Toyota has decided to set up regional warehouses where some variants of the Scion will be customized

Question:

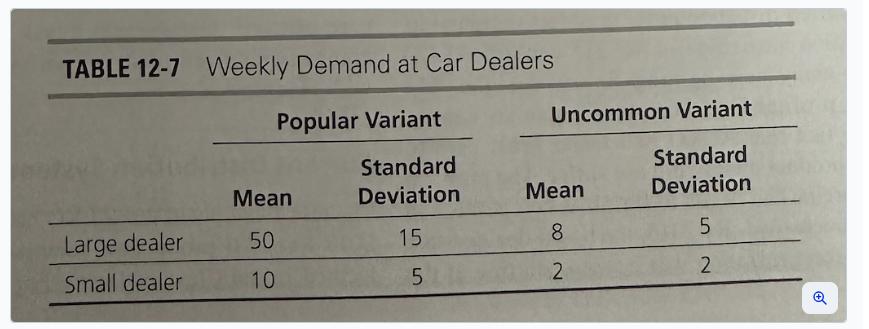

Toyota has decided to set up regional warehouses where some variants of the Scion will be customized and shipped to dealers on demand. Customizing and shipping on demand will raise production and transportation cost per car by $100. Each car costs $20,000, and Toyota has an annual holding cost of 20 percent. Cars at the dealer are owned by Toyota for the first 90 days. Thus, for all practical purposes, Toyota owns all inventory, whether at the dealers or at the regional warehouse. Consider a region with five large dealers and thirty small dealers. Toyota has partitioned the variants into two groups—popular variants and uncommon variants. Weekly demand for the two types of variants at the two types of dealers is shown in Table 12-7. The goal is to provide a 95 percent cycle service level using a continuous review policy. Replenishment lead times for both dealers and regional warehouses are four weeks. Customization and shipping from a regional warehouse to a dealer can be done in a day, and this time can be ignored. Assume demand to be independent across all dealers.

a. How much safety inventory of a popular variant is required at a large or small dealer?

b. What is the safety inventory required if inventory for the popular variant (for both large and small dealers) is centralized at the regional warehouse by Toyota?

c. What is the safety inventory required if inventory for the popular variant at small dealers is centralized at the regional warehouse but that for large dealers is decentralized?

d. Given the additional customization and transportation cost, which structure do you recommend for the popular variant?

e. Repeat parts (a) to (d) for the uncommon variant.

f. How should Toyota structure inventories given its regional warehouses?

Step by Step Answer:

Supply Chain Management Strategy Planning And Operation

ISBN: 9781292257891

7th Global Edition

Authors: Sunil Chopra