Answered step by step

Verified Expert Solution

Question

1 Approved Answer

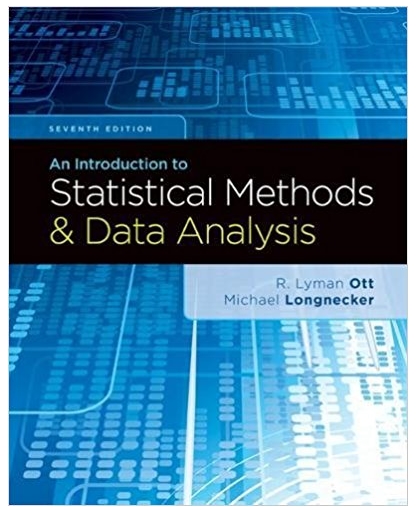

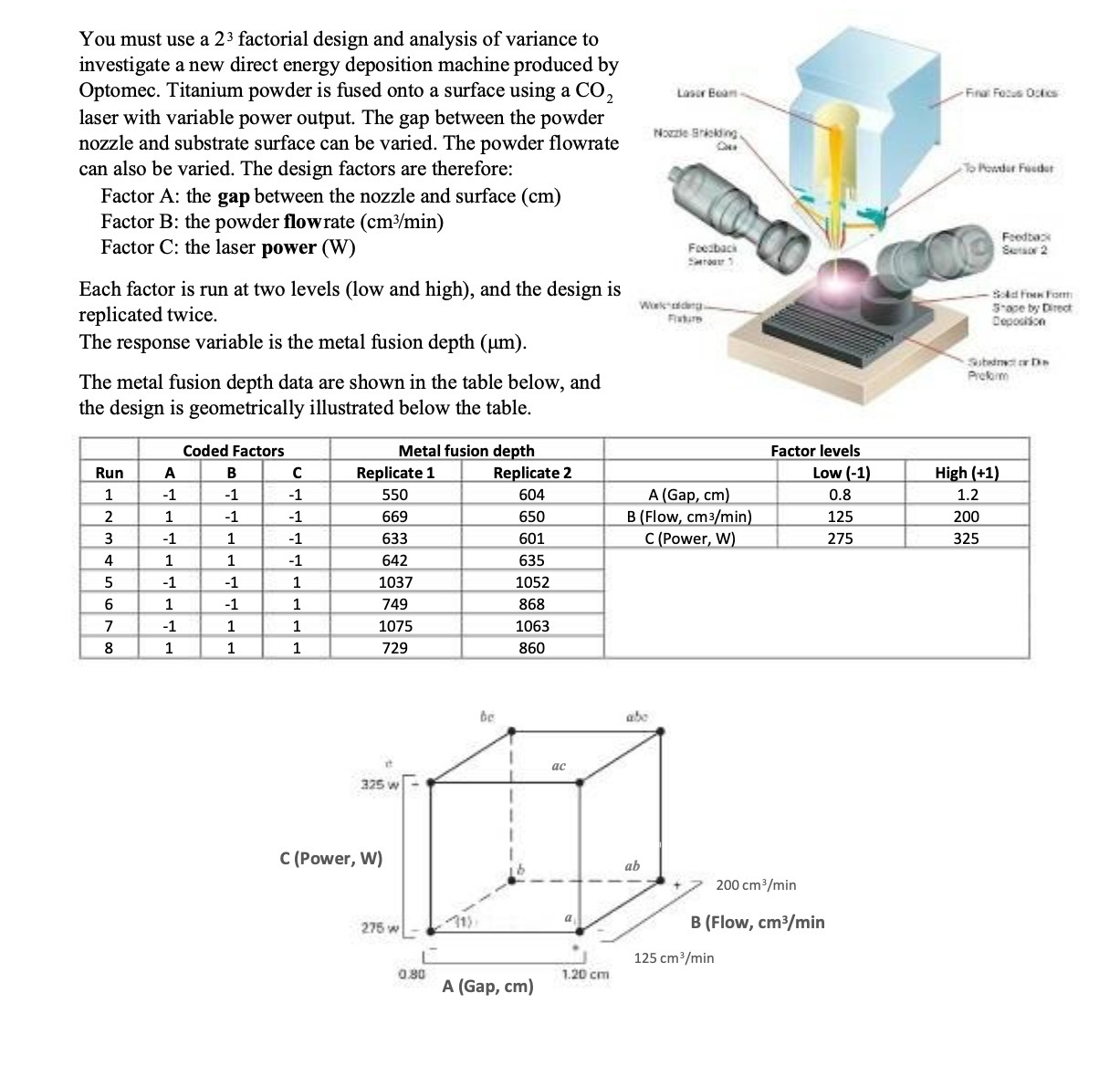

You must use a 23 factorial design and analysis of variance to investigate a new direct energy deposition machine produced by Optomec. Titanium powder

You must use a 23 factorial design and analysis of variance to investigate a new direct energy deposition machine produced by Optomec. Titanium powder is fused onto a surface using a CO laser with variable power output. The gap between the powder nozzle and substrate surface can be varied. The powder flowrate can also be varied. The design factors are therefore: Factor A: the gap between the nozzle and surface (cm) Factor B: the powder flowrate (cm/min) Factor C: the laser power (W) Each factor is run at two levels (low and high), and the design is replicated twice. The response variable is the metal fusion depth (um). The metal fusion depth data are shown in the table below, and the design is geometrically illustrated below the table. Laser Beam Nozzle Brickding Foodback Wok deng Fixture Final Focus Octics To Powder Foder Feedback S2 -Sold Frek Form Shape by Direct Deposition Subador De Preform Coded Factors Metal fusion depth Factor levels Run A B Replicate 1 Replicate 2 Low (-1) High (+1) 1 -1 -1 -1 550 604 A (Gap, cm) 0.8 1.2 2 1 -1 -1 669 650 B (Flow, cm/min) 125 200 3 -1 1 -1 633 601 C (Power, W) 275 325 4 1 1 -1 642 635 5 -1 -1 1 1037 1052 6 1 -1 1 749 868 7 -1 1 1 1075 1063 8 1 1 1 729 860 325 w C (Power, W) 275 w be ac abe ab 200 cm/min B (Flow, cm/min 125 cm/min 0.80 1.20 cm A (Gap, cm)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started