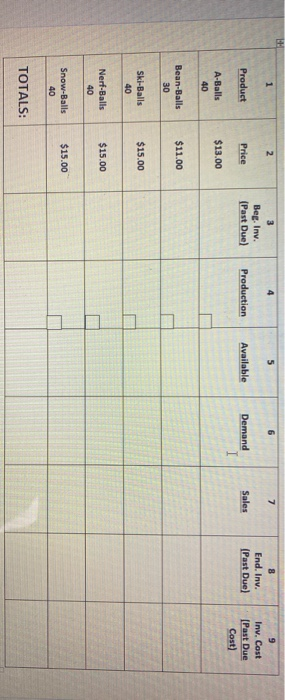

Using the production make a P&L statement

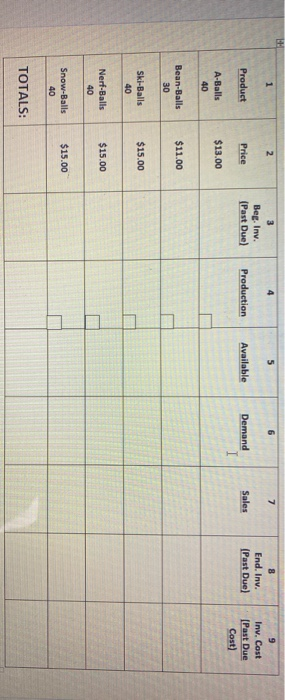

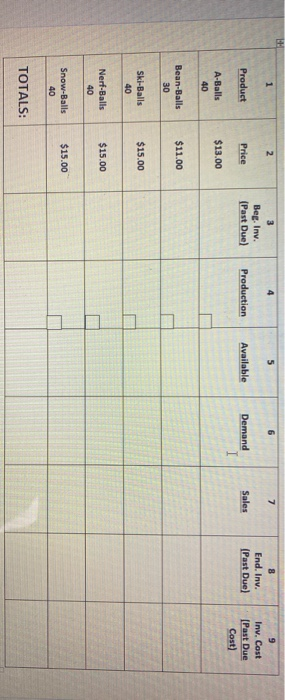

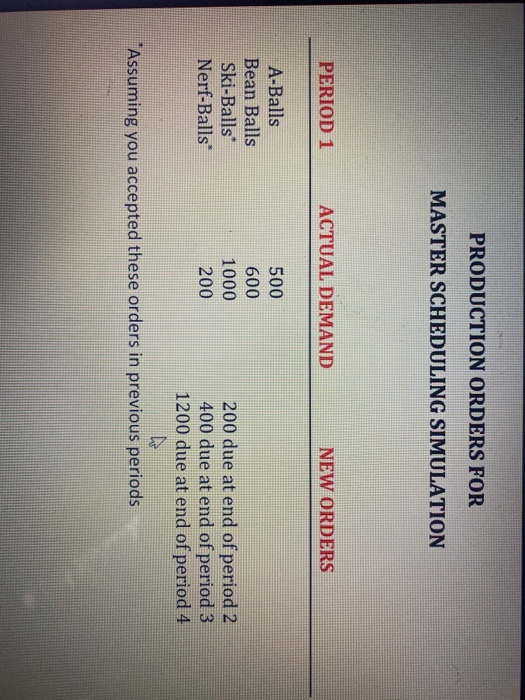

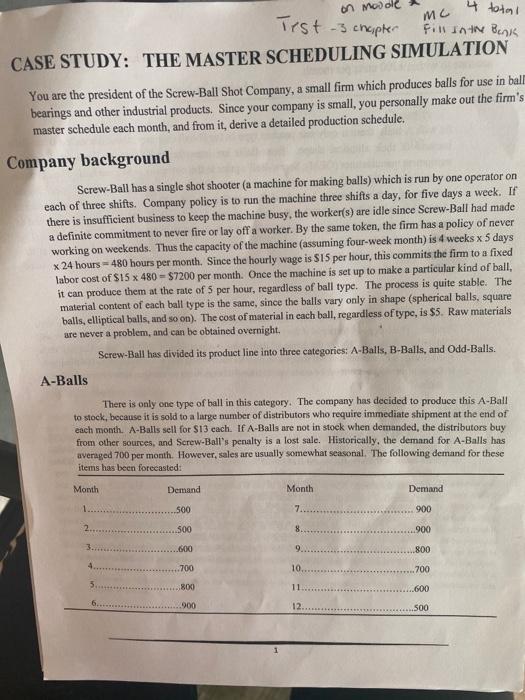

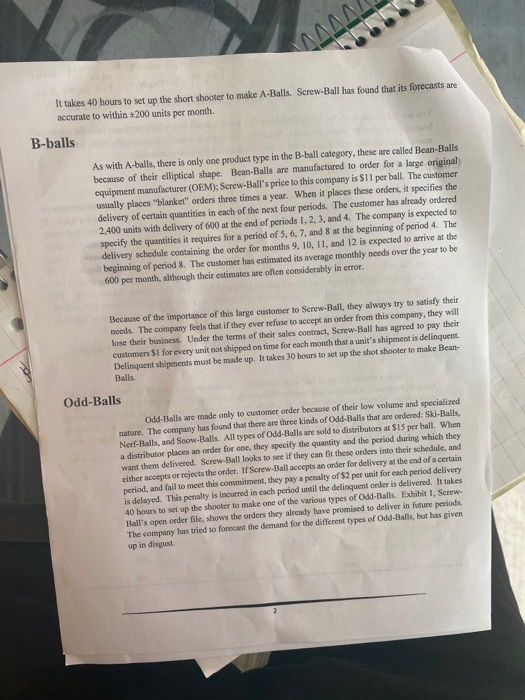

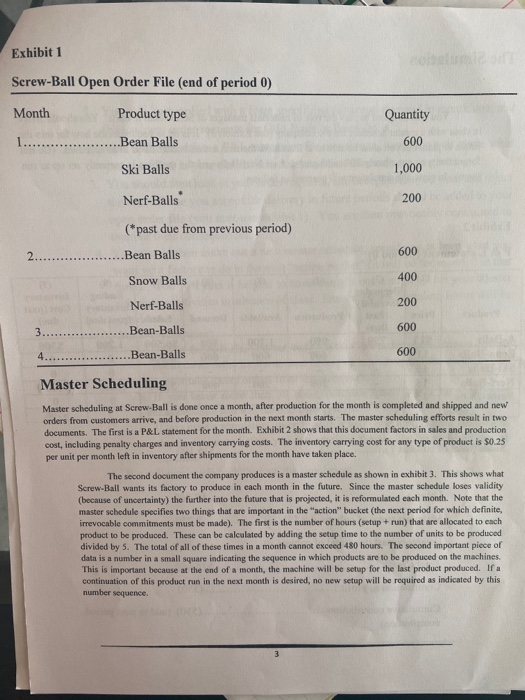

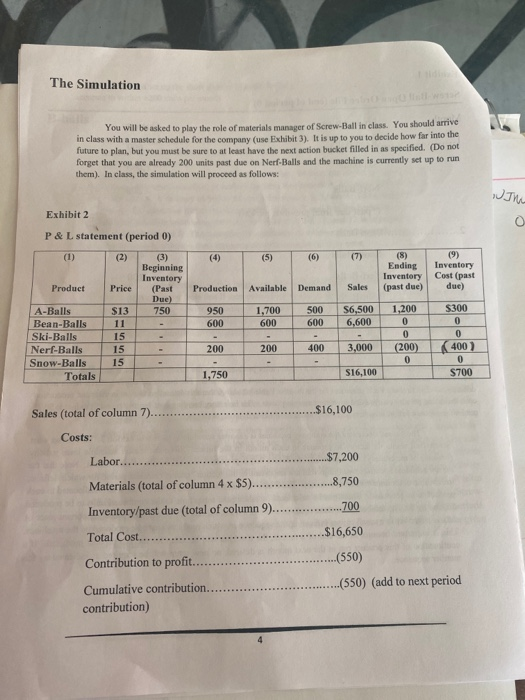

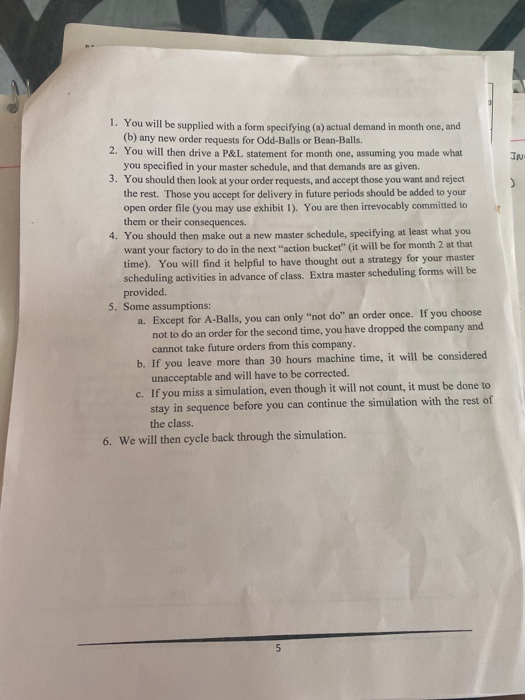

2 5 6 7 Beg. Inv. (Past Due) End. Inv. (Past Due) Product Price Production Available Demand Sales Inv. Cost (Past Due Cost) $13.00 A-Balls 40 Bean-Balls 30 $11.00 $15.00 Ski-Balls 40 Nerf-Balls 40 $15.00 Snow-Balls 40 $15.00 TOTALS: PRODUCTION ORDERS FOR MASTER SCHEDULING SIMULATION PERIOD 1 ACTUAL DEMAND NEW ORDERS A-Balls Bean Balls Ski-Balls Nerf-Balls 500 600 1000 200 200 due at end of period 2 400 due at end of period 3 1200 due at end of period 4 * Assuming you accepted these orders in previous periods . 4 total Test -3 chapter on Modole Fill in the Bank CASE STUDY: THE MASTER SCHEDULING SIMULATION You are the president of the Screw-Ball Shot Company, a small firm which produces balls for use in ball bearings and other industrial products. Since your company is small, you personally make out the firm's master schedule each month, and from it, derive a detailed production schedule. Company background Screw-Ball has a single shot shooter (a machine for making balls) which is run by one operator on each of three shifts. Company policy is to run the machine three shifts a day, for five days a week. If there is insufficient business to keep the machine busy, the worker(s) are idle since Screw-Ball had made a definite commitment to never fire or lay off a worker. By the same token, the firm has a policy of never working on weekends. Thus the capacity of the machine (assuming four-week month) is 4 weeks x 5 days x 24 hours = 480 hours per month. Since the hourly wage is $15 per hour, this commits the firm to a fixed labor cost of $15 x 480 = $7200 per month. Once the machine is set up to make a particular kind of ball, it can produce them at the rate of 5 per hour, regardless of ball type. The process is quite stable. The material content of each ball type is the same, since the balls vary only in shape (spherical balls, square balls, elliptical balls, and so on). The cost of material in each ball, regardless of type, is $5. Raw materials are never a problem, and can be obtained overnight. Screw-Ball has divided its product line into three categories: A-Balls, B-Balls, and Odd-Balls. A-Balls There is only one type of ball in this category. The company has decided to produce this A-Ball to stock, because it is sold to a large number of distributors who require immediate shipment at the end of each month. A-Balls sell for $13 each. If A-Balls are not in stock when demanded, the distributors buy from other sources, and Screw-Ball's penalty is a lost sale. Historically, the demand for A-Balls has averaged 700 per month. However, sales are usually somewhat seasonal. The following demand for these items has been forecasted: Month Demand Month Demand 500 7.. 900 2... ..500 8.. 900 3. 600 9. 800 4. 10. 700 ..700 .800 11 ...600 6. 900 12. .500 1444 It takes 40 hours to set up the short shooter to make A-Balls. Screw-Ball has found that its forecasts are accurate to within +200 units per month B-balls As with A-balls, there is only one product type in the B-ball category, these are called Bean-Balls because of their elliptical shape. Bean-Balls are manufactured to order for a large original equipment manufacturer (OEM); Screw-Ball's price to this company is $Il per ball. The customer usually places "blanket" orders three times a year. When it places these orders, it specifies the delivery of certain quantities in each of the next four periods. The customer has already ordered 2,400 units with delivery of 600 at the end of periods 1, 2, 3, and 4. The company is expected to specify the quantities it requires for a period of 5, 6, 7, and 8 at the beginning of period 4. The delivery schedule containing the order for months 9, 10, 11, and 12 is expected to arrive at the beginning of period 8. The customer has estimated its average monthly needs over the year to be 600 per month, although their estimates are often considerably in error Because of the importance of this large customer to Screw-Ball, they always try to satisfy their needs. The company feels that if they ever refuse to accept an order from this company, they will lose their business. Under the terms of their sales contract, Screw-Ball has agreed to pay their customers $1 for every unit not shipped on time for each month that a unit's shipment is delinquent. Delinquent shipments must be made up. It takes 30 hours to set up the shot shooter to make Bean- Balls Odd-Balls Odd-Balls are made only to customer order because of their low volume and specialized nature. The company has found that there are three kinds of Odd-Balls that are ordered: Ski-Balls, Nerf-Balls, and Snow-Balls. All types of Odd-Balls are sold to distributors at S15 per ball. When a distributor places an order for one, they specify the quantity and the period during which they want them delivered. Screw-Ball looks to see if they can fit these orders into their schedule, and either accepts or rejects the order. If Screw-Ball accepts an order for delivery at the end of a certain period, and fail to meet this commitment, they pay a penalty of $2 per unit for each period delivery is delayed. This penalty is incurred in each period until the delinquent order is delivered. It takes 40 hours to set up the shooter to make one of the various types of Odd-Balls. Exhibit I, Screw Ball's open order file, shows the orders they already have promised to deliver in future periods. The company has tried to forecast the demand for the different types of Odd-Balls, but has given up in disgust. Exhibit 1 Screw-Ball Open Order File (end of period 0) Month Product type Quantity .Bean Balls 600 Ski Balls 1,000 Nerf-Balls 200 (*past due from previous period) 2... 600 .Bean Balls Snow Balls 400 Nerf-Balls 200 3... .Bean-Balls 600 4.... .Bean-Balls 600 Master Scheduling Master scheduling at Screw-Ball is done once a month, after production for the month is completed and shipped and new orders from customers arrive, and before production in the next month starts. The master scheduling efforts result in two documents. The first is a P&L statement for the month. Exhibit 2 shows that this document factors in sales and production cost, including penalty charges and inventory carrying costs. The inventory carrying cost for any type of product is $0.25 per unit per month left in inventory after shipments for the month have taken place. The second document the company produces is a master schedule as shown in exhibit 3. This shows what Screw-Ball wants its factory to produce in each month in the future. Since the master schedule loses validity (because of uncertainty) the further into the future that is projected, it is reformulated each month. Note that the master schedule specifies two things that are important in the "action" bucket (the next period for which definite, irrevocable commitments must be made). The first is the number of hours (setup + run) that are allocated to each product to be produced. These can be calculated by adding the setup time to the number of units to be produced divided by S. The total of all of these times in a month cannot exceed 480 hours. The second important piece of data is a number in a small square indicating the sequence in which products are to be produced on the machines. This is important because at the end of a month, the machine will be setup for the last product produced. If a continuation of this product run in the next month is desired, no new setup will be required as indicated by this number sequence The Simulation You will be asked to play the role of materials manager of Screw-Ball in class. You should arrive in class with a master schedule for the company (use Exhibit 3). It is up to you to decide how far into the future to plan, but you must be sure to at least have the next action bucket filled in as specified. (Do not forget that you are already 200 units past due on Nerf-Balls and the machine is currently set up to run them). In class, the simulation will proceed as follows: JJ ML Exhibit 2 O P & L statement (period 0) (2) (5) (6) (8) Ending Inventory (past due) (3) Beginning Inventory (Past Due) 750 (9) Inventory Cost (past due) Product Price Production Available Demand Sales 1,200 950 600 1.700 600 500 600 $6,500 6,600 A-Balls Bean-Balls Ski-Balls Nerf-Balls Snow-Balls Totals $13 11 15 15 15 $300 0 0 200 200 400 3,000 0 (200) 0 (400) 0 $700 1,750 S16,100 Sales (total of column 7).... $16,100 Costs: Labor..... $7,200 .8,750 Materials (total of column 4 x $5)... Inventory/past due (total of column 9)...... .700 Total Cost..... .$16,650 Contribution to profit... --(550) (550) (add to next period Cumulative contribution.. contribution) 0 TNU 1. You will be supplied with a form specifying (a) actual demand in month one, and (b) any new order requests for Odd-Balls or Bean-Balls. 2. You will then drive a P&L statement for month one, assuming you made what you specified in your master schedule, and that demands are as given. 3. You should then look at your order requests, and accept those you want and reject the rest. Those you accept for delivery in future periods should be added to your open order file you may use exhibit 1). You are then irrevocably committed to them or their consequences. 4. You should then make out a new master schedule, specifying at least what you want your factory to do in the next "action bucket" (it will be for month 2 at that time). You will find it helpful to have thought out a strategy for your master scheduling activities in advance of class. Extra master scheduling forms will be provided. 5. Some assumptions: a. Except for A-Balls, you can only "not do" an order once. If you choose not to do an order for the second time, you have dropped the company and cannot take future orders from this company. b. If you leave more than 30 hours machine time, it will be considered unacceptable and will have to be corrected. c. If you miss a simulation, even though it will not count, it must be done to stay in sequence before you can continue the simulation with the rest of the class. 6. We will then cycle back through the simulation. 2 5 6 7 Beg. Inv. (Past Due) End. Inv. (Past Due) Product Price Production Available Demand Sales Inv. Cost (Past Due Cost) $13.00 A-Balls 40 Bean-Balls 30 $11.00 $15.00 Ski-Balls 40 Nerf-Balls 40 $15.00 Snow-Balls 40 $15.00 TOTALS: PRODUCTION ORDERS FOR MASTER SCHEDULING SIMULATION PERIOD 1 ACTUAL DEMAND NEW ORDERS A-Balls Bean Balls Ski-Balls Nerf-Balls 500 600 1000 200 200 due at end of period 2 400 due at end of period 3 1200 due at end of period 4 * Assuming you accepted these orders in previous periods . 4 total Test -3 chapter on Modole Fill in the Bank CASE STUDY: THE MASTER SCHEDULING SIMULATION You are the president of the Screw-Ball Shot Company, a small firm which produces balls for use in ball bearings and other industrial products. Since your company is small, you personally make out the firm's master schedule each month, and from it, derive a detailed production schedule. Company background Screw-Ball has a single shot shooter (a machine for making balls) which is run by one operator on each of three shifts. Company policy is to run the machine three shifts a day, for five days a week. If there is insufficient business to keep the machine busy, the worker(s) are idle since Screw-Ball had made a definite commitment to never fire or lay off a worker. By the same token, the firm has a policy of never working on weekends. Thus the capacity of the machine (assuming four-week month) is 4 weeks x 5 days x 24 hours = 480 hours per month. Since the hourly wage is $15 per hour, this commits the firm to a fixed labor cost of $15 x 480 = $7200 per month. Once the machine is set up to make a particular kind of ball, it can produce them at the rate of 5 per hour, regardless of ball type. The process is quite stable. The material content of each ball type is the same, since the balls vary only in shape (spherical balls, square balls, elliptical balls, and so on). The cost of material in each ball, regardless of type, is $5. Raw materials are never a problem, and can be obtained overnight. Screw-Ball has divided its product line into three categories: A-Balls, B-Balls, and Odd-Balls. A-Balls There is only one type of ball in this category. The company has decided to produce this A-Ball to stock, because it is sold to a large number of distributors who require immediate shipment at the end of each month. A-Balls sell for $13 each. If A-Balls are not in stock when demanded, the distributors buy from other sources, and Screw-Ball's penalty is a lost sale. Historically, the demand for A-Balls has averaged 700 per month. However, sales are usually somewhat seasonal. The following demand for these items has been forecasted: Month Demand Month Demand 500 7.. 900 2... ..500 8.. 900 3. 600 9. 800 4. 10. 700 ..700 .800 11 ...600 6. 900 12. .500 1444 It takes 40 hours to set up the short shooter to make A-Balls. Screw-Ball has found that its forecasts are accurate to within +200 units per month B-balls As with A-balls, there is only one product type in the B-ball category, these are called Bean-Balls because of their elliptical shape. Bean-Balls are manufactured to order for a large original equipment manufacturer (OEM); Screw-Ball's price to this company is $Il per ball. The customer usually places "blanket" orders three times a year. When it places these orders, it specifies the delivery of certain quantities in each of the next four periods. The customer has already ordered 2,400 units with delivery of 600 at the end of periods 1, 2, 3, and 4. The company is expected to specify the quantities it requires for a period of 5, 6, 7, and 8 at the beginning of period 4. The delivery schedule containing the order for months 9, 10, 11, and 12 is expected to arrive at the beginning of period 8. The customer has estimated its average monthly needs over the year to be 600 per month, although their estimates are often considerably in error Because of the importance of this large customer to Screw-Ball, they always try to satisfy their needs. The company feels that if they ever refuse to accept an order from this company, they will lose their business. Under the terms of their sales contract, Screw-Ball has agreed to pay their customers $1 for every unit not shipped on time for each month that a unit's shipment is delinquent. Delinquent shipments must be made up. It takes 30 hours to set up the shot shooter to make Bean- Balls Odd-Balls Odd-Balls are made only to customer order because of their low volume and specialized nature. The company has found that there are three kinds of Odd-Balls that are ordered: Ski-Balls, Nerf-Balls, and Snow-Balls. All types of Odd-Balls are sold to distributors at S15 per ball. When a distributor places an order for one, they specify the quantity and the period during which they want them delivered. Screw-Ball looks to see if they can fit these orders into their schedule, and either accepts or rejects the order. If Screw-Ball accepts an order for delivery at the end of a certain period, and fail to meet this commitment, they pay a penalty of $2 per unit for each period delivery is delayed. This penalty is incurred in each period until the delinquent order is delivered. It takes 40 hours to set up the shooter to make one of the various types of Odd-Balls. Exhibit I, Screw Ball's open order file, shows the orders they already have promised to deliver in future periods. The company has tried to forecast the demand for the different types of Odd-Balls, but has given up in disgust. Exhibit 1 Screw-Ball Open Order File (end of period 0) Month Product type Quantity .Bean Balls 600 Ski Balls 1,000 Nerf-Balls 200 (*past due from previous period) 2... 600 .Bean Balls Snow Balls 400 Nerf-Balls 200 3... .Bean-Balls 600 4.... .Bean-Balls 600 Master Scheduling Master scheduling at Screw-Ball is done once a month, after production for the month is completed and shipped and new orders from customers arrive, and before production in the next month starts. The master scheduling efforts result in two documents. The first is a P&L statement for the month. Exhibit 2 shows that this document factors in sales and production cost, including penalty charges and inventory carrying costs. The inventory carrying cost for any type of product is $0.25 per unit per month left in inventory after shipments for the month have taken place. The second document the company produces is a master schedule as shown in exhibit 3. This shows what Screw-Ball wants its factory to produce in each month in the future. Since the master schedule loses validity (because of uncertainty) the further into the future that is projected, it is reformulated each month. Note that the master schedule specifies two things that are important in the "action" bucket (the next period for which definite, irrevocable commitments must be made). The first is the number of hours (setup + run) that are allocated to each product to be produced. These can be calculated by adding the setup time to the number of units to be produced divided by S. The total of all of these times in a month cannot exceed 480 hours. The second important piece of data is a number in a small square indicating the sequence in which products are to be produced on the machines. This is important because at the end of a month, the machine will be setup for the last product produced. If a continuation of this product run in the next month is desired, no new setup will be required as indicated by this number sequence The Simulation You will be asked to play the role of materials manager of Screw-Ball in class. You should arrive in class with a master schedule for the company (use Exhibit 3). It is up to you to decide how far into the future to plan, but you must be sure to at least have the next action bucket filled in as specified. (Do not forget that you are already 200 units past due on Nerf-Balls and the machine is currently set up to run them). In class, the simulation will proceed as follows: JJ ML Exhibit 2 O P & L statement (period 0) (2) (5) (6) (8) Ending Inventory (past due) (3) Beginning Inventory (Past Due) 750 (9) Inventory Cost (past due) Product Price Production Available Demand Sales 1,200 950 600 1.700 600 500 600 $6,500 6,600 A-Balls Bean-Balls Ski-Balls Nerf-Balls Snow-Balls Totals $13 11 15 15 15 $300 0 0 200 200 400 3,000 0 (200) 0 (400) 0 $700 1,750 S16,100 Sales (total of column 7).... $16,100 Costs: Labor..... $7,200 .8,750 Materials (total of column 4 x $5)... Inventory/past due (total of column 9)...... .700 Total Cost..... .$16,650 Contribution to profit... --(550) (550) (add to next period Cumulative contribution.. contribution) 0 TNU 1. You will be supplied with a form specifying (a) actual demand in month one, and (b) any new order requests for Odd-Balls or Bean-Balls. 2. You will then drive a P&L statement for month one, assuming you made what you specified in your master schedule, and that demands are as given. 3. You should then look at your order requests, and accept those you want and reject the rest. Those you accept for delivery in future periods should be added to your open order file you may use exhibit 1). You are then irrevocably committed to them or their consequences. 4. You should then make out a new master schedule, specifying at least what you want your factory to do in the next "action bucket" (it will be for month 2 at that time). You will find it helpful to have thought out a strategy for your master scheduling activities in advance of class. Extra master scheduling forms will be provided. 5. Some assumptions: a. Except for A-Balls, you can only "not do" an order once. If you choose not to do an order for the second time, you have dropped the company and cannot take future orders from this company. b. If you leave more than 30 hours machine time, it will be considered unacceptable and will have to be corrected. c. If you miss a simulation, even though it will not count, it must be done to stay in sequence before you can continue the simulation with the rest of the class. 6. We will then cycle back through the simulation