Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Western Chassis produces high-quality polished steel and aluminum sheeting and two lines of industrial chassis for the rack mounting of Internet routers, modems, and

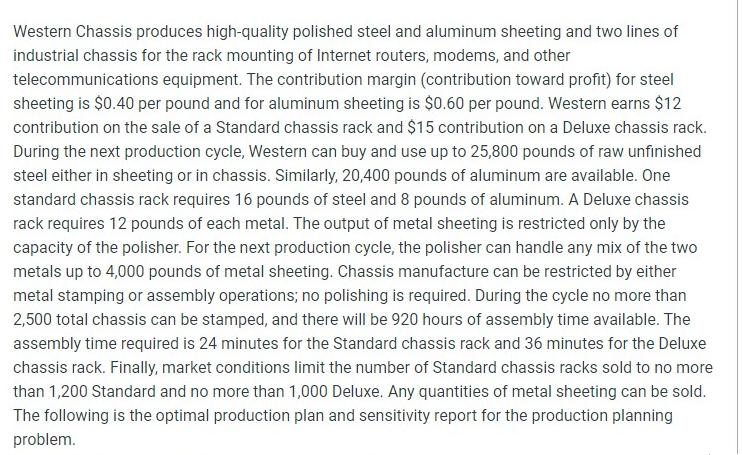

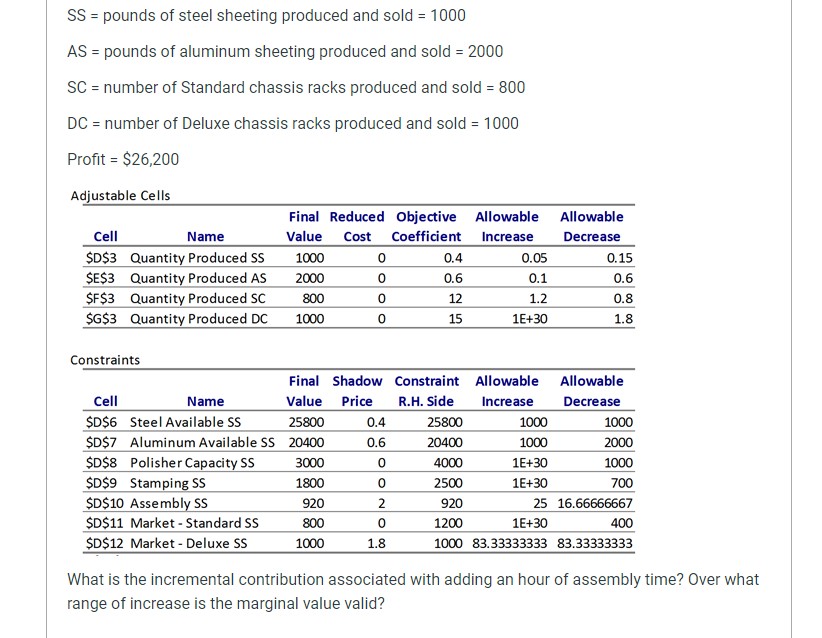

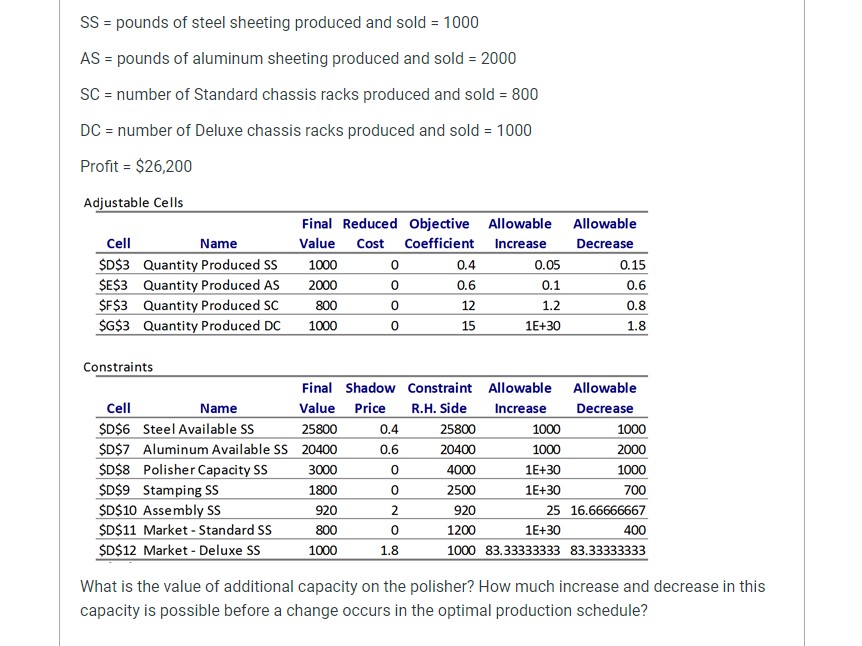

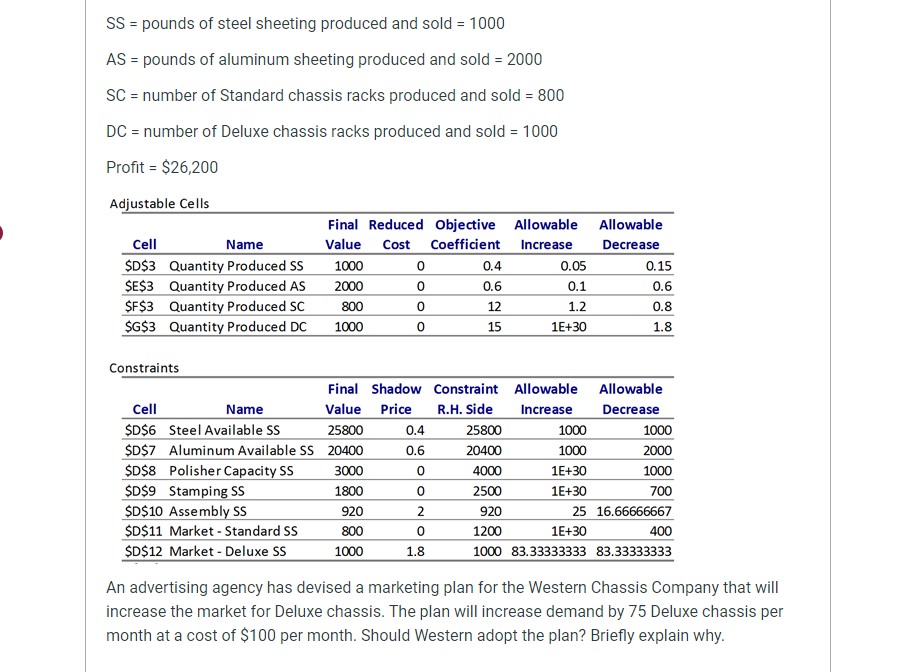

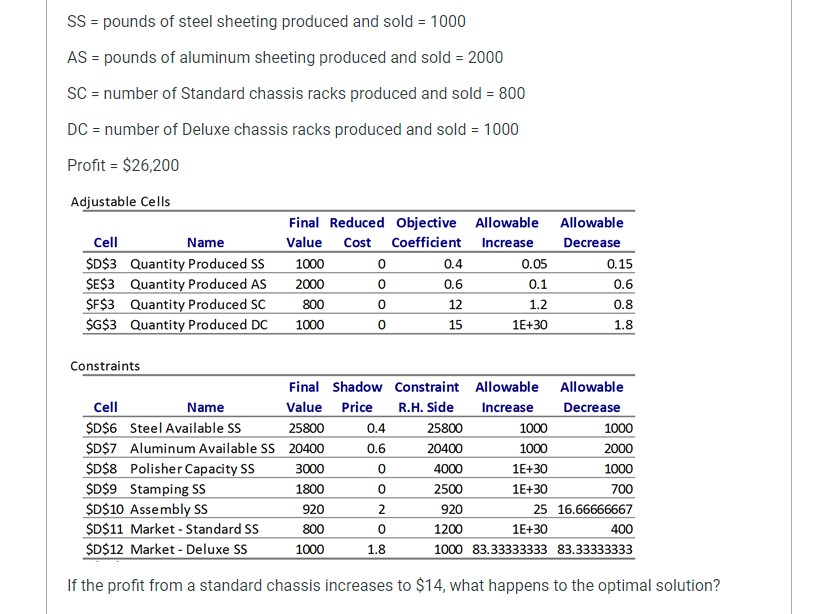

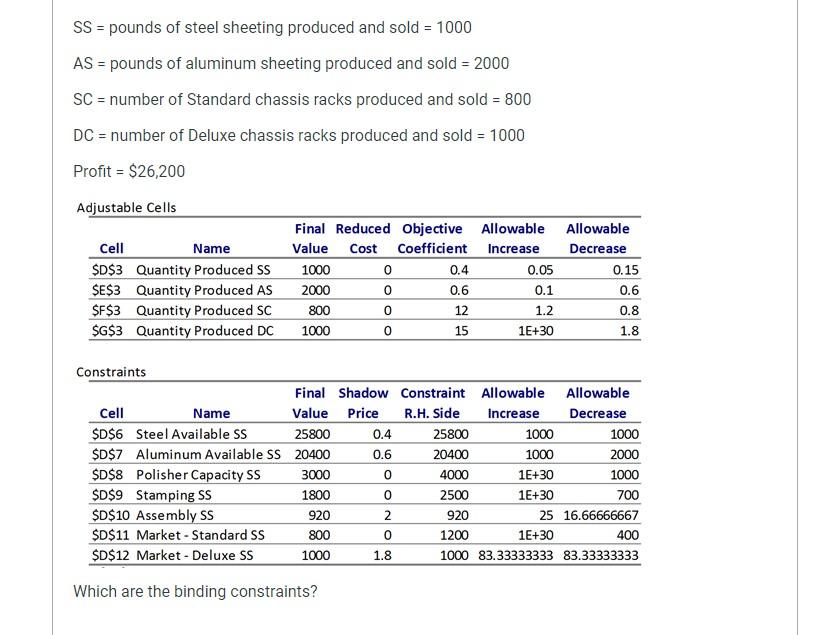

Western Chassis produces high-quality polished steel and aluminum sheeting and two lines of industrial chassis for the rack mounting of Internet routers, modems, and other telecommunications equipment. The contribution margin (contribution toward profit) for steel sheeting is $0.40 per pound and for aluminum sheeting is $0.60 per pound. Western earns $12 contribution on the sale of a Standard chassis rack and $15 contribution on a Deluxe chassis rack. During the next production cycle, Western can buy and use up to 25,800 pounds of raw unfinished steel either in sheeting or in chassis. Similarly, 20,400 pounds of aluminum are available. One standard chassis rack requires 16 pounds of steel and 8 pounds of aluminum. A Deluxe chassis rack requires 12 pounds of each metal. The output of metal sheeting is restricted only by the capacity of the polisher. For the next production cycle, the polisher can handle any mix of the two metals up to 4,000 pounds of metal sheeting. Chassis manufacture can be restricted by either metal stamping or assembly operations; no polishing is required. During the cycle no more than 2,500 total chassis can be stamped, and there will be 920 hours of assembly time available. The assembly time required is 24 minutes for the Standard chassis rack and 36 minutes for the Deluxe chassis rack. Finally, market conditions limit the number of Standard chassis racks sold to no more than 1,200 Standard and no more than 1,000 Deluxe. Any quantities of metal sheeting can be sold. The following is the optimal production plan and sensitivity report for the production planning problem. SS = pounds of steel sheeting produced and sold = 1000 AS = pounds of aluminum sheeting produced and sold = 2000 SC = number of Standard chassis racks produced and sold = 800 DC = number of Deluxe chassis racks produced and sold = 1000 Profit = $26,200 Adjustable Cells Cell Name $D$3 Quantity Produced SS $E$3 Quantity Produced AS $F$3 Quantity Produced SC $G$3 Quantity Produced DC Constraints Final Reduced Objective Allowable Value Cost Coefficient Increase 1000 2000 800 1000 0 Cell Name $D$6 Steel Available SS 25800 $D$7 Aluminum Available SS 20400 $D$8 Polisher Capacity SS 3000 $D$9 Stamping SS 1800 $D$10 Assembly SS 920 $D$11 Market - Standard SS 800 $D$12 Market - Deluxe SS 1000 0 0 0.4 0.6 12 15 0 2 0 1.8 0.05 0.1 1.2 1E+30 Final Shadow Constraint Value Price R.H. Side 0.4 0.6 25800 20400 0 4000 2500 920 1200 1000 83.33333333 83.33333333 Allowable Increase 1000 1000 1E+30 1E+30 Allowable Decrease 0.15 0.6 0.8 1.8 1E+30 Allowable Decrease 1000 2000 1000 700 25 16.66666667 400 What is the incremental contribution associated with adding an hour of assembly time? Over what range of increase is the marginal value valid? SS = pounds of steel sheeting produced and sold = 1000 AS = pounds of aluminum sheeting produced and sold = 2000 SC = number of Standard chassis racks produced and sold = 800 DC = number of Deluxe chassis racks produced and sold = 1000 Profit = $26,200 Adjustable Cells Cell Name $D$3 Quantity Produced SS $E$3 Quantity Produced AS $F$3 Quantity Produced SC $G$3 Quantity Produced DC Constraints Final Reduced Objective Allowable Value Cost Coefficient Increase $D$8 Polisher Capacity SS $D$9 Stamping SS $D$10 Assembly SS $D$11 Market - Standard SS $D$12 Market - Deluxe SS 1000 2000 800 1000 Cell Name $D$6 Steel Available SS $D$7 Aluminum Available SS 20400 3000 1800 920 800 1000 0 0 0 0 0 0 2 0.4 0.6 12 15 Final Shadow Constraint Value Price R.H. Side Increase 25800 0.4 25800 0.6 20400 4000 2500 920 1200 1000 83.33333333 83.33333333 0 1.8 0.05 0.1 1.2 1E+30 Allowable Decrease 1000 1000 1E+30 1E+30 0.15 0.6 0.8 1.8 Allowable Allowable Decrease 1E+30 1000 2000 1000 700 25 16.66666667 400 What is the value of additional capacity on the polisher? How much increase and decrease in this capacity is possible before a change occurs in the optimal production schedule? SS = pounds of steel sheeting produced and sold = 1000 AS = pounds of aluminum sheeting produced and sold = 2000 SC = number of Standard chassis racks produced and sold = 800 DC = number of Deluxe chassis racks produced and sold = 1000 Profit = $26,200 Adjustable Cells Cell Name $D$3 Quantity Produced SS $E$3 Quantity Produced AS $F$3 Quantity Produced SC $G$3 Quantity Produced DC Constraints Final Reduced Objective Allowable Value Cost Coefficient Increase 1000 2000 800 1000 0 0 0 0 Cell Name $D$6 Steel Available SS 25800 $D$7 Aluminum Available SS 20400 $D$8 Polisher Capacity SS 3000 $D$9 Stamping SS 1800 $D$10 Assembly SS 920 $D$11 Market - Standard SS 800 $D$12 Market - Deluxe SS 1000 0.4 0.6 0 0 2 0.4 0.6 12 15 Final Shadow Constraint Allowable Allowable Value Price R.H. Side Increase Decrease 0 1.8 0.05 0.1 1.2 1E+30 Allowable Decrease 1000 1000 1E+30 1E+30 0.15 0.6 0.8 1.8 25800 20400 4000 2500 920 1200 1000 83.33333333 83.33333333 1E+30 1000 2000 1000 700 25 16.66666667 400 An advertising agency has devised a marketing plan for the Western Chassis Company that will increase the market for Deluxe chassis. The plan will increase demand by 75 Deluxe chassis per month at a cost of $100 per month. Should Western adopt the plan? Briefly explain why. SS = pounds of steel sheeting produced and sold = 1000 AS = pounds of aluminum sheeting produced and sold = 2000 SC = number of Standard chassis racks produced and sold = 800 DC = number of Deluxe chassis racks produced and sold = 1000 Profit = $26,200 Adjustable Cells Cell Name $D$3 Quantity Produced SS $E$3 Quantity Produced AS $F$3 Quantity Produced SC $G$3 Quantity Produced DC Constraints Final Reduced Objective Allowable Value Cost Coefficient Increase 1000 2000 800 1000 0 0 0 0 0.4 0.6 12 15 0 0.05 0.1 1.2 1E+30 0 2 0 1.8 Allowable Increase Final Shadow Constraint Value Price R.H. Side 25800 0.4 25800 0.6 20400 4000 2500 920 1200 1000 83.33333333 83.33333333 Allowable Decrease 1000 1000 1E+30 1E+30 0.15 0.6 Cell Name $D$6 Steel Available SS $D$7 Aluminum Available SS 20400 $D$8 Polisher Capacity SS 3000 $D$9 Stamping SS 1800 $D$10 Assembly Ss 920 $D$11 Market - Standard SS 800 $D$12 Market - Deluxe SS 1000 If the profit from a standard chassis increases to $14, what happens to the optimal solution? 0.8 1.8 1E+30 Allowable Decrease 1000 2000 1000 700 25 16.66666667 400 SS = pounds of steel sheeting produced and sold = 1000 AS = pounds of aluminum sheeting produced and sold = 2000 SC = number of Standard chassis racks produced and sold = 800 DC = number of Deluxe chassis racks produced and sold = 1000 Profit = $26,200 Adjustable Cells Cell Name $D$3 Quantity Produced SS $E$3 Quantity Produced AS $F$3 Quantity Produced SC $G$3 Quantity Produced DC Constraints Final Reduced Objective Allowable Value Cost Coefficient Increase 1000 2000 800 1000 0 0 0 Cell Name $D$6 Steel Available SS 25800 $D$7 Aluminum Available SS 20400 $D$8 Polisher Capacity SS 3000 $D$9 Stamping SS 1800 $D$10 Assembly SS 920 $D$11 Market - Standard SS 800 $D$12 Market - Deluxe SS 1000 Which are the binding constraints? 0 Final Shadow Constraint Allowable Value Price R.H. Side Increase 0.4 0.6 0 0.4 0.6 12 15 0 2 0 1.8 0.05 0.1 1.2 1E+30 1000 1000 1E+30 1E+30 Allowable Decrease 0.15 0.6 0.8 1.8 1E+30 Allowable Decrease 25800 20400 4000 2500 920 1200 1000 83.33333333 83.33333333 1000 2000 1000 700 25 16.66666667 400

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started