Answered step by step

Verified Expert Solution

Question

1 Approved Answer

What is the capacity of Station B in watches per hour? Group of answer choices 4 8 watches / hour 3 0 watch / hour

What is the capacity of Station B in watches per hour?

Group of answer choices

watcheshour

watchhour

watcheshour

watcheshour

Which is the bottleneck step for this process?

Group of answer choices

Station A

Station C

Station E

Station B

Station F

Station D

Suppose the process was redesigned to operate as a machinepaced line. In other words, the inventory buffer areas between stations were removed and a conveyor belt was installed to move items between workers at the bottleneck rate. Which of process analysis measures as we have been computing them so far in the course would likely change as a result compared with the prior workerpaced line Check all that apply.

Group of answer choices

Cycle Time

Throughput Time

Throughput Rate

None of these options

WIP Level

Now suppose that the process was redesigned to operate as independent worker cells. In this design, each worker handles all the tasks for a given watch. What would be the process capacity of this cellular design in watches per hour? Hint: This will require you to first compute capacity for one worker cell and then multiple that capacity by since there will be cells working in parallel.

Group of answer choices

watcheshour

watcheshour

watcheshour

watcheshour

Given your expertise in analyzing watch production processes, another watch manufacturer has asked you to evaluate the throughput time in their highend custom manufacturing process. They do not want to provide details on all of their process steps due to confidentiality issues but are willing to share that the average throughput rate of their process is watcheshour and that the average workinprocess inventory level is watches. Based on this information, what is your best estimate of their average throughput time?

Group of answer choices

hour

minutes

minutes

hours

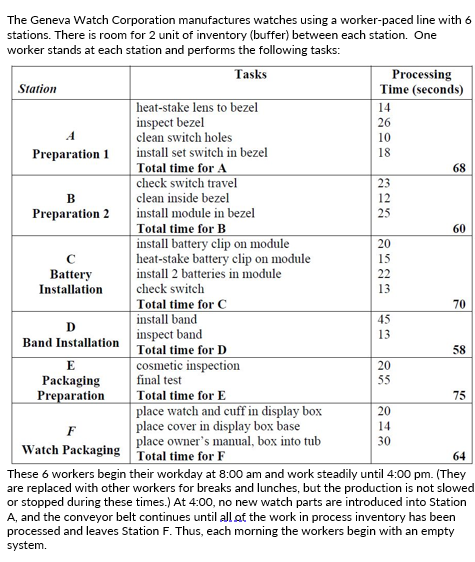

hoursThe Geneva Watch Corporation manufactures watches using a workerpaced line with

stations. There is room for unit of inventory buffer between each station. One

worker stands at each station and performs the following tasks:

These workers begin their workday at : am and work steadily until : pmThey

are replaced with other workers for breaks and lunches, but the production is not slowed

or stopped during these times. At : no new watch parts are introduced into Station

and the conveyor belt continues until all af the work in process inventory has been

processed and leaves Station F Thus, each morning the workers begin with an empty

system.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started