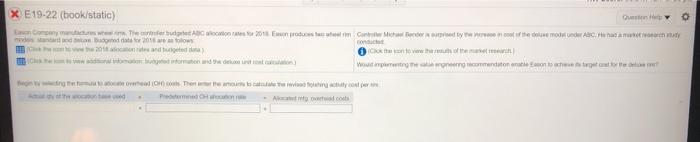

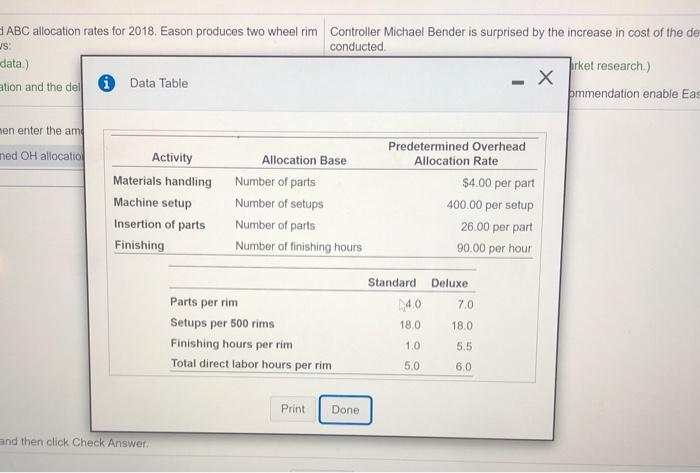

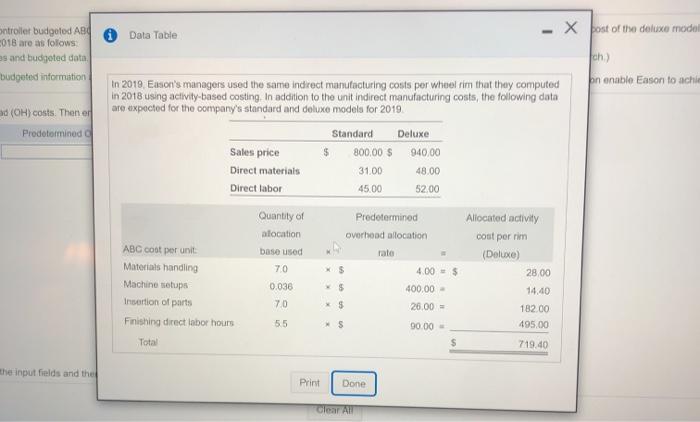

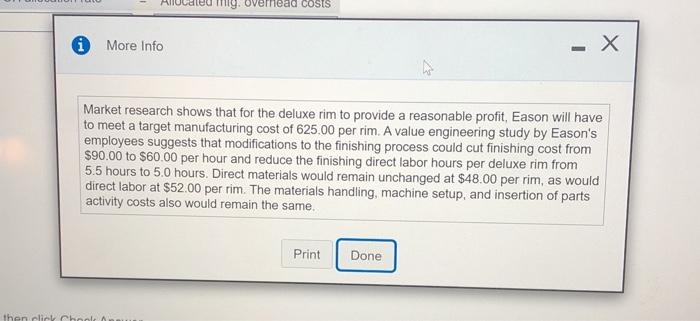

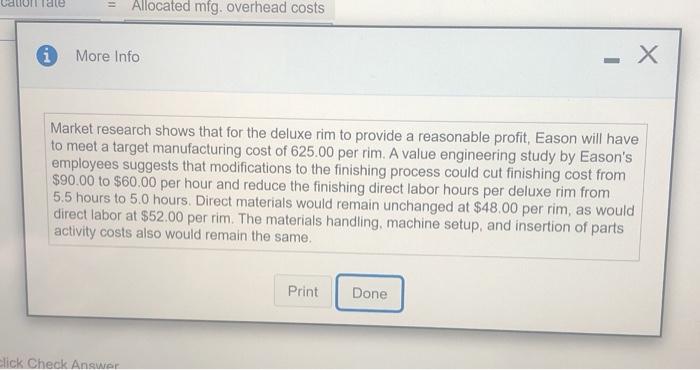

X 19-22 (book/static) Canonywhere in 2011 mayroll the model onder de become 2018 How More commandation to start - Acco JS ABC allocation rates for 2018. Eason produces two wheel rim Controller Michael Bender is surprised by the increase in cost of the de conducted data.) arket research.) - X mmendation enable Eas ation and the del Data Table nen enter the am med OH allocatio Activity Materials handling Machine setup Insertion of parts Finishing Allocation Base Number of parts Number of setups Number of parts Number of finishing hours Predetermined Overhead Allocation Rate $4.00 per part 400.00 per setup 26.00 per part 90.00 per hour Standard 40 18.0 Deluxe 7.0 18.0 Parts per rim Setups per 500 rims Finishing hours per rim Total direct labor hours per rim 1.0 5.5 5.0 6.0 Print Done and then click Check Answer X post of the deluxe model Data Table stroller budgolod ABC 016 are as follows: es and budgeted data budgeted information Ich) pin enable Eason to achie (OH) costs. Thener Prodetermined a In 2019 Eason's managers used the same indirect manufacturing costs per whoel rim that they computed in 2018 using activity-based costing. In addition to the unit indirect manufacturing costs, the following data are expected for the company's standard and deluxe models for 2019 Standard Deluxe Sales price 800.00 $ 940,00 Direct materials 31.00 48.00 Direct labor 45.00 52.00 Quantity of Predetermined Allocated activity location Overhead allocation cost per rim ABC cost per unit base used rata (Deluxe) Material handling 70 4.00 $ 28.00 Machine setups 0.036 400.00 - 14.40 Insertion of parts 70 26.00 - 182.00 Finishing direct labor hours 5.5 S 90.00 495.00 Total $ 719.40 the input fields and the Print Done Clear All mig. Overhead costs More Info Market research shows that for the deluxe rim to provide a reasonable profit, Eason will have to meet a target manufacturing cost of 625.00 per rim. A value engineering study by Eason's employees suggests that modifications to the finishing process could cut finishing cost from $90.00 to $60.00 per hour and reduce the finishing direct labor hours per deluxe rim from 5.5 hours to 5.0 hours. Direct materials would remain unchanged at $48.00 per rim, as would direct labor at $52.00 per rim. The materials handling, machine setup, and insertion of parts activity costs also would remain the same. Print Done then clickchool late Allocated mfg. overhead costs i More Info - X Market research shows that for the deluxe rim to provide a reasonable profit, Eason will have to meet a target manufacturing cost of 625.00 per rim. A value engineering study by Eason's employees suggests that modifications to the finishing process could cut finishing cost from $90.00 to $60.00 per hour and reduce the finishing direct labor hours per deluxe rim from 5.5 hours to 5.0 hours. Direct materials would remain unchanged at $48.00 per rim, as would direct labor at $52.00 per rim. The materials handling, machine setup, and insertion of parts activity costs also would remain the same. Print Done Click Check Answer X 19-22 (book/static) Canonywhere in 2011 mayroll the model onder de become 2018 How More commandation to start - Acco JS ABC allocation rates for 2018. Eason produces two wheel rim Controller Michael Bender is surprised by the increase in cost of the de conducted data.) arket research.) - X mmendation enable Eas ation and the del Data Table nen enter the am med OH allocatio Activity Materials handling Machine setup Insertion of parts Finishing Allocation Base Number of parts Number of setups Number of parts Number of finishing hours Predetermined Overhead Allocation Rate $4.00 per part 400.00 per setup 26.00 per part 90.00 per hour Standard 40 18.0 Deluxe 7.0 18.0 Parts per rim Setups per 500 rims Finishing hours per rim Total direct labor hours per rim 1.0 5.5 5.0 6.0 Print Done and then click Check Answer X post of the deluxe model Data Table stroller budgolod ABC 016 are as follows: es and budgeted data budgeted information Ich) pin enable Eason to achie (OH) costs. Thener Prodetermined a In 2019 Eason's managers used the same indirect manufacturing costs per whoel rim that they computed in 2018 using activity-based costing. In addition to the unit indirect manufacturing costs, the following data are expected for the company's standard and deluxe models for 2019 Standard Deluxe Sales price 800.00 $ 940,00 Direct materials 31.00 48.00 Direct labor 45.00 52.00 Quantity of Predetermined Allocated activity location Overhead allocation cost per rim ABC cost per unit base used rata (Deluxe) Material handling 70 4.00 $ 28.00 Machine setups 0.036 400.00 - 14.40 Insertion of parts 70 26.00 - 182.00 Finishing direct labor hours 5.5 S 90.00 495.00 Total $ 719.40 the input fields and the Print Done Clear All mig. Overhead costs More Info Market research shows that for the deluxe rim to provide a reasonable profit, Eason will have to meet a target manufacturing cost of 625.00 per rim. A value engineering study by Eason's employees suggests that modifications to the finishing process could cut finishing cost from $90.00 to $60.00 per hour and reduce the finishing direct labor hours per deluxe rim from 5.5 hours to 5.0 hours. Direct materials would remain unchanged at $48.00 per rim, as would direct labor at $52.00 per rim. The materials handling, machine setup, and insertion of parts activity costs also would remain the same. Print Done then clickchool late Allocated mfg. overhead costs i More Info - X Market research shows that for the deluxe rim to provide a reasonable profit, Eason will have to meet a target manufacturing cost of 625.00 per rim. A value engineering study by Eason's employees suggests that modifications to the finishing process could cut finishing cost from $90.00 to $60.00 per hour and reduce the finishing direct labor hours per deluxe rim from 5.5 hours to 5.0 hours. Direct materials would remain unchanged at $48.00 per rim, as would direct labor at $52.00 per rim. The materials handling, machine setup, and insertion of parts activity costs also would remain the same. Print Done Click Check