Question: What new knowledge/skills have you learned from Planned Approach or Methodology, Logistics Option Analysis, Evaluate Results, Develop Implementation Plan, Logistics Relationship With Other Corporate Functions,

What new knowledge/skills have you learned from Planned Approach or Methodology, Logistics Option Analysis, Evaluate Results, Develop Implementation Plan, Logistics Relationship With Other Corporate Functions, and Role of the Logistics or Distribution Manager, and how will you apply the new skills or knowledge?

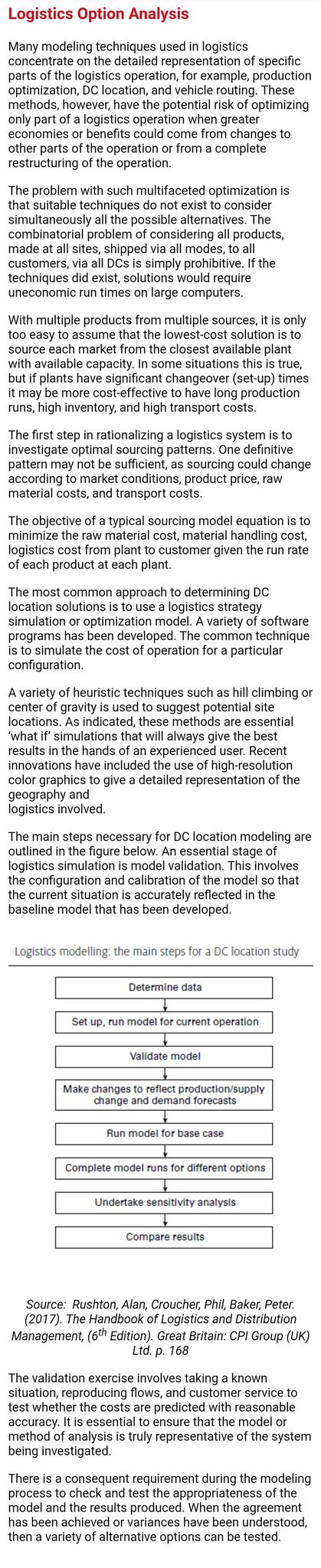

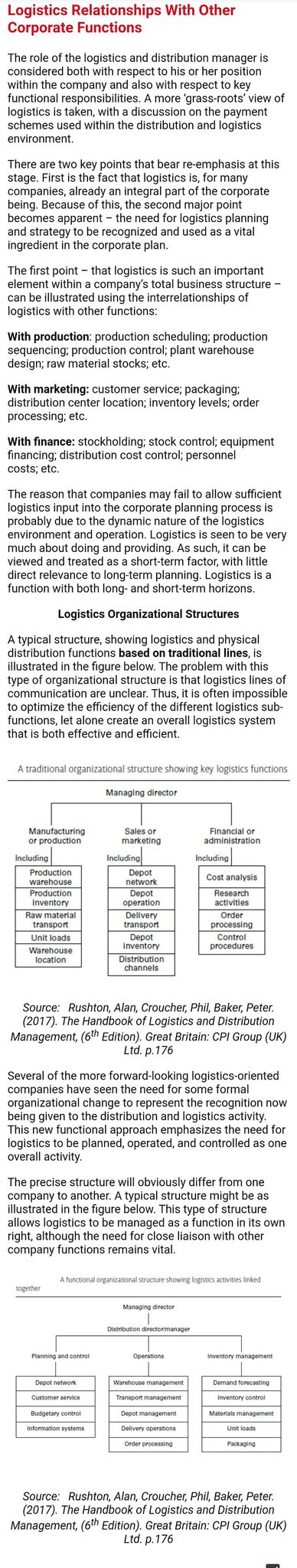

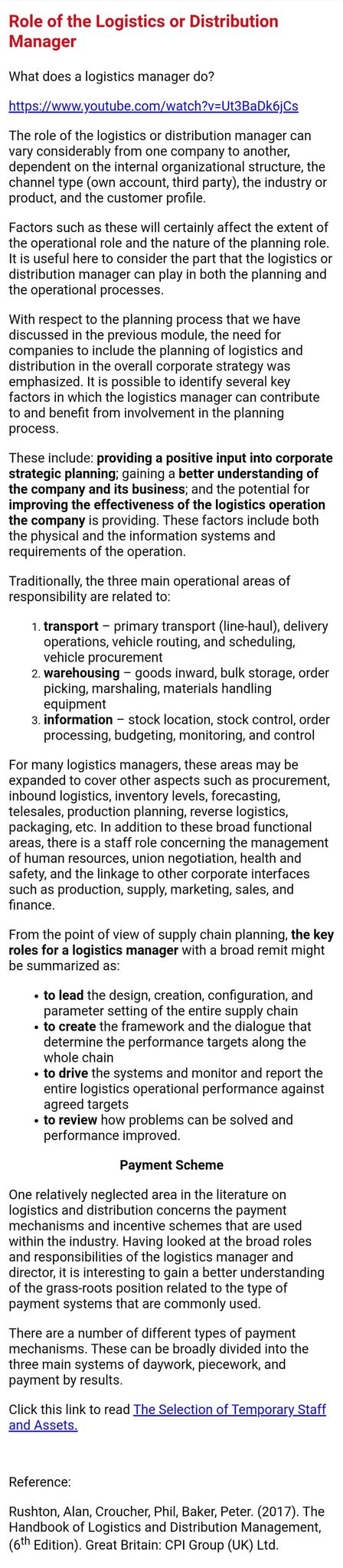

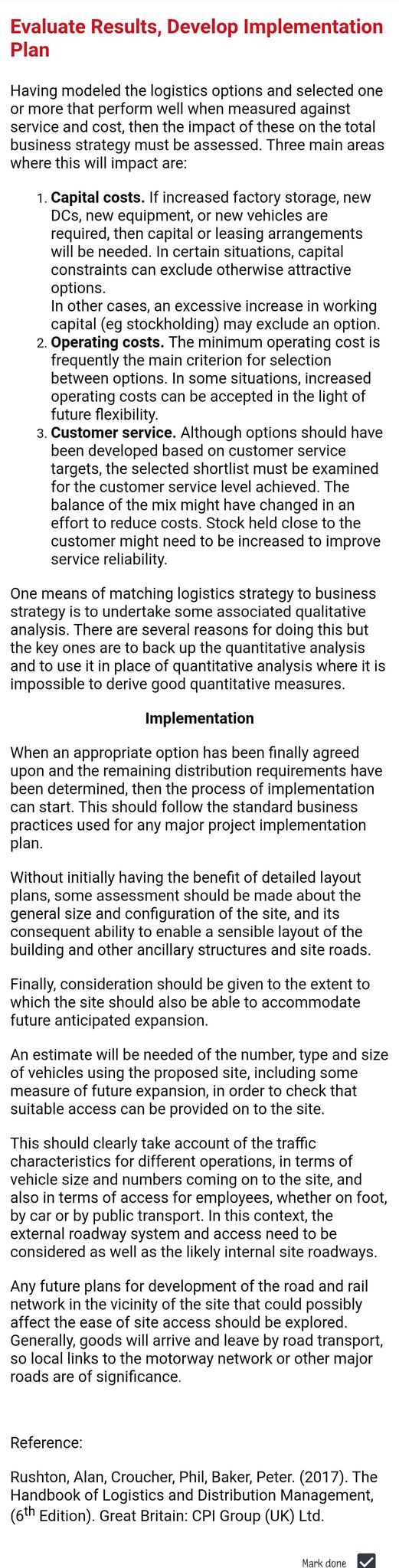

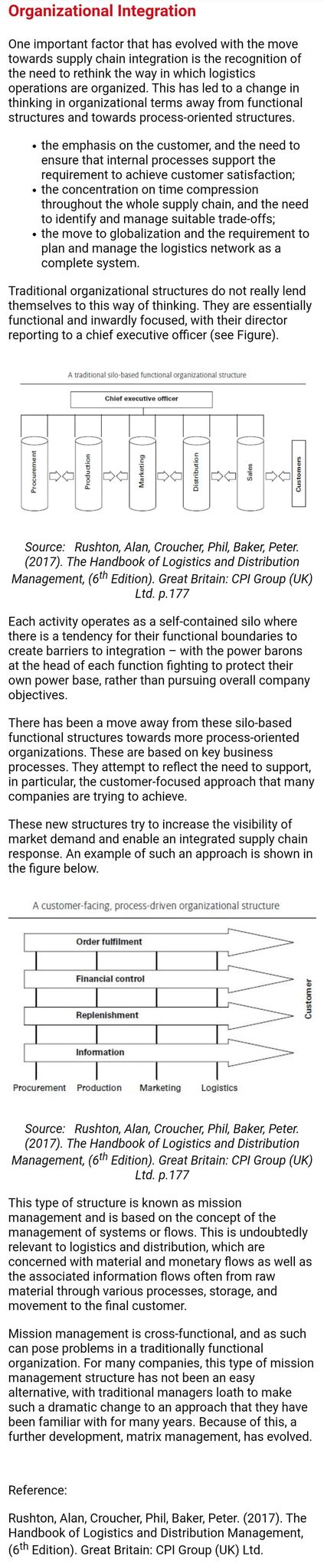

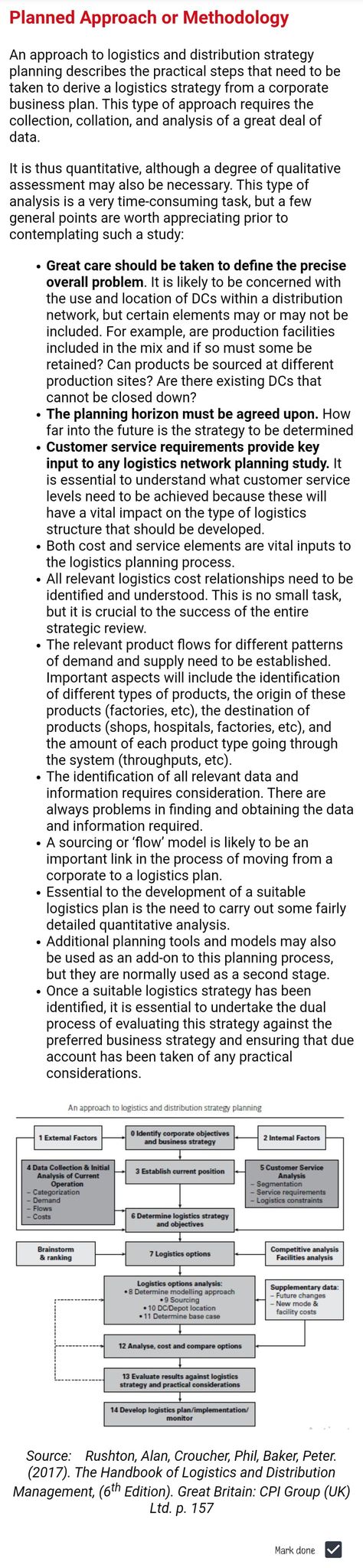

Logistics Option Analysis Many modeling techniques used in logistics concentrate on the detailed representation of specific parts of the logistics operation, for example, production optimization, DC location, and vehicle routing. These methods, however, have the potential risk of optimizing only part of a logistics operation when greater economies or benefits could come from changes to other parts of the operation or from a complete restructuring of the operation. The problem with such multifaceted optimization is that suitable techniques do not exist to consider simultaneously all the possible alternatives. The combinatorial problem of considering all products, made at all sites, shipped via all modes, to all customers, via all DCs is simply prohibitive. If the techniques did exist, solutions would require uneconomic run times on large computers. With multiple products from multiple sources, it is only too easy to assume that the lowest-cost solution is to source each market from the closest available plant with available capacity. In some situations this is true, but if plants have significant changeover (set-up) times it may be more cost-effective to have long production runs, high inventory, and high transport costs. The first step in rationalizing a logistics system is to investigate optimal sourcing patterns. One definitive pattern may not be sufficient, as sourcing could change according to market conditions, product price, raw material costs, and transport costs. The objective of a typical sourcing model equation is to minimize the raw material cost, material handling cost logistics cost from plant to customer given the run rate of each product at each plant. The most common approach to determining DC ocation solutions is to use a logistics strategy simulation or optimization model. A variety of software programs has been developed. The common technique s to simulate the cost of operation for a particular configuration. A variety of heuristic techniques such as hill climbing or center of gravity is used to suggest potential site locations. As indicated, these methods are essential 'what if simulations that will always give the best results in the hands of an experienced user. Recent Innovations have included the use of high-resolution color graphics to give a detailed representation of the geography and logistics involved. The main steps necessary for DC location modeling are outlined in the figure below. An essential stage of logistics simulation is model validation. This involves the configuration and calibration of the model so that the current situation is accurately reflected in the baseline model that has been developed. Logistics modelling: the main steps for a DC location study Determine data Set up, run model for current operation Validate model Make changes to reflect production/supply change and demand forecasts Run model for base case Complete model runs for different options Undertake sensitivity analysis Compare results Source: Rushton, Alan, Croucher, Phil, Baker, Peter. (2017). The Handbook of Logistics and Distribution Management, (6th Edition). Great Britain: CPI Group (UK) Ltd. p. 168 The validation exercise involves taking a known situation, reproducing flows, and customer service to test whether the costs are predicted with reasonable accuracy. It is essential to ensure that the model or method of analysis is truly representative of the system being investigated. There is a consequent requirement during the modeling process to check and test the appropriateness of the model and the results produced. When the agreement has been achieved or variances have been understood, then a variety of alternative options can be tested.Logistics Relationships With Other Corporate Functions The role of the logistics and distribution manager is considered both with respect to his or her position within the company and also with respect to key functional responsibilities. A more 'grass-roots' view of logistics is taken, with a discussion on the payment schemes used within the distribution and logistics environment. There are two key points that bear re-emphasis at this stage. First is the fact that logistics is, for many companies, already an integral part of the corporate being. Because of this, the second major point becomes apparent - the need for logistics planning and strategy to be recognized and used as a vital ingredient in the corporate plan. The first point - that logistics is such an important element within a company's total business structure - can be illustrated using the interrelationships of logistics with other functions: With production: production scheduling; production sequencing; production control; plant warehouse design; raw material stocks; etc. With marketing: customer service; packaging; distribution center location; inventory levels; order processing; etc. With finance: stockholding; stock control; equipment financing; distribution cost control; personnel costs; etc. The reason that companies may fail to allow sufficient logistics input into the corporate planning process is probably due to the dynamic nature of the logistics environment and operation. Logistics is seen to be very much about doing and providing. As such, it can be viewed and treated as a short-term factor, with little direct relevance to long-term planning. Logistics is a function with both long- and short-term horizons. Logistics Organizational Structures A typical structure, showing logistics and physical distribution functions based on traditional lines, is illustrated in the figure below. The problem with this type of organizational structure is that logistics lines of communication are unclear. Thus, it is often impossible to optimize the efficiency of the different logistics sub- functions, let alone create an overall logistics system that is both effective and efficient. A traditional organizational structure showing key logistics functions Managing director Manufacturing Sales or Financial or or production marketing administration Including Including Including Production Depot warehouse network Cost analysis Production Depot Research inventory operation activities Raw material Delivery Order transport ransport processing Unit loads Depot Control Warehouse Inventory procedures location Distribution channels Source: Rushton, Alan, Croucher, Phil, Baker, Peter. (2017). The Handbook of Logistics and Distribution Management, (6th Edition). Great Britain: CPI Group (UK) Lid. p. 176 Several of the more forward-looking logistics-oriented companies have seen the need for some formal organizational change to represent the recognition now being given to the distribution and logistics activity. This new functional approach emphasizes the need for logistics to be planned, operated, and controlled as one overall activity. The precise structure will obviously differ from one company to another. A typical structure might be as illustrated in the figure below. This type of structure allows logistics to be managed as a function in its own right, although the need for close liaison with other company functions remains vital. A functional organizational structure showing logistics activities linked together Managing director Distribution directorimanager Planning and control Inventory ma Depot network Warehouse management Demand forecasting Customer service Transport management Inventory control Budgetary control Depot management Materials management Information systems Delivery operations Unit loads Order processing Packaging Source: Rushton, Alan, Croucher, Phil, Baker, Peter. (2017). The Handbook of Logistics and Distribution Management, (6th Edition). Great Britain: CPI Group (UK) Ltd. p. 176Role of the Logistics or Distribution Manager What does a logistics manager do? WWVMWWM The role of the logistics or distribution manager can vary considerably from one company to another. dependent on the internal organizational structure. the channel type (own account, third party), the industry or product. and the customer prole. Factors such as these will certainly affect the extent of the operational role and the nature of the planning role. It is usefui here to consider the part that the logistics or distribution manager can play In both the planning and the operational processes. With respect to the planning process that we have discussed in the previous module. the need for companies to include the planning of iogistics and distribution In the overall corporate strategy was emphasized. It is possible to identify several key factors in which the logistics manager can contribute to and benet from involvement In the planning process. These Include: providing a positive input into corporate strategic planning; gaining a better understanding of the company and its business; and the potential for improving the effectiveness of the logistics operation the company is providing. These factors include both the physical and the information systems and requirements of the operation. Traditionally. the three main operational areas of responsibility are related to; 1. transport - primarytransport (line-haul). delivery operations, vehicle routing. and scheduling, vehicle procurement 2. warehousing - goods inward, bulk storage, order picking. marshallng, materials handling equipment 3. infant-ration - stock location, stock control. order processing, budgeting. monitoring. and control For many logistics managers. these areas may be expanded to cover other aspects such as procurement, inbound logistics. inventory levels. forecasting, telesales. production planning. reverse logistics. packaging, etc. In addition to these broad functlonai areas. there is a staff role concerning the management of human resources. union negotiation. health and safety. and the linkage to other corporate interfaces such as production. supply. marketing. sales, and nance. From the point of View of supply chain pianning. the key roles for a logistics manager with a broad remit might be summarized as: - to lead the design. creation. conguration. and parameter setting of the entire supply chain - to create the framework and the dialogue that determine the performance targets along the whole chain - to drive the systems and monitor and report the entire logistics operational performance against agreed targets u to review how problems can be solved and performance Improved. Payment Scheme One relatively neglected area In the literature on logistics and distribution concerns the payment mechanisms and incentive schemes that are used within the industry. Having looked at the broad roles and responsibilities ofthe iogistics manager and director. it Is interesting to gain a better understanding of the grass-roots position related to the type of payment systems that are commonly used. There are a number of different types of payment mechanisms. These can be broadly divided into the three main systems of daywork, piecework. and payment by results. Click this link to read The Selection of Temporary Staff Meets. Reference: Rushton, Alan, Croucher. Phil. Baker. Peter. (2017). The Handbook of Logistics and Distribution Management. (6"1 Edition). Great Britain: CPI Group (UK) Ltd. Evaluate Results, Develop Implementation Plan Having modeled the logistics options and selected one or more that perform well when measured against service and cost, then the impact of these on the total business strategy must be assessed. Three main areas where this will impact are: 1. Capital costs. If increased factory storage, new DCs. new equipment. or new vehicles are required, then capital or leasing arrangements will be needed. In certain situations, capital constraints can exclude otherwise attractive options. In other cases. an excessive increase in working capital (eg stockholding) may exclude an option. 2. Operating costs. The minimum operating cost Is frequently the main criterion for selection between options. In some situations, increased operating costs can be accepted in the light of future exibility. 3. Customer service. Although options should have been developed based on customer service targets, the selected shortlist must be examined for the customer service level achieved. The balance of the mix might have changed in an effort to reduce costs. Stock held close to the customer might need to be increased to improve service reliability. One means of matching logistics strategy to business strategy Is to undertake some associated qualitative analysis. There are several reasons for doing this but the key ones are to back up the quantitative analysis and to use it in piece of quantitative analysis where it is impossible to derive good quantitative measures. Implementation When an appropriate option has been nally agreed upon and the remaining distribution requirements have been determined. then the process of implementation can start. This should follow the standard business practices used for any major project implementation plan. Without initially having the benet of detailed layout plans, some assessment should be made about the general size and conguration of the site. and its consequent ability to enable a sensible layout of the building and other ancillary structures and site roads. Finally, consideration should be given to the extent to which the site should also be able to accommodate future anticipated expansion. An estimate will be needed of the number. type and size of vehicles using the proposed site, including some measure of future expansion. in order to check that suitable access can be provided on to the site. This should clearly take account of the trafc characteristics for different operations, in terms of vehicle size and numbers coming on to the site. and also in terms of access for employees. whether on foot, by car or by public transport. In this context. the external roadway system and access need to be considered as Well as the likely internal site roadways. Any future plans for development of the road and rail network in the vicinity of the site that could possibly affect the ease of site access should be explored. Generally. goods will arrive and leave by road transport. so local links to the motorway network or other major roads are of signicance. Reference: Rushton, Alan, Croucher, Phil, Baker, Peter. (2017). The Handbook of Logistics and Distribution Management, (61\" Edition). Great Britain: CPI Group (UK) Ltd. Markdone Organizational Integration One important factor that has evolved with the move towards supply chain integration is the recognition of the need to rethink the way in which logistics operations are organized. This has led to a change in thinking in organizational terms away from functional structures and towards process-oriented structures. . the emphasis on the customer, and the need to ensure that internal processes support the requirement to achieve customer satisfaction; . the concentration on time compression throughout the whole supply chain, and the need to identify and manage suitable trade-offs; . the move to globalization and the requirement to plan and manage the logistics network as a complete system. Traditional organizational structures do not really lend themselves to this way of thinking. They are essentially functional and inwardly focused, with their director reporting to a chief executive officer (see Figure). A traditional silo-based functional organizational structure Chief executive officer Marketing Production Distribution Procurement Sales Customers Source: Rushton, Alan, Croucher, Phil, Baker, Peter. (2017). The Handbook of Logistics and Distribution Management, (6th Edition). Great Britain: CPI Group (UK) Ltd. p. 177 Each activity operates as a self-contained silo where there is a tendency for their functional boundaries to create barriers to integration - with the power barons at the head of each function fighting to protect their own power base, rather than pursuing overall company objectives. There has been a move away from these silo-based functional structures towards more process-oriented organizations. These are based on key business processes. They attempt to reflect the need to support, in particular, the customer-focused approach that many companies are trying to achieve. These new structures try to increase the visibility of market demand and enable an integrated supply chain esponse. An example of such an approach is shown in the figure below. A customer-facing, process-driven organizational structure Order fulfilment Financial control Customer Replenishment Information Procurement Production Marketing Logistics Source: Rushton, Alan, Croucher, Phil, Baker, Peter. (2017). The Handbook of Logistics and Distribution Management, (6th Edition). Great Britain: CPI Group (UK) Ltd. p. 177 This type of structure is known as mission management and is based on the concept of the management of systems or flows. This is undoubtedly relevant to logistics and distribution, which are concerned with material and monetary flows as well as the associated information flows often from raw material through various processes, storage, and movement to the final customer. Mission management is cross-functional, and as such can pose problems in a traditionally functional organization. For many companies, this type of mission management structure has not been an easy alternative, with traditional managers loath to make such a dramatic change to an approach that they have been familiar with for many years. Because of this, a further development, matrix management, has evolved. Reference: Rushton, Alan, Croucher, Phil, Baker, Peter. (2017). The Handbook of Logistics and Distribution Management, (6th Edition). Great Britain: CPI Group (UK) Ltd.Planned Approach or Methodology An approach to logistics and distribution strategy planning describes the practical steps that need to be taken to derive a logistics strategy from a corporate business plan. This type of approach requires the collection, collation, and analysis of a great deal of data. It is thus quantitative, although a degree of qualitative assessment may also be necessary. This type of analysis is a very time-consuming task, but a few general points are worth appreciating prior to contemplating such a study: . Great care should be taken to define the precise overall problem. It is likely to be concerned with the use and location of DCs within a distribution network, but certain elements may or may not be included. For example, are production facilities included in the mix and if so must some be retained? Can products be sourced at different production sites? Are there existing DCs that cannot be closed down? . The planning horizon must be agreed upon. How far into the future is the strategy to be determined . Customer service requirements provide key input to any logistics network planning study. It is essential to understand what customer service levels need to be achieved because these will have a vital impact on the type of logistics structure that should be developed. . Both cost and service elements are vital inputs to the logistics planning process. . All relevant logistics cost relationships need to be identified and understood. This is no small task, but it is crucial to the success of the entire strategic review. . The relevant product flows for different patterns of demand and supply need to be established. Important aspects will include the identification of different types of products, the origin of these products (factories, etc), the destination of products (shops, hospitals, factories, etc), and the amount of each product type going through the system (throughputs, etc). . The identification of all relevant data and information requires consideration. There are always problems in finding and obtaining the data and information required. A sourcing or 'flow model is likely to be an important link in the process of moving from a corporate to a logistics plan. . Essential to the development of a suitable logistics plan is the need to carry out some fairly detailed quantitative analysis. Additional planning tools and models may also be used as an add-on to this planning process, but they are normally used as a second stage. . Once a suitable logistics strategy has been identified, it is essential to undertake the dual process of evaluating this strategy against the preferred business strategy and ensuring that due account has been taken of any practical considerations. An approach to logistics and distribution strategy planning 1 External Factors 0 Identify corporate objectives nd business strategy 2 Internal Factors 4 Data Collection & Initial 3 Establish current position 5 Customer Servi Analysis of Current Analysis Operation Segmentation Categorization - Service requirements - Demand - Logistics constraints 6 Determine logistics strategy and objectives Brainstorm & ranking 7 Logistics options mpetitive analysi Facilities analysis Logistics options analysis: . 8 Determine modelling approach upplementary data: .9 Sourcing -Future changes . 10 DC/Depot location -New mode & 11 Determine base case facility costs 12 Analyse, cost and compare options 13 Evaluate results against logistics strategy and practical considerations 14 Develop logistics plan/implementation/ Source: Rushton, Alan, Croucher, Phil, Baker, Peter. (2017). The Handbook of Logistics and Distribution Management, (6th Edition). Great Britain: CPI Group (UK) Ltd. p. 157 Mark done

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts