Answered step by step

Verified Expert Solution

Question

1 Approved Answer

You are back in the business of producing domestic fuel gas from fatty esters (waste cooking oil). With a newly developed catalyst, fatty esters

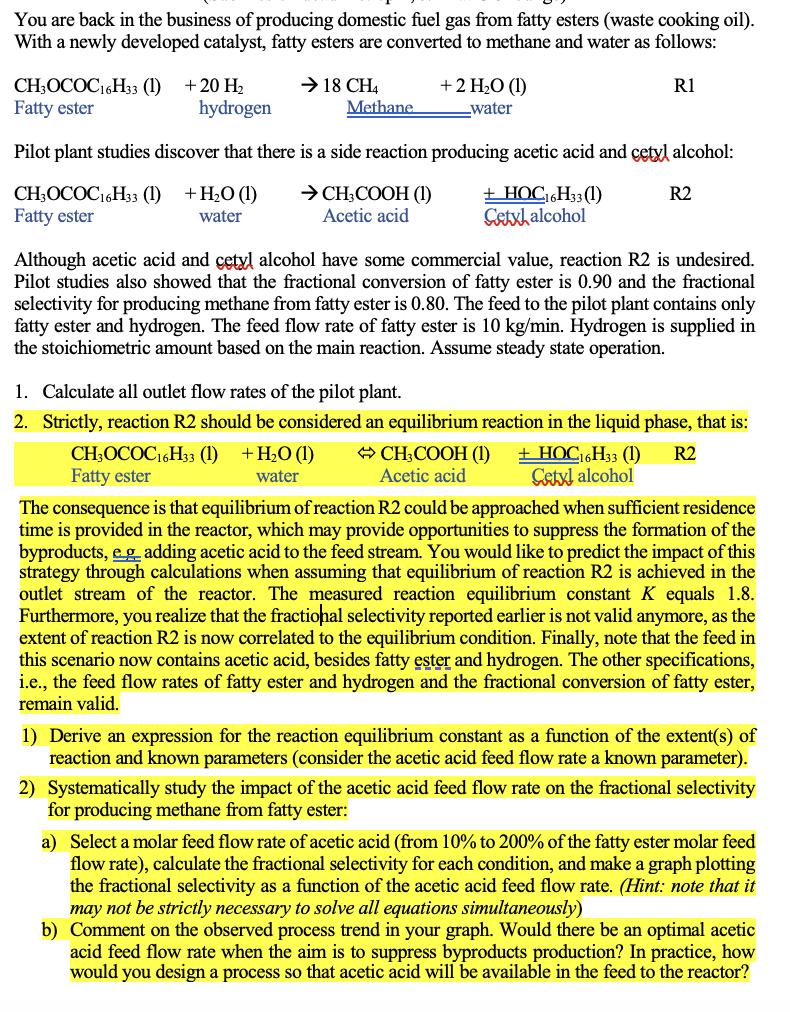

You are back in the business of producing domestic fuel gas from fatty esters (waste cooking oil). With a newly developed catalyst, fatty esters are converted to methane and water as follows: CH3OCOC16H33 (1) + 20 H2 18 CH4 + 2 HO (1) Fatty ester hydrogen Methane water R1 Pilot plant studies discover that there is a side reaction producing acetic acid and cetyl alcohol: CH3OCOC16H33 (1) + H2O (1) Fatty ester water CH3COOH (1) Acetic acid + HOC16H33 (1) Cetyl alcohol R2 Although acetic acid and cetyl alcohol have some commercial value, reaction R2 is undesired. Pilot studies also showed that the fractional conversion of fatty ester is 0.90 and the fractional selectivity for producing methane from fatty ester is 0.80. The feed to the pilot plant contains only fatty ester and hydrogen. The feed flow rate of fatty ester is 10 kg/min. Hydrogen is supplied in the stoichiometric amount based on the main reaction. Assume steady state operation. 1. Calculate all outlet flow rates of the pilot plant. 2. Strictly, reaction R2 should be considered an equilibrium reaction in the liquid phase, that is: CH3COOH (1) + HOC16H33 (1) R2 Acetic acid Cetyl alcohol CH3OCOC16H33 (1) + H2O (1) Fatty ester water The consequence is that equilibrium of reaction R2 could be approached when sufficient residence time is provided in the reactor, which may provide opportunities to suppress the formation of the byproducts, eg adding acetic acid to the feed stream. You would like to predict the impact of this strategy through calculations when assuming that equilibrium of reaction R2 is achieved in the outlet stream of the reactor. The measured reaction equilibrium constant K equals 1.8. Furthermore, you realize that the fractional selectivity reported earlier is not valid anymore, as the extent of reaction R2 is now correlated to the equilibrium condition. Finally, note that the feed in this scenario now contains acetic acid, besides fatty ester and hydrogen. The other specifications, i.e., the feed flow rates of fatty ester and hydrogen and the fractional conversion of fatty ester, remain valid. 1) Derive an expression for the reaction equilibrium constant as a function of the extent(s) of reaction and known parameters (consider the acetic acid feed flow rate a known parameter). 2) Systematically study the impact of the acetic acid feed flow rate on the fractional selectivity for producing methane from fatty ester: a) Select a molar feed flow rate of acetic acid (from 10% to 200% of the fatty ester molar feed flow rate), calculate the fractional selectivity for each condition, and make a graph plotting the fractional selectivity as a function of the acetic acid feed flow rate. (Hint: note that it may not be strictly necessary to solve all equations simultaneously) b) Comment on the observed process trend in your graph. Would there be an optimal acetic acid feed flow rate when the aim is to suppress byproducts production? In practice, how would you design a process so that acetic acid will be available in the feed to the reactor?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started