A manufacturer of golf clubs has received numerous complaints about the performance of its graphite shafts. To

Question:

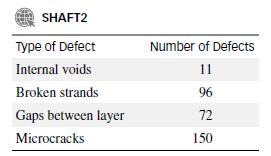

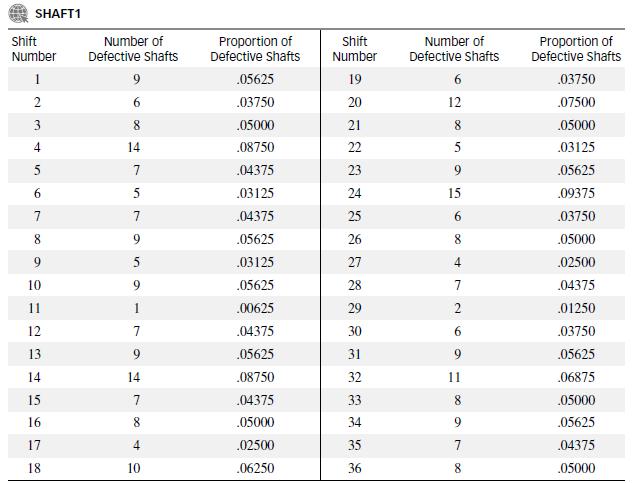

A manufacturer of golf clubs has received numerous complaints about the performance of its graphite shafts. To monitor the shaft production process, a pultrusion method was used. A fabric is pulled through a thermosetting polymer bath and then through a long, heated steel die. As it moves through the die, the shaft is cured. Finally, it is cut to the desired length. Defects that can occur during the process are internal voids, broken strands, gaps between successive layers, and microcracks caused by improper curing. The quality department sampled 10 consecutive shafts every 30 minutes and nondestructive testing was used to seek out flaws in the shafts. The data from each 8-hour work shift were combined to form a shift sample of 160 shafts. Data on the proportion of defective shafts for 36 shift samples are presented in the table. Data on the types of flaws identified are shown below.

a. Use the appropriate control chart to determine whether the process proportion remains stable over time.

b. To help diagnose the causes of variation in process output, construct a Pareto diagram for the types of shaft defects observed. Which are the “vital few”? The “trivial many”?

Step by Step Answer:

Statistics For Engineering And The Sciences

ISBN: 9781498728850

6th Edition

Authors: William M. Mendenhall, Terry L. Sincich