Question:

The Allbright BrickWorks, in Winnipeg, manufactures high-quality bricks used in residential and commercial construction. The firm is small but highly automated and typically produces about 300,000 bricks per month. A brick is created in a continuous production operation. In the initial step, the raw material, a mixture of soils and water, is forced into a brick mould moving along a conveyer belt. No other materials are required in the manufacture of a brick. Each brick takes about three days to complete. They spend the last 36 hours or soon the conveyer belt in an oven that removes moisture from the product. The conveyer belt speed is monitored and controlled by computer. The firm uses a process costing system based on actual costs in three cost pools-direct materials, direct labour, and factory overhead-to assign production costs to output. Cost and production data for October 2016 follow:

.png)

Instructions

Determine the cost of bricks transferred to finished goods inventory and the cost of bricks in ending work in process inventory for October 2016. Assume the company uses the FIFO method.

(Adapted from CGA-Canada, now CPA Canada)

Transcribed Image Text:

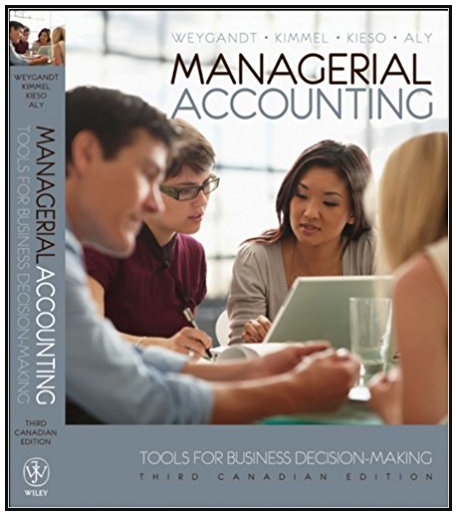

Production Data Beginning work in process inventory (100% complete in terms of direct materials; 60% complete in terms of direct labour; 36% complete in terms of factory overhead) 35,000 bricks 295,000 bricks Started this period Ending work in process inventory (100% complete in terms of direct materials; 50% complete in terms of direct labour; 40% complete in terms of factory overhead) 30,000 bricks Cost Data Beginning inventory Cost in October Materials $ 1,330 12,200 Direct Labour $ 435 15,000 Overhead $ 852 18,180

.png)