what does that mean?

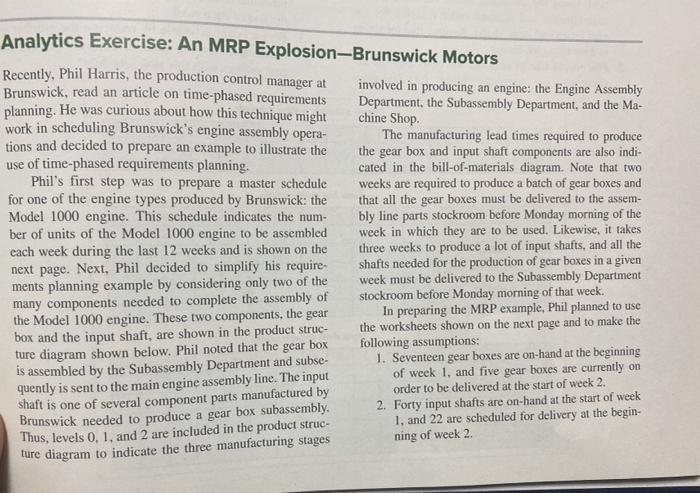

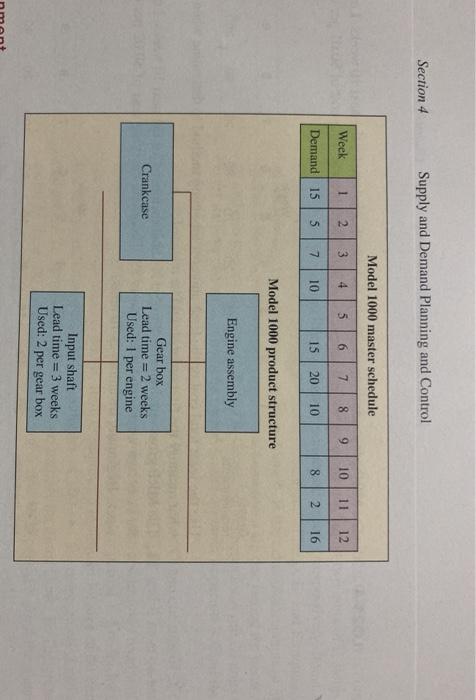

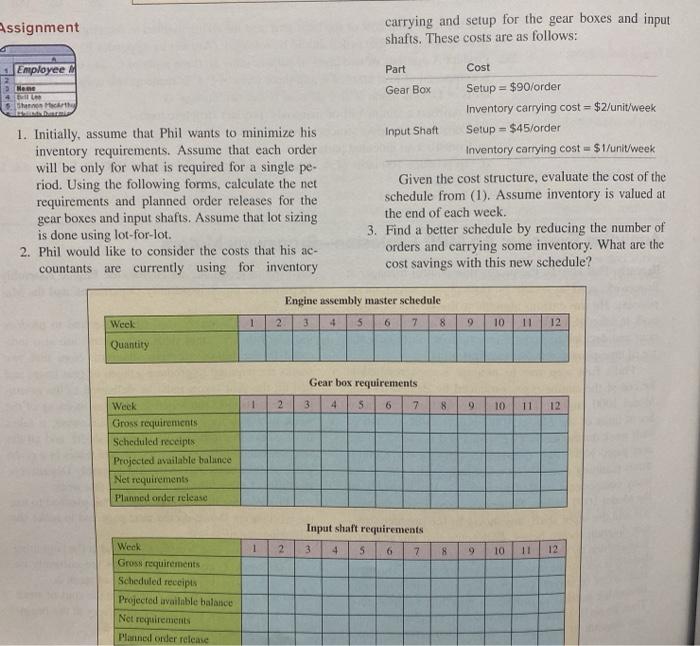

Analytics Exercise: An MRP Explosion-Brunswick Motors Recently, Phil Harris, the production control manager at Brunswick, read an article on time-phased requirements involved in producing an engine: the Engine Assembly planning. He was curious about how this technique might Department, the Subassembly Department, and the Ma. work in scheduling Brunswick's engine assembly opera- chine Shop tions and decided to prepare an example to illustrate the The manufacturing lead times required to produce use of time-phased requirements planning. the gear box and input shaft components are also indi- cated in the bill-of-materials diagram. Note that two Phil's first step was to prepare a master schedule weeks are required to produce a batch of gear boxes and for one of the engine types produced by Brunswick: the that all the gear boxes must be delivered to the assem- Model 1000 engine. This schedule indicates the num- bly line parts stockroom before Monday morning of the ber of units of the Model 1000 engine to be assembled week in which they are to be used. Likewise, it takes each week during the last 12 weeks and is shown on the three weeks to produce a lot of input shafts, and all the next page. Next, Phil decided to simplify his require shafts needed for the production of gear boxes in a given ments planning example by considering only two of the week must be delivered to the Subassembly Department many components needed to complete the assembly of stockroom before Monday morning of that week. the Model 1000 engine. These two components, the gear In preparing the MRP example, Phil planned to use box and the input shaft, are shown in the product struc- the worksheets shown on the next page and to make the ture diagram shown below. Phil noted that the gear box following assumptions: is assembled by the Subassembly Department and subse- 1. Seventeen gear boxes are on-hand at the beginning of week 1, and five gear boxes are currently on quently is sent to the main engine assembly line. The input order to be delivered at the start of week 2. shaft is one of several component parts manufactured by 2. Forty input shafts are on-hand at the start of week Brunswick needed to produce a gear box subassembly. 1, and 22 are scheduled for delivery at the begin- Thus, levels 0, 1, and 2 are included in the product struc- ning of week 2 ture diagram to indicate the three manufacturing stages Section 4 Supply and Demand Planning and Control Model 1000 master schedule Week 1 2 3 4 5 6 7 8 9 10 11 12 Demand 15 5 10 15 20 10 8 2 16 Model 1000 product structure Engine assembly Crankcase Gear box Lead time = 2 weeks Used: 1 per engine Input shaft Lead time = 3 weeks Used: 2 per gear box Assignment carrying and setup for the gear boxes and input shafts. These costs are as follows: Employee Dil Share the 1. Initially, assume that Phil wants to minimize his inventory requirements. Assume that each order will be only for what is required for a single pe- riod. Using the following forms, calculate the net requirements and planned order releases for the gear boxes and input shafts. Assume that lot sizing is done using lot-for-lot. 2. Phil would like to consider the costs that his ac- countants are currently using for inventory Part Cost Gear Box Setup = $90/order Inventory carrying cost = $2/unit/week Input Shaft Setup = $45/order Inventory carrying cost = $1/unit/week Given the cost structure, evaluate the cost of the schedule from (1). Assume inventory is valued at the end of each week. 3. Find a better schedule by reducing the number of orders and carrying some inventory. What are the cost savings with this new schedule? Engine assembly master schedule 2 3 + 5 6 7 8 Week 1 9 10 11 12 Quantity Gear box requirements 1 2 3 4 5 6 7 8 10 12 Week Gross requirements Scheduled receipts Projected available balance Net requirements Planned order release Input shaft requirements 3 4 5 6 7 1 2 8 9 10 12 Week Gross requirements Scheduled receipts Projected available balance Net requirements Plained order release Download the blank xls below, and try to complete the MRP details according to the case. For question 3, regarding Least Total Cost lot sizing, the trick is to experiment with different order sizes. Without this consideration, MRP will simply order exactly what quantity is needed to fulfill net requirements, for a given time bucket. However, if you consider the cost of placing an order, and the cost of carrying inventory, it may be less expensive to order a larger quantity (if inventory carrying is not too expensive) or it may be better to order more often with smaller order sizes, if inventory carrying is too expensive. Attach your xls. Analytics Exercise: An MRP Explosion-Brunswick Motors Recently, Phil Harris, the production control manager at Brunswick, read an article on time-phased requirements involved in producing an engine: the Engine Assembly planning. He was curious about how this technique might Department, the Subassembly Department, and the Ma. work in scheduling Brunswick's engine assembly opera- chine Shop tions and decided to prepare an example to illustrate the The manufacturing lead times required to produce use of time-phased requirements planning. the gear box and input shaft components are also indi- cated in the bill-of-materials diagram. Note that two Phil's first step was to prepare a master schedule weeks are required to produce a batch of gear boxes and for one of the engine types produced by Brunswick: the that all the gear boxes must be delivered to the assem- Model 1000 engine. This schedule indicates the num- bly line parts stockroom before Monday morning of the ber of units of the Model 1000 engine to be assembled week in which they are to be used. Likewise, it takes each week during the last 12 weeks and is shown on the three weeks to produce a lot of input shafts, and all the next page. Next, Phil decided to simplify his require shafts needed for the production of gear boxes in a given ments planning example by considering only two of the week must be delivered to the Subassembly Department many components needed to complete the assembly of stockroom before Monday morning of that week. the Model 1000 engine. These two components, the gear In preparing the MRP example, Phil planned to use box and the input shaft, are shown in the product struc- the worksheets shown on the next page and to make the ture diagram shown below. Phil noted that the gear box following assumptions: is assembled by the Subassembly Department and subse- 1. Seventeen gear boxes are on-hand at the beginning of week 1, and five gear boxes are currently on quently is sent to the main engine assembly line. The input order to be delivered at the start of week 2. shaft is one of several component parts manufactured by 2. Forty input shafts are on-hand at the start of week Brunswick needed to produce a gear box subassembly. 1, and 22 are scheduled for delivery at the begin- Thus, levels 0, 1, and 2 are included in the product struc- ning of week 2 ture diagram to indicate the three manufacturing stages Section 4 Supply and Demand Planning and Control Model 1000 master schedule Week 1 2 3 4 5 6 7 8 9 10 11 12 Demand 15 5 10 15 20 10 8 2 16 Model 1000 product structure Engine assembly Crankcase Gear box Lead time = 2 weeks Used: 1 per engine Input shaft Lead time = 3 weeks Used: 2 per gear box Assignment carrying and setup for the gear boxes and input shafts. These costs are as follows: Employee Dil Share the 1. Initially, assume that Phil wants to minimize his inventory requirements. Assume that each order will be only for what is required for a single pe- riod. Using the following forms, calculate the net requirements and planned order releases for the gear boxes and input shafts. Assume that lot sizing is done using lot-for-lot. 2. Phil would like to consider the costs that his ac- countants are currently using for inventory Part Cost Gear Box Setup = $90/order Inventory carrying cost = $2/unit/week Input Shaft Setup = $45/order Inventory carrying cost = $1/unit/week Given the cost structure, evaluate the cost of the schedule from (1). Assume inventory is valued at the end of each week. 3. Find a better schedule by reducing the number of orders and carrying some inventory. What are the cost savings with this new schedule? Engine assembly master schedule 2 3 + 5 6 7 8 Week 1 9 10 11 12 Quantity Gear box requirements 1 2 3 4 5 6 7 8 10 12 Week Gross requirements Scheduled receipts Projected available balance Net requirements Planned order release Input shaft requirements 3 4 5 6 7 1 2 8 9 10 12 Week Gross requirements Scheduled receipts Projected available balance Net requirements Plained order release Download the blank xls below, and try to complete the MRP details according to the case. For question 3, regarding Least Total Cost lot sizing, the trick is to experiment with different order sizes. Without this consideration, MRP will simply order exactly what quantity is needed to fulfill net requirements, for a given time bucket. However, if you consider the cost of placing an order, and the cost of carrying inventory, it may be less expensive to order a larger quantity (if inventory carrying is not too expensive) or it may be better to order more often with smaller order sizes, if inventory carrying is too expensive. Attach your xls