Use the Solver Simulation Practice spreadsheet and information in the book to derive $15,500 as the lowest cost option for shipping from distribution centers to factories as described on pages 323 through 325 in your textbook.

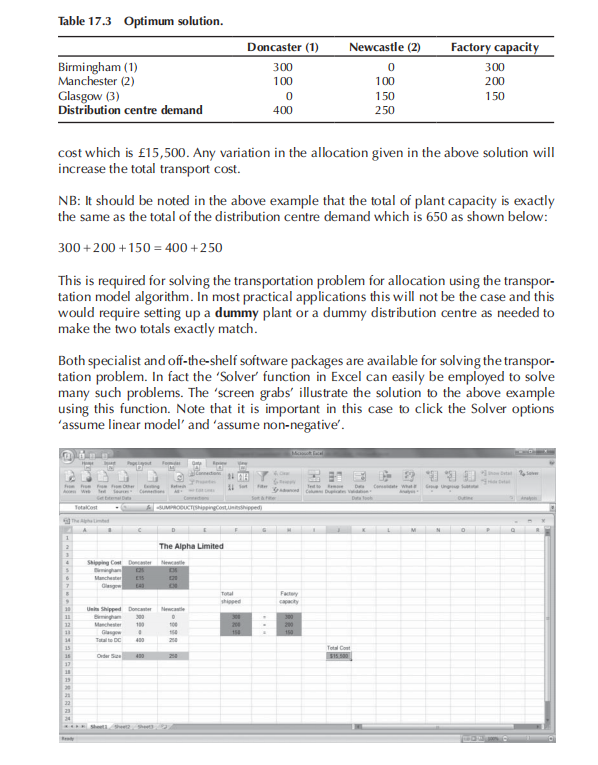

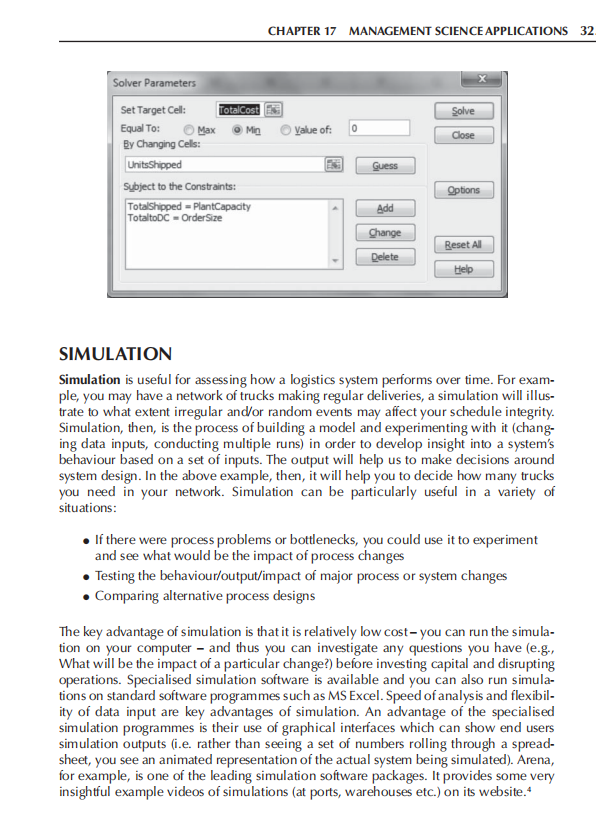

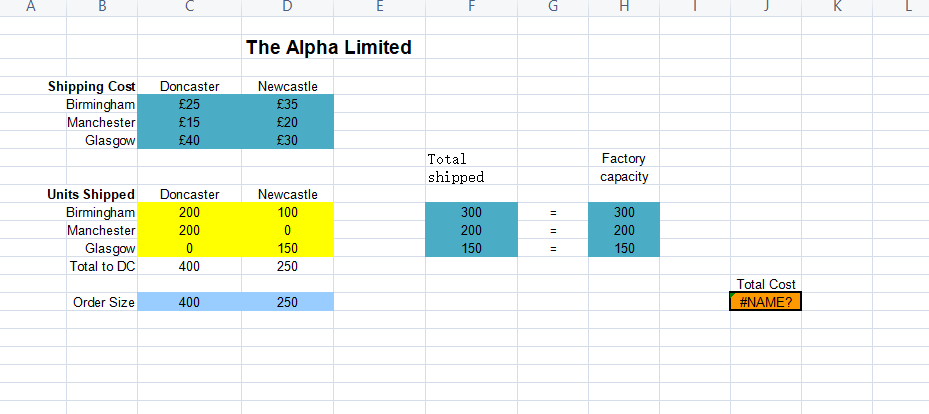

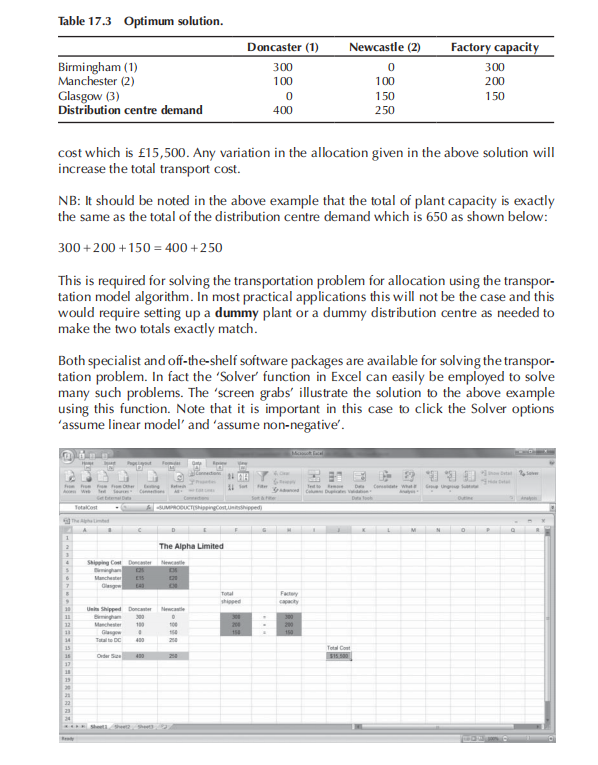

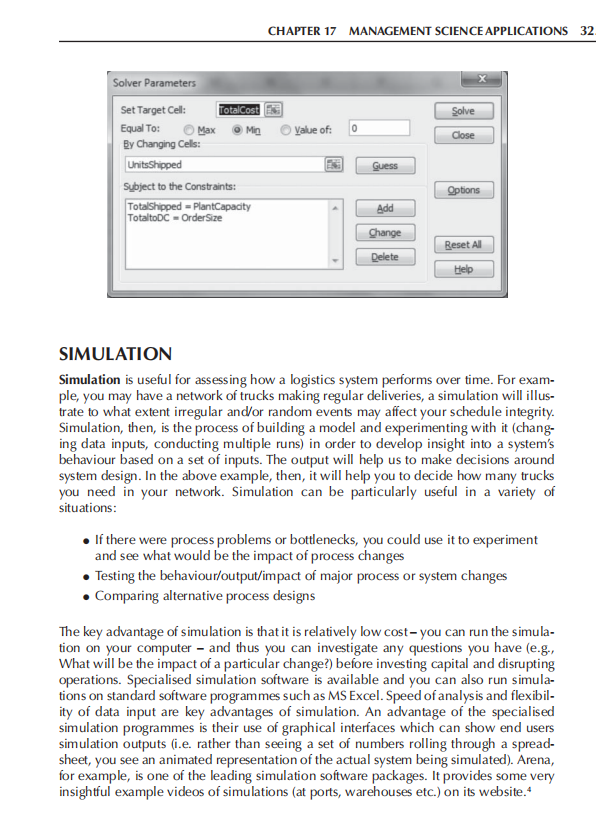

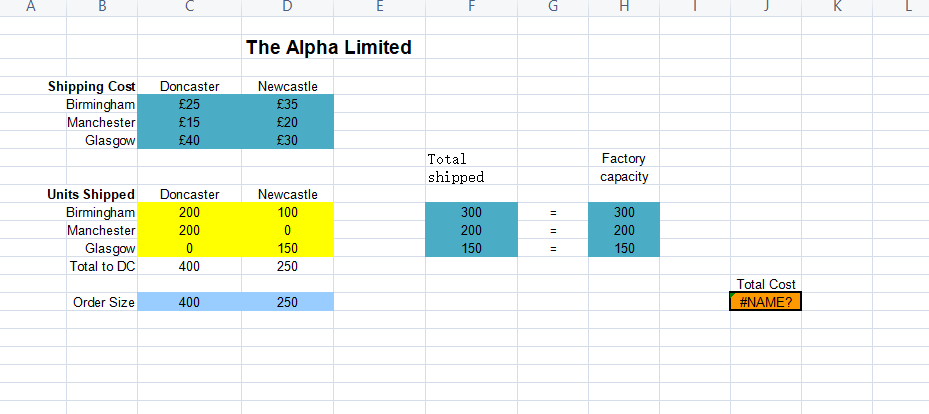

Table 17.3 Optimum solution. Doncaster (1) 300 100 0 400 Birmingham (1) Manchester (2) Glasgow (3) Distribution centre demand Newcastle (2) 0 100 150 250 Factory capacity 300 200 150 cost which is 15,500. Any variation in the allocation given in the above solution will increase the total transport cost. NB: It should be noted in the above example that the total of plant capacity is exactly the same as the total of the distribution centre demand which is 650 as shown below: 300+200 +150 = 400 +250 This is required for solving the transportation problem for allocation using the transpor- tation model algorithm. In most practical applications this will not be the case and this would require setting up a dummy plant or a dummy distribution centre as needed to make the two totals exactly match. Both specialist and off-the-shelf software packages are available for solving the transpor- tation problem. In fact the "Solver' function in Excel can easily be employed to solve many such problems. The 'screen grabs' illustrate the solution to the above example using this function. Note that it is important in this case to click the Solver options 'assume linear model' and 'assume non-negative'. 11 Totalcost BUV PRODUCTS The Alpha Limited thing Total 51500 OS 400 CHAPTER 17 MANAGEMENT SCIENCE APPLICATIONS 32 Solver Parameters Solve Value of: 0 Close Set Target Cell: TotalCost Equal To: Max Min By Changing Cels: Units Shipped Subject to the Constraints: TotalShipped - PlantCapacity TotaltoDC -Order Size Guess Options Add Change Reset All Delete Help SIMULATION Simulation is useful for assessing how a logistics system performs over time. For exam- ple, you may have a network of trucks making regular deliveries, a simulation will illus- trate to what extent irregular and/or random events may affect your schedule integrity. Simulation, then, is the process of building a model and experimenting with it (chang- ing data inputs, conducting multiple runs) in order to develop insight into a system's behaviour based on a set of inputs. The output will help us to make decisions around system design. In the above example, then, it will help you to decide how many trucks you need in your network. Simulation can be particularly useful in a variety of situations: If there were process problems or bottlenecks, you could use it to experiment and see what would be the impact of process changes Testing the behaviour/output/impact of major process or system changes Comparing alternative process designs The key advantage of simulation is that it is relatively low cost - you can run the simula- tion on your computer - and thus you can investigate any questions you have (e.g., What will be the impact of a particular change?) before investing capital and disrupting operations. Specialised simulation software is available and you can also run simula- tions on standard software programmes such as MS Excel. Speed of analysis and flexibil- ity of data input are key advantages of simulation. An advantage of the specialised simulation programmes is their use of graphical interfaces which can show end users simulation outputs (i.e. rather than seeing a set of numbers rolling through a spread- sheet, you see an animated representation of the actual system being simulated). Arena, for example, is one of the leading simulation software packages. It provides some very insightful example videos of simulations (at ports, warehouses etc.) on its website. A B The Alpha Limited Shipping Cost Birmingham Manchester Glasgow Doncaster 25 15 40 Newcastle 35 20 30 Total shipped Factory capacity Units Shipped Birmingham Manchester Glasgow Total to DC Doncaster 200 200 0 400 Newcastle 100 0 150 250 300 200 150 300 200 150 Total Cost #NAME? Order Size 400 250