Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Welcome to Supply Chain. Touching every part of the organisation, partnering with over 75,000 suppliers, employing over 110,000 people in 190 countries, we're the

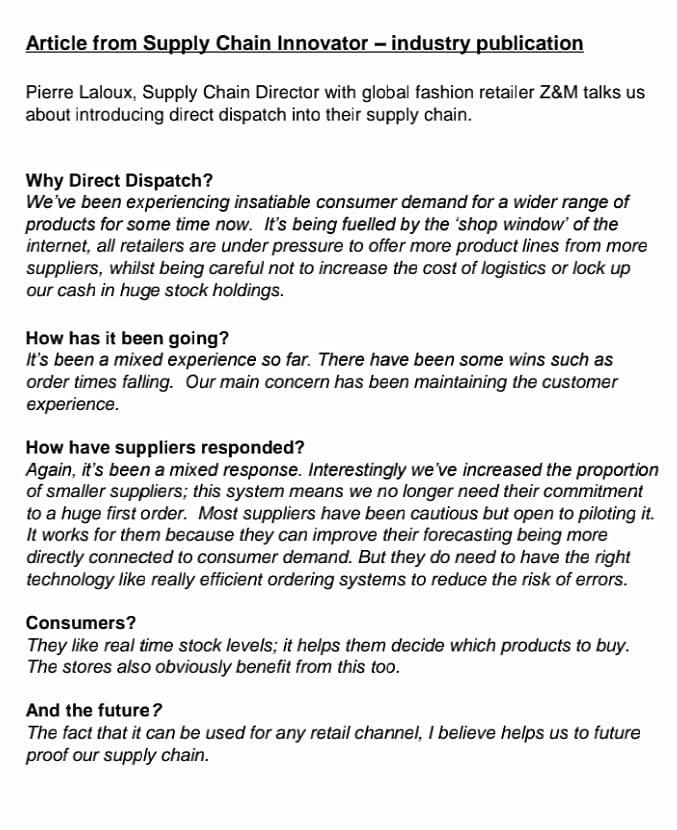

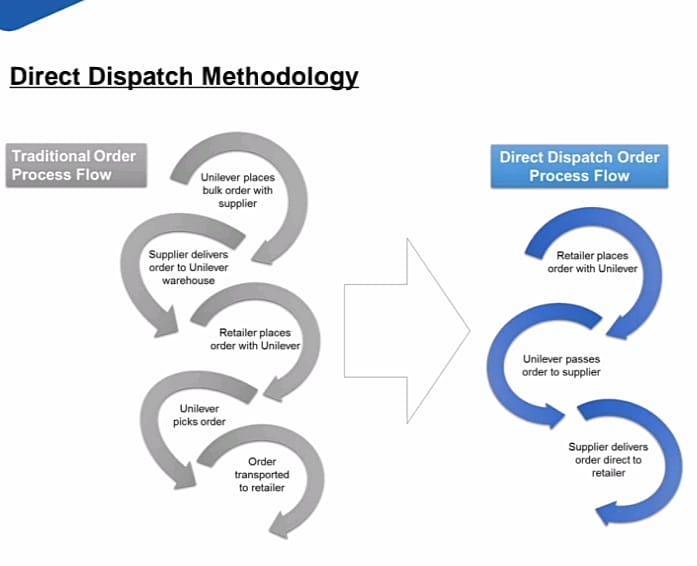

Welcome to Supply Chain. Touching every part of the organisation, partnering with over 75,000 suppliers, employing over 110,000 people in 190 countries, we're the backbone of the business where every decision can have a huge impact - I'm sure you'll find it an exciting place to work! Kate Levine is a new Strategic Planning Manager who has recently joined supply chain from Marketing. She has a video conference with the Supply Chain team in Argentina later today, who has asked for her view on the 'direct dispatch' methodology. I would like you to provide Kate with a summary of 'direct dispatch', its benefits and its risks, so that she's fully briefed for the call. In summary, direct dispatch is an innovation used in some of our markets where products are dispatched from a producer or supplier direct to the customer, rather than via our distribution centres. There are potentially huge cost savings and efficiencies to be gained. There have been some successes and some failures, we're continuously learning and improving how we do things, but it may not be right for every market or brand. I've sent you some information from one of our teams who have adopted it and an article about a clothing retailer's experiences. Article from Supply Chain Innovator - industry publication Pierre Laloux, Supply Chain Director with global fashion retailer Z&M talks us about introducing direct dispatch into their supply chain. Why Direct Dispatch? We've been experiencing insatiable consumer demand for a wider range of products for some time now. It's being fuelled by the 'shop window' of the internet, all retailers are under pressure to offer more product lines from more suppliers, whilst being careful not to increase the cost of logistics or lock up our cash in huge stock holdings. How has it been going? It's been a mixed experience so far. There have been some wins such as order times falling. Our main concern has been maintaining the customer experience. How have suppliers responded? Again, it's been a mixed response. Interestingly we've increased the proportion of smaller suppliers; this system means we no longer need their commitment to a huge first order. Most suppliers have been cautious but open to piloting it. It works for them because they can improve their forecasting being more directly connected to consumer demand. But they do need to have the right technology like really efficient ordering systems to reduce the risk of errors. Consumers? They like real time stock levels; it helps them decide which products to buy. The stores also obviously benefit from this too. And the future? The fact that it can be used for any retail channel, I believe helps us to future proof our supply chain. Direct Dispatch Methodology Traditional Order Process Flow Unilever places bulk order with supplier Supplier delivers order to Unilever warehouse c Retailer places order with Unilever Unilever picks order Order transported to retailer Direct Dispatch Order Process Flow Retailer places order with Unilever Unilever passes order to supplier Supplier delivers order direct to retailer Question 4 of 4 Recorded Question Let's move on to a slightly longer case study. You will now watch a video about the Supply Chain Function. You will then have 10 minutes to review the business problem, come up with a solution and prepare to present your recommendations. After the 10 minutes of preparation time, you will have up to 5 minutes of recording time to share your solution with us. As part of your response, please cover: What in your opinion is the biggest benefit and why? What in your opinion is the most serious risk and why? What do you believe is the best way to overcome this risk? How does direct dispatch fit with Unilever's goals? Do you think, in principle, direct dispatch could work for every type of product? Pier-Luigi Sigismondi- Chiet Supply Chain Officer Hello everyone my name is Pier-Luigi Sigismondi. I've been in this company, Unilever, for about 18 months. I'm an industrial engineer from Georgia Tech and I've actually been in the Supply Chain operations sector for almost 20 years of my career. I started in the consumer goods industry ever since the late 90s, exploring all the areas of the supply chain operations strategies and I can say that it's been a very exciting journey ever since then. Unilever is a big company and I'm also proud to say that Unilever's supply chain is also focused on our customers and our consumers, we're passionate about quality. We want to work and improve the equity of our brands every day and working with customers to improve our service levels is mandatory for us. We're actually looking for ways to increase the perceived service that we provide to many of our key accounts across the globe. Our mission is to really become the best supply chain in the industry. I've been working very hard ever since I joined this company to raise the ambition to become the best and we are perfectly on track together. We have been putting a lot of capabilities lately in this company to develop the depth but also the breadth from a strategic point of view to actually bring our performance to world class standards. We're defining, for each of our major categories global supply chain strategies which are basically looking for ways to deploy globe. We're also looking for ways to deploy our assets and leverage our capacity globally by looking for ways to export more between different continents. To do that we require a lot of strategic thinking and also an open minded business approach. We believe that there is no supply chain that can be the best without full integration with the business, full understanding of our P&L, how it works and in a way also how we create value in the long term for this business. It all starts with the way in which we work with our suppliers and how we can leverage with open innovation, new ingredients, new materials that can lift the brand equity of our products whilst at the same time having a more competitive cost of our raw packaging materials and overall operations. On the other hand, we are also looking at manufacturing strategies that are fully embedded in the business strategies of each of the categories and we have seen major opportunities to deploy those investments which are required to make our factories bigger and even more competitive over time. So the challenge is: where do we go from here? What can we do to create additional value for our business? And this is precisely where the experience in supply chain but also the business understanding is vital for us to keep lifting the bar and to get us to the place we want to be. So, I'm very excited about the journey where place we want to be. So, I'm very excited about the journey where we're at right now. This is a very energising company. It's a company that is very open minded, that is always looking for innovation, looking for new ways of competing. We're benchmarking constantly any company that is competing with us, both on a global basis but also very locally and that's, again, a capability that we have and that we need to reinforce by thinking more from the business end. It's very exciting. I'm not trying to project a picture which is far from reality; it is actually what I live day and night. So thank-you very much and I wish you all the best. Email To: You From: Alicia Marino, Supply Chain Manager, Spain Subject: Experiences of direct dispatch Hi and welcome to Unilever I've been asked to send you a summary of our main learning points from our experience of adopting direct dispatch with an external supplier of Sunsilk. There are two I would highlight: Visibility of data: We and our retail customers need accurate data on stock levels - as if it's held in our own warehouse. We invested in integrating order management systems with the supplier's systems, and real time stock visibility systems gave everyone more confidence. A 'whiteboard' tool helped us communicate with suppliers for example by adding comments to a specific order. Dispatch documentation and labelling: There were some situations where the product arrived without Unilever or Sunsilk branding or with poor labelling; our concern was damage to our brand reputation. We resolved it by giving our supplier cost effective and straightforward document and labelling production facilities. This is, however, just one example of how important quality assurance processes are when adopting a new methodology like direct dispatch. I hope this is useful Alicia Unilever Alicia Marino, Supply Chain Manager, Spain Welcome to Supply Chain. Touching every part of the organisation, partnering with over 75,000 suppliers, employing over 110,000 people in 190 countries, we're the backbone of the business where every decision can have a huge impact - I'm sure you'll find it an exciting place to work! Kate Levine is a new Strategic Planning Manager who has recently joined supply chain from Marketing. She has a video conference with the Supply Chain team in Argentina later today, who has asked for her view on the 'direct dispatch' methodology. I would like you to provide Kate with a summary of 'direct dispatch', its benefits and its risks, so that she's fully briefed for the call. In summary, direct dispatch is an innovation used in some of our markets where products are dispatched from a producer or supplier direct to the customer, rather than via our distribution centres. There are potentially huge cost savings and efficiencies to be gained. There have been some successes and some failures, we're continuously learning and improving how we do things, but it may not be right for every market or brand. I've sent you some information from one of our teams who have adopted it and an article about a clothing retailer's experiences. Article from Supply Chain Innovator - industry publication Pierre Laloux, Supply Chain Director with global fashion retailer Z&M talks us about introducing direct dispatch into their supply chain. Why Direct Dispatch? We've been experiencing insatiable consumer demand for a wider range of products for some time now. It's being fuelled by the 'shop window' of the internet, all retailers are under pressure to offer more product lines from more suppliers, whilst being careful not to increase the cost of logistics or lock up our cash in huge stock holdings. How has it been going? It's been a mixed experience so far. There have been some wins such as order times falling. Our main concern has been maintaining the customer experience. How have suppliers responded? Again, it's been a mixed response. Interestingly we've increased the proportion of smaller suppliers; this system means we no longer need their commitment to a huge first order. Most suppliers have been cautious but open to piloting it. It works for them because they can improve their forecasting being more directly connected to consumer demand. But they do need to have the right technology like really efficient ordering systems to reduce the risk of errors. Consumers? They like real time stock levels; it helps them decide which products to buy. The stores also obviously benefit from this too. And the future? The fact that it can be used for any retail channel, I believe helps us to future proof our supply chain. Direct Dispatch Methodology Traditional Order Process Flow Unilever places bulk order with supplier Supplier delivers order to Unilever warehouse c Retailer places order with Unilever Unilever picks order Order transported to retailer Direct Dispatch Order Process Flow Retailer places order with Unilever Unilever passes order to supplier Supplier delivers order direct to retailer Question 4 of 4 Recorded Question Let's move on to a slightly longer case study. You will now watch a video about the Supply Chain Function. You will then have 10 minutes to review the business problem, come up with a solution and prepare to present your recommendations. After the 10 minutes of preparation time, you will have up to 5 minutes of recording time to share your solution with us. As part of your response, please cover: What in your opinion is the biggest benefit and why? What in your opinion is the most serious risk and why? What do you believe is the best way to overcome this risk? How does direct dispatch fit with Unilever's goals? Do you think, in principle, direct dispatch could work for every type of product? Pier-Luigi Sigismondi- Chief Supply Chain Officer Hello everyone my name is Pier-Luigi Sigismondi. I've been in this company, Unilever, for about 18 months. I'm an industrial engineer from Georgia Tech and I've actually been in the Supply Chain operations sector for almost 20 years of my career. I started in the consumer goods industry ever since the late 90s, exploring all the areas of the supply chain operations strategies and I can say that it's been a very exciting journey ever since then. Unilever is a big company and I'm also proud to say that Unilever's supply chain is also focused on our customers and our consumers, we're passionate about quality. We want to work and improve the equity of our brands every day and working with customers to improve our service levels is mandatory for us. We're actually looking for ways to increase the perceived service that we provide to many of our key accounts across the globe. Our mission is to really become the best supply chain in the industry. I've been working very hard ever since I joined this company to raise the ambition to become the best and we are perfectly on track together. We have been putting a lot of capabilities lately in this company to develop the depth but also the breadth from a strategic point of view to actually bring our performance to world class standards. We're defining, for each of our major categories global supply chain strategies which are basically looking for ways to deploy globe. We're also looking for ways to deploy our assets and leverage our capacity globally by looking for ways to export more between different continents. To do that we require a lot of strategic thinking and also an open minded business approach. We believe that there is no supply chain that can be the best without full integration with the business, full understanding of our P&L, how it works and in a way also how we create value in the long term for this business. It all starts with the way in which we work with our suppliers and how we can leverage with open innovation, new ingredients, new materials that can lift the brand equity of our products whilst at the same time having a more competitive cost of our raw packaging materials and overall operations. On the other hand, we are also looking at manufacturing strategies that are fully embedded in the business strategies of each of the categories and we have seen major opportunities to deploy those investments which are required to make our factories bigger and even more competitive over time. So the challenge is: where do we go from here? What can we do to create additional value for our business? And this is precisely where the experience in supply chain but also the business understanding is vital for us to keep lifting the bar and to get us to the place we want to be. So, I'm very excited about the journey where place we want to be. So, I'm very excited about the journey where we're at right now. This is a very energising company. It's a company that is very open minded, that is always looking for innovation, looking for new ways of competing. We're benchmarking constantly any company that is competing with us, both on a global basis but also very locally and that's, again, a capability that we have and that we need to reinforce by thinking more from the business end. It's very exciting. I'm not trying to project a picture which is far from reality; it is actually what I live day and night. So thank-you very much and I wish you all the best. Email To: You From: Alicia Marino, Supply Chain Manager, Spain Subject: Experiences of direct dispatch Hi and welcome to Unilever I've been asked to send you a summary of our main learning points from our experience of adopting direct dispatch with an external supplier of Sunsilk. There are two I would highlight: Visibility of data: We and our retail customers need accurate data on stock levels - as if it's held in our own warehouse. We invested in integrating order management systems with the supplier's systems, and real time stock visibility systems gave everyone more confidence. A 'whiteboard' tool helped us communicate with suppliers for example by adding comments to a specific order. Dispatch documentation and labelling: There were some situations where the product arrived without Unilever or Sunsilk branding or with poor labelling; our concern was damage to our brand reputation. We resolved it by giving our supplier cost effective and straightforward document and labelling production facilities. This is, however, just one example of how important quality assurance processes are when adopting a new methodology like direct dispatch. I hope this is useful Alicia Unilever Alicia Marino, Supply Chain Manager, Spain

Step by Step Solution

★★★★★

3.39 Rating (146 Votes )

There are 3 Steps involved in it

Step: 1

Direct dispatch is an innovative approach used in some markets where products are dispatched directly from a producer or supplier to the customer bypa...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started