Question:

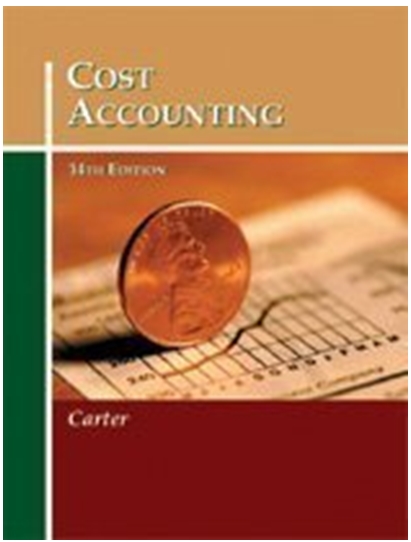

Upton Manufacturing Company manufactures a single model of a portable work bench. The company uses a process cost system, with a fifo cost flow assumption, and it maintains a separate work in process account for each of its two producing departments, Cutting and Assembly. The work bench components are cut out of wood and metal in the Cutting Department and then transferred to the Assembly Department, where they are put together with the addition of springs, hinges, and handles purchased from outside vendors. Data related to operations in October are:

Required:

(1) Prepare an October cost of production report for each department.

(2) Prepare the appropriate general journal entries to record the charge to the producing departments for the costs incurred during October and to record the transfer of units from Cutting to Assembly and from Assembly to Finished Goods Inventory.

Transcribed Image Text:

Cutting Assembl Units in beginning inventory: Cutting (90% materials, 40% labor 1,000 and 20% overhead) Assembly (75% materials, 60% labor, and 60% overhead) Units started in process in Cutting 2,000 Department this period Units transferred from Cutting to Assembly this period 9,000 8,500 8,500 Units transferred from Assembly to Finished Goods this period 9,500 Units in ending inventory: Cutting (100% materials, 80% labor, and 100% overhead) Assembly (60% materials, 40% labor 1,500 and 40% overhead) 1,000 Cost in beginning inventory: Cost from preceding department S 4,000 Materials Labor Factory overhead. $ 8,010 1,750 790 9 1,600 Cost added during the current period 30,100 21,315 30,015 Materials 2 18,600 39,200 Factory overhead

.png)