Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Very Good Supply Co. uses a five-step process to manufacture their colored dot sheets. The process entails fixing different color dots to the order

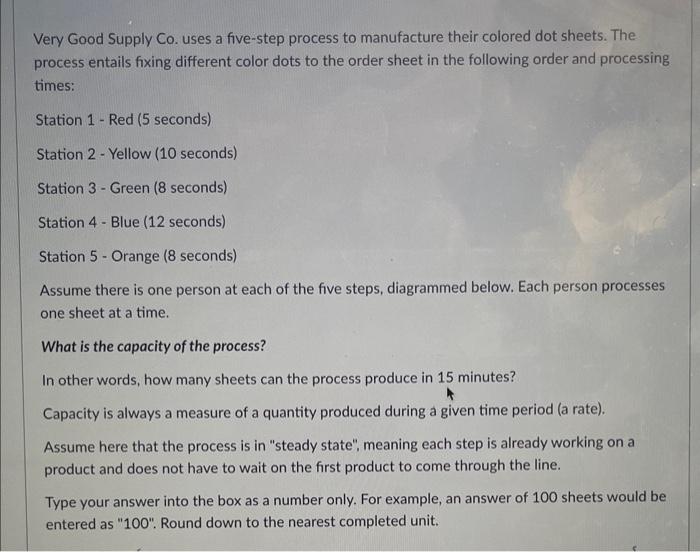

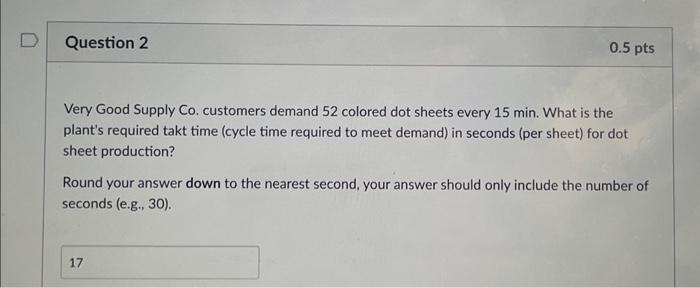

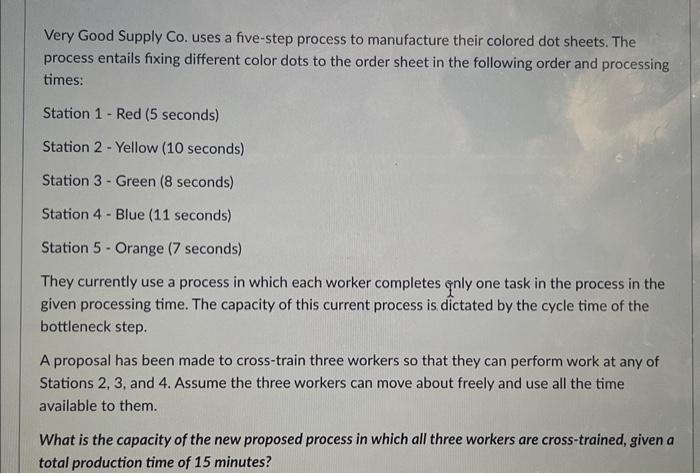

Very Good Supply Co. uses a five-step process to manufacture their colored dot sheets. The process entails fixing different color dots to the order sheet in the following order and processing times: Station 1 - Red (5 seconds) Station 2 - Yellow (10 seconds) Station 3 - Green (8 seconds) Station 4- Blue (12 seconds) Station 5 - Orange (8 seconds) Assume there is one person at each of the five steps, diagrammed below. Each person processes one sheet at a time. What is the capacity of the process? In other words, how many sheets can the process produce in 15 minutes? Capacity is always a measure of a quantity produced during a given time period (a rate). Assume here that the process is in "steady state", meaning each step is already working on a product and does not have to wait on the first product to come through the line. Type your answer into the box as a number only. For example, an answer of 100 sheets would be entered as "100". Round down to the nearest completed unit. Question 2 0.5 pts Very Good Supply Co. customers demand 52 colored dot sheets every 15 min. What is the plant's required takt time (cycle time required to meet demand) in seconds (per sheet) for dot sheet production? Round your answer down to the nearest second, your answer should only include the number of seconds (e.g., 30). 17 Very Good Supply Co. uses a five-step process to manufacture their colored dot sheets. The process entails fixing different color dots to the order sheet in the following order and processing times: Station 1 Red (5 seconds) - Station 2 - Yellow (10 seconds) Station 3 Green (8 seconds) Station 4 Blue (11 seconds) Station 5 Orange (7 seconds) They currently use a process in which each worker completes qnly one task in the process in the given processing time. The capacity of this current process is dictated by the cycle time of the bottleneck step. A proposal has been made to cross-train three workers so that they can perform work at any of Stations 2, 3, and 4. Assume the three workers can move about freely and use all the time available to them. What is the capacity of the new proposed process in which all three workers are cross-trained, given a total production time of 15 minutes?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

The images provided contain three separate problems that relate to the capacity of a manufacturing process at Very Good Supply Co which involves a fivestep process for creating colored dot sheets Lets ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started