, automotive glass 465 high-volume producer and is among the only plants (windows, windshields-not lighting), lighting device manufacturers that make most of iron ore barges and mines, and paint manufac- its own glass for its products. The glass sealed-beam automotive head- introduced in the 1930s, is one of the developments that GEL is most proud. At the time of this case, GEL was the largest supplier plastics. However, Ford did not manufacture of light bulbs" to the North American automo- headlamps and thus was the largest customer tive market. The sealed-beam design had an industry standard from the 1930s to the date of this case. Within the GE corporate Regulatory Agencies structure, GEL was a significant cash cow. The U.S. Department of Transportation (DOT) General Motors and its component National Highway Traffic Safety Administration (NHTSA) were respon- General Motors (GM), the largest automotive sible for maintaining safety standards for the company in the world, at the time of this case, industry. DOT performance standards regulated held almost 60 percent of the American windshields, windows, lighting effectiveness, market. GM was built primarily through occupant protection devices (airbags, seatbelts), acquisition of not only smaller car companies and so on, on the vehicles. but supplier companies and brands as well. Professional Organizations AC Spark Plugs and Delco electrical compo- nents were among GM-owned, through acqui- The Society of Automotive Engineers (SAE) is sition, supply divisions. The GM Guide Lamp the professional society of automotive and Division (GMGuide not to be confused with transportation engineers. As the auto industry GEL) produced various lamp assemblies for evolved, the SAE, as with many professional the interior and exterior of GM products. societies, created voluntary performance stan- GMGuide was also the primary supplier of dards for many vehicle systems and devices. sealed-beam headlamps to GM vehicles, Many SAE-recommended performance stan- dards became standard industry practice. DOT though they were not as integrated as GEL 1 adapted many of these voluntary standards as regulations. Ford Motor Company automotive GEP Organization GEP initially served the automotive industry from a district office in Cleveland, coinciden- GEP plastics included use in the production of Ford Motor Company was the second largest company in the world, with approxi- mately 25 percent of the American market. - The growth of Ford was achieved primarily through one time, Ford owned and operated its own Vertical integration rather than acquisition. At tally the "home" of GEL. Early applications of engaged in the supply of automotive components to the automotive industry. At this writing, many GM captive supply divisions have been spun off into Delphi Corporation, a separate company At this writing, Toyota has passed Ford in number of worldwide vehicle sales. ngaged in the supply of automotive components to the automotive industry. As with GM, many Ford captive supply divisions have been spun off into Visteon Corporation, a separate company 466 Case V Automotive Headlamps II vehicle ignition components (distributor caps required the heat resistance properties of poly- and rotors) and, as plastics materials are good carbonate also became selective applications of insulators, the plastic parts of many other Lexan. electrical devices. As the use of engineering By the late 1970s, GE's automotive mar- plastics in the automotive market grew, GEP keting team, in pursuit of new applications, established a field office and development speculated that headlamps would also benefit center in the Detroit suburb of Southfield, from what their plastics materials could do. By Michigan, in closer proximity to the concentra- this time, the quest for better fuel economy tion of automotive customers. With the estab- was a major factor in design and material lishment of the Detroit center, a local manager selection decisions. Headlamps, made of glass, and a team of market development specialists were very heavy when compared to other vehi- were assigned responsibility for business devel- cle lighting applications made of plastics. opment at the U.S. vehicle OEMs. The focus Substituting Lexan polycarbonate for the glass shifted from plastic sales used in traditional was a natural fit. The GE team set out with applications (insulators, rotors, distributor caps, a new goal: to convert headlamps to their etc.) to generating new business at the car com- plastics, worldwide. panies through the development of automotive applications that incorporated the use of GE plastics. At the time of the relocation (approxi- The History of Forward mately 1972), GEP annual automotive sales at Lighting-Headlamps the time were less than a million dollars, but In the 1930s, prior to the development of the destined to grow. GE Plastics was moving out of standardized sealed beam, cars manufactured in the shadow of larger GE divisions, becoming the United States had glass headlamps of vari- a star in the corporate portfolio. ous shapes, such as the "teardrop" design on the During the 1970s the GEP product line, Lincoln Zephyr and the rounded rectangular automotive application development efforts, shape on the 1939 Plymouth. The construction applications, and sales grew rapidly. The market of these lamps was typically comprised of development efforts of the GEP team estab- a glass lens, a bright surface metal reflector, and lished applications in several areas of the a separate incandescent bulb. The multipiece vehicle, including engine and body electrical design of these lamps did not prevent sealing components, interior and exterior trim and light- and corrosion problems. Over time, the perfor- ing, where plastics had not been successfully mance of the headlamps deteriorated, becoming used before. With its higher thermal and impact a major safety issue. The many different shapes performance offsetting higher cost, Lexan and sizes also prevented standardization of per- polycarbonate had replaced acrylic in lenses as formance and the easy availability of service well as zinc and acrylonitrile-butadiene-styrene and replacement parts. This became a larger (ABS) in housingsin specific, demanding sig- issue as more people drove longer distances nal lighting applications. Tail lamp applications from their local communities. of Lexan polycarbonate began in the commer- As a result, the "sealed beam" came into cial truck segment and then were translated into use and became the standard of headlamps for pickup trucks and other vehicles with bumper many years. The term sealed beam was used to mounted lamps-where break resistance was describe a hermetically sealed, all glass lens, a major concern. Smaller, more compact signal and reflector unit, containing filaments in an lamps that enclosed the heat of the light inert gas atmosphere-similar to an incandes- bulb (park and turn, cornering, etc.) and thus cent light bulb. From their inception in the Case V. Automotive Headlamps 11 467 Acrylic versus Polycarbonate polycarbonate are often considered to be "virtu- Acrylic, best known as Plexiglas from Rohm & Haas Chemicals, and polycarbonate (Lexan from ally unbreakable" and are able to perform in GE) are two of the most widely used plastic mate higher temperature environments. While both exhibit excellent optical properties, rials when optical-quality transparency is required. acrylic is considered to have poor impact and less high-temperature capability when compared to the polycarbonate. Products molded from applications Why not use polycarbonate all the time? Cost. Polycarbonate is 50-100 percent more expensive than acrylic. As a result, polycarbon- ate gets used only in the more demanding and easy to replace. 1930s until 1957, they were available in one round size: 7" diameter, usually with two filaments to provide both low- and high-beam lighting (Exhibit V-1). Becoming standard on every car, they were readily available, low cost By the 1957 model year, styling trends of "longer, lower, wider led to the advent of the 5", four-lamp system, with two outer high/low beams and two inner high-beam units. This sys- tem was first seen on such cars as the 1957 EXHIBIT V-2 Typical 4 Lamp Round System Mercury Turnpike Cruiser and the 1958 Edsel4-with most other 1958 models adopting diversity in headlamp appearance was increas- the same configuration (Exhibit V-2). By the ing; however, it was unlikely that regulatory mid-1970s, rectangular sealed-beam headlamps bodies would approve additional complexity. also became available in rectangular 4" x 6", During most of this time, headlamps in four-unit systems and 5" x 7", two-unit systems Europe evolved differently. The sealed-beam (Exhibit V-3). Obviously, the desire for greater phenomenathe requirement to seal the lamp EXHIBIT V-3 Typical 4 Lamp Rectangular System EXHIBIT V-1 Typical 2 Lamp Round System Ford, Mercury, Edsel, and Lincoln. The Edsel was discontinued in 1961. the time of this case, GM brands included Chevrolet, Pontiac, Oldsmobile, Buick, and Cadillac. Ford brands included 468 Case V Automotive Headlamps II from potentially damaging and/or corrosive vehicles had evolved to all-plastic units, elements never became a major factor. Instead, designed to fit the style and shape of the car, headlamps continued to evolve in shapes designed using replaceable, standard bulbs inserted from to fit the vehicle design, and construction contin- the rear of the lamp, and standard sockets and ued to evolve and improve. Typical units were connections. Acrylic plastics were typically comprised of a glass lens, a metal reflector, and used for lenses, with various other plastics and one or more replaceable bulbs, with an industry- metals competing for the reflector or housing standardized connection at the base of the bulb. and trim components. Bulbs evolved from standard incandescent to halogen-cycle units, typically exemplified by the H4 two-filament high- or low-beam design in The Situation the main headlamps, with single filament bulbs When GEP began to approach car companies used for long-range driving, front fog, and other with the idea of plastic headlamps, they encoun- forward lighting applications. These designs tered many objections. Some of those objec- were a "bulb within a bulb"-the halogen fila- tions were that plastic headlamps wouldn't ment itself was fully and separately encapsulated work because: within its own glass envelope, which was then protected within the headlamp housing. However, compared to glass sealed-beam units, they these designs did not meet U.S. standards, will be unable to maintain a hermetic seal, though they were considered more stylish and, thus causing premature filament failure with fuel economy becoming an issue, more (note that this was likely to be an issue aerodynamic. European vehicles sold in the only when "bulb within a bulb" was not United States required to comply with DOT used); standards had their designs modified to incorpo- the lens surface will be insufficiently rate the U.S. sealed-beam units often to the resistant to weathering and abrasion over detriment of the vehicle appearance. the life of the vehicle; In the late 1970s, the domination by the engineering says they're not legal or not conventional incandescent sealed beam in approved by the U.S. Department of the United States was challenged by the desire Transportation, the NHTSA, nor are they endorsed by the SAE; for better lighting and the availability of they will cost more, and therefore offer European halogen-bulb replacement units in no incentive to change; the aftermarket-the consumer replacement and retrofit market. As a result, OEMs devel- some car company captive manufacturing divisions (e.g., GM Guide Lamp Division) oped headlamps with halogen bulbs added inside of the standard-shaped glass sealed- and some independent suppliers that made beam headlamps, resulting in a premium range glass headlamps (e.g., GE) had consider- able investment and vested interests in of products, producing a whiter, brighter light (the halogen filament was encapsulated conventional glass sealed-beam lamp separately and sealed within the headlamp- manufacturing. Therefore, they will not be a bulb within a bulb). receptive to change. At this juncture (with the exception of At this time, GEL also suggested that, headlamps), all exterior lighting on modern even if all of these factors could be overcome, GE was by far the market share leader in the supply of automotive headlamps. There were other suppliers, but up to this time these other suppliers had played a minor role. Case V Automotive Headlamps II 469 Captive and Custom Molders A manufacturer that makes plastics components itself at its own plastic manufacturing facilities is facilities that produce plastic parts strictly for said to have "captive facilities"-manufacturing that manufacturer. When outsourced, plastic components are produced to the manufacturer's specifications by custom injection molders- contract providers that produce plastic parts as designed and specified by the manufacturer Faced with these objections, a few mem- the styled headlamp was a fad, that wouldn't be universally adopted by the industry. The Lexan lamp would be significantly lighter than a glass sealed-beam lamp bers of the GEP marketing team felt that the contributing to need for lower vehicle project was not worth pursuing. The time spent weight. marketing the plastic headlamp could be better These benefits, when combined into spent on less complex applications (really meaning applications with easier to overcome a package, could provide a method for manu- facturers to make their cars look better and and fewer objections). Still, the GEP Detroit different and have that advantage over their team wanted to move forward and develop competitors, potentially reduce collision haz- business in plastic headlamps, and a few people ards, and contribute to the overall goal to were prepared to bet their careers on it. produce lighter vehicles. Indeed, at this time there was a heightened concern for safety, since a spate of sensational rear-end collisions and The Marketing Plan resultant fires had occurred coincidentally. In Benefits addition to the safety aspects, GEP noted the GEP marketing people began analyzing and proposed shaped-to-the-car flush designs as developing ideas about the benefits of plastic being more aerodynamic, and thus contributing to less drag and better fuel economy. (The new headlamps to OEM's. They concluded that the concept was quickly tagged as the aerodynamic primary benefits of plastics were headlamp at Ford, and the term was used the ability to create unique designs with during development and application.) easier optical detail reproduction than Risks glass, allowing vehicle manufacturers to design a more modern, smooth, stream- lined front end, with the headlamps inte- The development project was not without grated into the overall vehicle shape and risks, both for customers and the GEP team. mounted flush to adjacent surfaces. GMGuide (now part of Delphi Automotive) was the plastic and halogen bulb combination the primary supplier of glass sealed-beam head- could reduce the risk of fire in a rear-end lamps to GM. GMGuide was unreceptive, and collision since the Lexan was virtually its general manager typified this by stating unbreakable and even if broken, the bulb emphatically that the company was not going to filament was separately encapsulated. change from glass to plastic because sand (the cheaper than oil (the raw material in plastic)." compared to the glass sealed-beam unit, with its incandescent filament exposed The GEP program manager also recalls being practically thrown out of a meeting by the head Therefore the risk of fire was reduced, basic raw material in glass) will always be when broken 470 Case V Automotive Headlamps II a A ga he ill OL bo al se co na er company to innovate. ul m th gl fi br va of GEL at GEL home offices near Cleveland. on the vehicle. If headlamps were to be made of Fortunately, GEP's management at the plastic, Ford could manufacture the housings Pittsfield, MA, headquarters backed the efforts itself, purchasing just the filament (bulb within of the GEP Detroit team and provided political a bulb) from outside sources. Additionally, support within GE for them. Ford was known as more receptive to innova- tive ideas, particularly from a marketing Finding the Right Customer perspective as it understood the role innovation The GEP approach to the customer then played in a better product and image in the changed. Realizing that the potential customers market. These factors combined to lead the within the customer were actually those who GEP team to focus on Ford as the most likely would value the benefits of styling differentia- tion, they focused on the design and styling The GEP team developed a champion organization of the car companies, as well as within the Ford organization: an open-minded, managers in product planning and marketing. In creative manager in advanced engineering- other words, attention centered on the people at who not only "got it," but wanted to see it the car companies who were responsible for the happen himself. Though the effort was consid- way a car looked and sold. The degree to which ered to be a waste of time by some Ford person- these stakeholders (marketing, styling/design, nel, particularly in regard to the previously and product planning departments) within the mentioned regulatory risks, the Ford "intrapre- car company buying centers could influence neur" and the GEP team began a program to the other members (engineering and purchasing make the new lamp happen. people) became critical. While engineering Challenging the Standard was a necessary, if sometimes reluctant ally, they did not determine vehicle content. After GEP marketing people started to politely but approaching all major car manufacturers, the systematically question "legal" assumptions. GEP marketing team realized that GM was not They made some important discoveries. Most a likely first customer because GMGuide was everyone had assumed the incumbent designs to focused on cost, not innovation. Though some be necessary (sealed, one-piece glass). However, GM designers, particularly at Cadillac, had Sylvania, a small lamp producer, was to shortly expressed interest in the plastic aerodynamic prove that this was not the case. The applicable headlamp, they would not be able to take advan- SAE standard was in place primarily as a design tage of the development until GMGuide was guideline to describe the significant dimensions, ready to embrace the technology. The situation mounting and aiming points, and so on of was different at Ford. sealed-beam headlampsbut not outlining or Ford did not manufacture its own glass determining performance. headlamps, instead was purchasing most of its GEP also decided to question the "legal" needs from GEL. Ford was, however, fully assumptions at the external agency level. The integrated in the manufacturing of plastic GEP program manager contacted a senior DOT components, among those all of the other lamps official in Washington, D.C., and arranged G he th tir thi the wl GI ag ne ha tes wi ag CO 6 ma hea ve Sylvania, a small competitor to GEL but looking for a bigger presence in automotive lighting, was attempting to enter the market with glass sealed" beam halogen headlamps that were made of a separate lens and housing. The two separate parts were bonded and the hermetic seal was achieved with adhesive rather than the industry-standard "flame sealing" that melted the two pieces of glass together. If the adhesive system worked, Sylvania could avoid the investment in the flame-sealing process. GEL believed that, ultimately, this adhesive design would not survive neither the DOT approval process nor vehicle durability requirements. ver bea bu mo Case V Automotive Headlamps 11 coating, bonded to an injection molded, metal- f s 1 471 a meeting to discuss a new, safe headlamp idea. At this meeting, the official indicated that the lized, and coated reflector/housing. The vehicle government's only real concern was that application was the inboard lamp of the four- illumination over the period of its life (or that headlights provided the driver consistent, safe lamp rectangular system (high beam only, as be widely available. In fact, they did not care of the car) and, should one fail, replacements units on the 1980 Lincoln Town Car, of which about their material or shape. The GEP repre- sentative cited the safety benefits of the plastic beam units were used on the outer high/low concept. The plastic and halogen bulb combi- nation would reduce the risk of fire in a rear- end collision-since the Lexan was virtually experience and prove the durability of the unbreakable and even if broken, the bulb fila- plastic lamp in actual field use. (Should the new part of the standard four-lamp configuration) approximately 60,000 examples were produced and sold that year. Conventional glass sealed- beam pair of headlamps. This configuration provided a way to gain production use and ment was separately encapsulated. Therefore plastic lamps fail, the vehicle would still have "high/low sealed beam, and the inboard plastie the normal, safe use of the primary outer further use. the risk of fire was reduced, compared to the filament exposed when the glass housing was broken. high beam could be easily retrofitted with the standard glass lamp.) The plastic lamps were manufactured by GEL as part of a development Validating the Concept project funded by GEP and Ford. GEP decided to make some prototype plastic Car was deemed successful, paving the way for The test application on the Lincoln Town headlamps, test them in simulated use to see if they would work over an acceptable period of GEP hired an experienced automotive time. Since GEL was the lighting expert, and at designer/stylist (they don't like to be called this point, they did not want to get too far from stylists!) from Europe, where aerodynamic the project (at least to maintain knowledge of headlamps, made of glass, styled to fit the car what was going on), they agreed to work with were the norm. The designer developed "before GEP and Ford to develop the prototypes. All and after illustrations of existing and poten- agreed that if those tests went well, then the tial vehicle models, graphically showing the next step would be to further prove it out with appearance advantage of smooth, new, flush a production vehicle trial. Until then, no one plastic designs compared to the upright, rec- tangular holes in the otherwise stylish front end had questioned the prevailing assumptions. Prototypes were designed, fabricated, and of most vehicles. It worked. At about this time, GE Lamp withdrew tested. Results were favorable and reviewed with Ford as well as with the appropriate support of the development program. To say agencies. Ford decided to further validate the that both Ford and GEP were disappointed concept in actual field use and requested GEL to would be an understatement. While Ford was manufacture the lamps. The first polycarbonate proficient at the manufacture of plastic parts with some of the largest captive molding facili- headlamp to be used on a production U.S.-built vehicle was a two-piece injection molded ties in the industry, it was convinced that the version of the standard 4" x 6" rectangular high development required a cooperative lamp man- beam-only design-using a halogen capsule ufacturer. Over dinner with a GEP representa- bulb as its light source. It used an injection tive, the Ford vice president of Car Engineering molded lens with an ultraviolet (UV) protective made the Ford position clear. Ford was going to 472 Case V Automotive Headlamps II go ahead with the aerodynamic lamp develop- Questions for Discussion ment. It preferred to partner with GE, as GE had both plastics materials and lighting exper- 1. What is your assessment of the situation? 2. What are the benefits of plastic headlamps? tise. However, it wouldn't refrain from finding another lighting manufacturer and/or another To whom? 3. How would you overcome the objections plastics material supplier and put them together into a team (e.g., a value network) to make of the GM Guide Lamp division? the project happen. The vice president of Ford 4. What is the rationale behind the GEL asked the GEP representative to get that decision to withdraw support from the message back to GE. development? 5. Does it make sense to innovate the offer- Analysis ings of a cash cow? Why? 6. How has GEL impacted the GEP rela- This case represents a situation that is often tionship at Ford? associated with innovation. A few people within 7. What approaches would you take with a company have a bright idea that would benefit them if accepted and implemented. However, other potential customers? 8. How would you address and overcome the current industry situation is characterized by the issues regarding agency approval? a well-established technology and committed 9. What are the key factors likely to deter- manufacturing, combined with external, third- mine success in this application? party government and industry standards devel- oped around the incumbent systems