Answered step by step

Verified Expert Solution

Question

1 Approved Answer

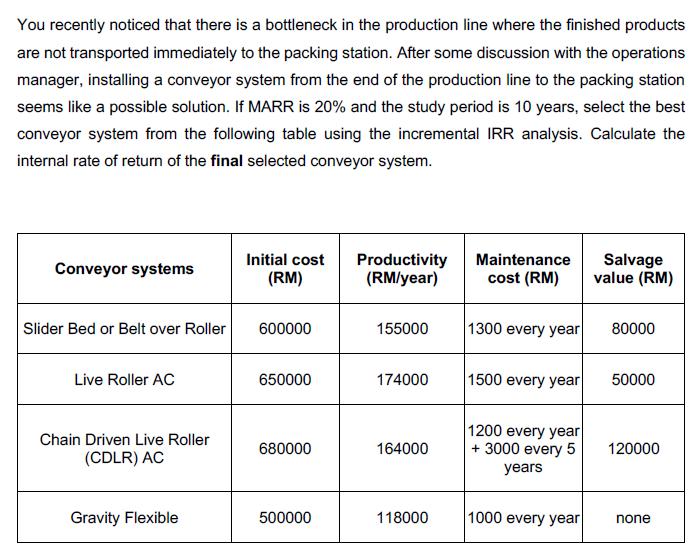

You recently noticed that there is a bottleneck in the production line where the finished products are not transported immediately to the packing station.

You recently noticed that there is a bottleneck in the production line where the finished products are not transported immediately to the packing station. After some discussion with the operations manager, installing a conveyor system from the end of the production line to the packing station seems like a possible solution. If MARR is 20% and the study period is 10 years, select the best conveyor system from the following table using the incremental IRR analysis. Calculate the internal rate of return of the final selected conveyor system. Conveyor systems Initial cost Productivity (RM) Maintenance (RM/year) cost (RM) Salvage value (RM) Slider Bed or Belt over Roller 600000 155000 1300 every year 80000 Live Roller AC 650000 174000 1500 every year 50000 Chain Driven Live Roller 680000 164000 (CDLR) AC 1200 every year + 3000 every 5 years 120000 Gravity Flexible 500000 118000 1000 every year none

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started