Goodstone Tire & Rubber Company is interested in monitoring the proportion of defective tires generated by the

Question:

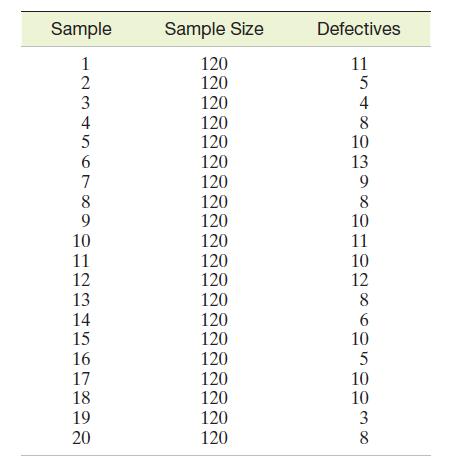

Goodstone Tire & Rubber Company is interested in monitoring the proportion of defective tires generated by the production process at its Akron, Ohio, production plant. The company’s chief engineer believes that the proportion is about 7%. Because the tires are destroyed during the testing process, the company would like to keep the number of tires tested to a minimum. However, the engineer would also like to use a p-chart with a positive lower control limit. A positive lower control limit makes it possible to determine when the process has generated an unusually small proportion of defectives. Such an occurrence is good news and would signal the engineer to look for causes of the superior performance. That information can be used to improve the production process. Using the sample size formula, the chief engineer recommended that the company randomly sample and test 120 tires from each day’s production. To date, 20 samples have been taken. The data are presented here.

a. Use the sample size formula to show how the chief engineer arrived at the recommended sample size of 120.

b. Construct a p-chart for the tire production process.

c. What does the chart indicate about the stability of the process? Explain.

d. Is it appropriate to use the control limits to monitor future process output? Explain.

e. Is the p-chart you constructed in part b capable of signaling hour-to-hour changes in p? Explain.

Step by Step Answer:

Statistics For Business And Economics

ISBN: 9780136855354

14th Edition

Authors: James T. McClave, P. George Benson, Terry T Sincich