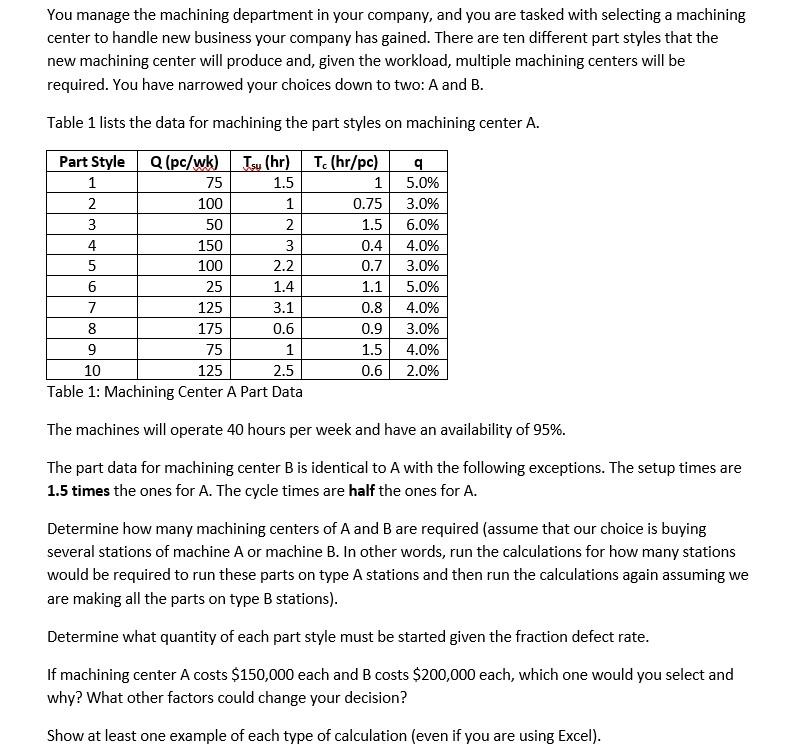

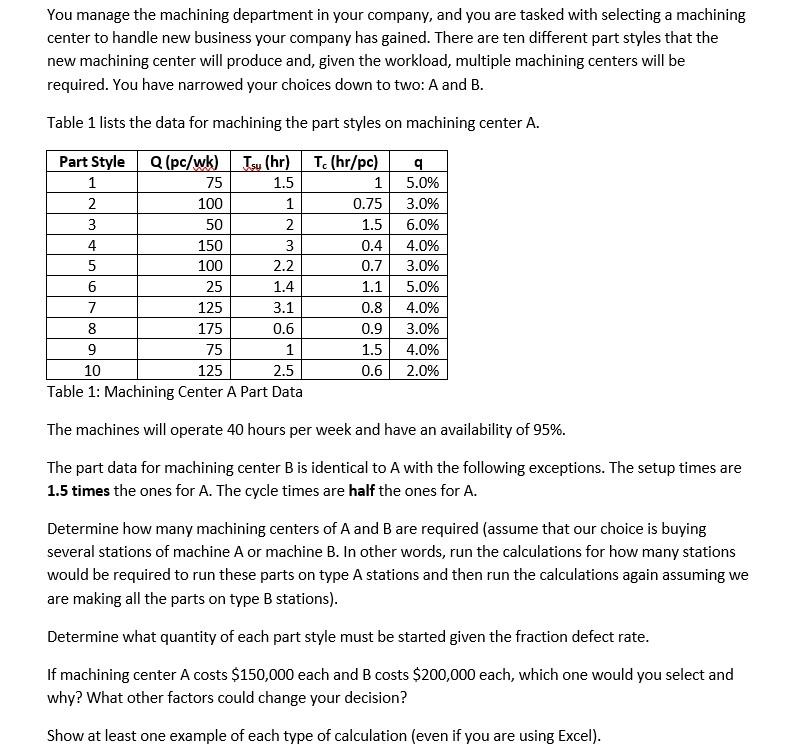

You manage the machining department in your company, and you are tasked with selecting a machining center to handle new business your company has gained. There are ten different part styles that the new machining center will produce and, given the workload, multiple machining centers will be required. You have narrowed your choices down to two: A and B. Table 1 lists the data for machining the part styles on machining center A. Table 1: Machining Center A Part Data The machines will operate 40 hours per week and have an availability of 95%. The part data for machining center B is identical to A with the following exceptions. The setup times are 1.5 times the ones for A. The cycle times are half the ones for A. Determine how many machining centers of A and B are required (assume that our choice is buying several stations of machine A or machine B. In other words, run the calculations for how many stations would be required to run these parts on type A stations and then run the calculations again assuming we are making all the parts on type B stations). Determine what quantity of each part style must be started given the fraction defect rate. If machining center A costs $150,000 each and B costs $200,000 each, which one would you select and why? What other factors could change your decision? Show at least one example of each type of calculation (even if you are using Excel). You manage the machining department in your company, and you are tasked with selecting a machining center to handle new business your company has gained. There are ten different part styles that the new machining center will produce and, given the workload, multiple machining centers will be required. You have narrowed your choices down to two: A and B. Table 1 lists the data for machining the part styles on machining center A. Table 1: Machining Center A Part Data The machines will operate 40 hours per week and have an availability of 95%. The part data for machining center B is identical to A with the following exceptions. The setup times are 1.5 times the ones for A. The cycle times are half the ones for A. Determine how many machining centers of A and B are required (assume that our choice is buying several stations of machine A or machine B. In other words, run the calculations for how many stations would be required to run these parts on type A stations and then run the calculations again assuming we are making all the parts on type B stations). Determine what quantity of each part style must be started given the fraction defect rate. If machining center A costs $150,000 each and B costs $200,000 each, which one would you select and why? What other factors could change your decision? Show at least one example of each type of calculation (even if you are using Excel)