Tiffany Chen was concerned about Winner Apparels sales results from the previous season. For some products, the

Question:

The Previous Season for Winner Apparel

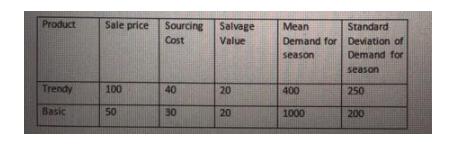

Tiffany decided to focus on a couple of products that had problems last season. “Trendy” was a collection of women’s shirts that,

as the name suggested, incorporated cutting-edge fashion. The buying committee had been bullish on the new designs and ordered 570 units for the season. Unfortunately, 250 of those units were still unsold at the end of the season. Trendy shirts sold at a full price of $100, but for the 250 units unsold at the end of the season, Winner would be able to salvage only $20/unit. This was a significant loss, given that each unit had been purchased for $40. In contrast, “Basic” was a collection of Tshirts that Winner always maintained in its portfolio. The buying committee had ordered 1,080 Basic units, but Winner ran out of stock before the end of the season. Tiffany’s team estimated that the company could have sold another 60 units if stock had been available. Given that Winner had a margin of $20 for each Basic T-shirt, the company had lost $1,200 in margin because of being out of stock.

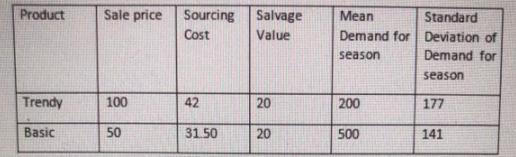

Proposal from Responsive Supplier

A local supplier had heard that Tiffany was reconsidering product sourcing. It proposed filling Winner’s needs in two deliveries. The first delivery would arrive before the start of the season and be designed to cover about a half-season of sales. The second delivery would arrive around the middle of the season, but the timing and quantity could be adjusted to account for sales in the first half. The supplier promised delivery to ensure no stockouts during the first half. In other words, the supplier would bring in the second delivery early (and a larger quantity) if sales in the first half seemed to be higher than predicted. If sales in the first half were slower than anticipated, Winner could reduce the amount ordered for the second delivery. For this flexibility, the local supplier wanted a premium of 5 percent compared to the low-cost supplier. If purchased from the local supplier, the Trendy line would thus cost $42 (instead of $40) per unit and the Basic line would cost $31.50 (instead of $30). Tiffany felt that with a mid-season delivery, any customers who could not find product during the first half of the season would return for the second half and purchase the item. Thus, there would be no lost sales during the first half of the season. Her team prepared the demand and cost data shown in Table 13-8 and 13-9. Tiffany had to decide whether the responsiveness of the local supplier was worth the additional 5 percent in unit cost.

Table 13-8

Table 13-9

Step by Step Answer:

Supply Chain Management Strategy Planning And Operation

ISBN: 9781292257891

7th Global Edition

Authors: Sunil Chopra