A multistage vapor compression refrigeration system with flash gas removal is being used to maintain a cold

Question:

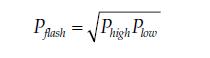

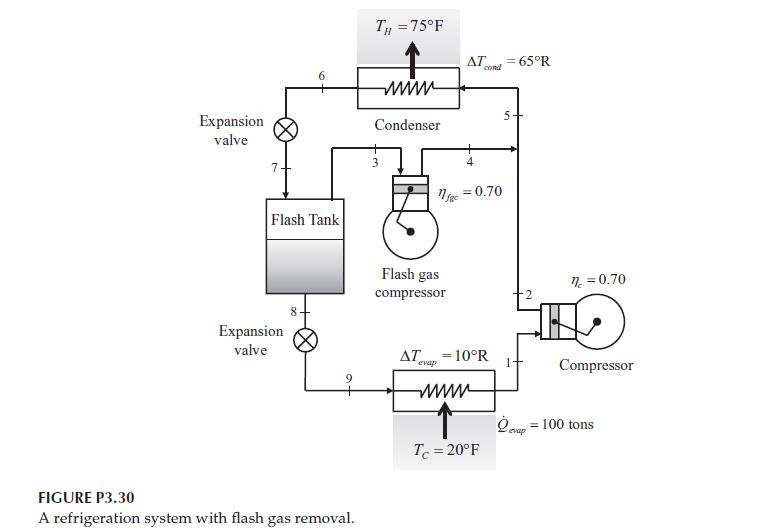

A multistage vapor compression refrigeration system with flash gas removal is being used to maintain a cold space at TC = 20°F for frozen food storage as shown in Figure P3.30. The system utilizes R134a as the working fluid. The cycle is providing 100 tons of cooling capacity to the cold space. Heat is rejected to the surroundings at TH = 75°F in the condenser. The pinch point temperature differences for the condenser and evaporator are ΔTcond = 65°R and ΔTevap = 10°R, respectively. The refrigerant enters the compressor as a saturated vapor and it leaves the condenser as a saturated liquid. The isentropic efficiency of the main compressor is ηc = 0.70 and the isentropic efficiency of the flash gas compressor is ηfgc = 0.72. The flash tank is operating at an estimated optimum pressure given by,

where Phigh and Plow are the highest and lowest pressures in the system, respectively.

For this system, determine the following,

a. The total power draw of the compressors (hp)

b. The cooling COP and HPT of the system Verify that the flash gas removal cycle is more efficient than a single-stage vapor compression refrigeration cycle providing 100 tons of cooling and operating between TC and TH by calculating,

c. The power draw of the compressor for the single-stage cycle (hp)

d. The cooling COP and HPT of the single-stage system The operating pressure of the flash tank is controlled by the expansion valve directly after the condenser. Modern expansion valves are adjustable, offering a wide range of pressure drops across the device,

e. Investigate the effect of adjusting the expansion valve by constructing a plot that shows the cooling COP as a function of the flash tank pressure. You should discover that there is an optimum flash tank pressure. Is the flash tank pressure estimate a reasonable approximation to this optimum pressure?

Step by Step Answer:

Thermal Energy Systems Design And Analysis

ISBN: 9781138735897

2nd Edition

Authors: Steven G. Penoncello