Waste heat recovery from the exhaust (flue) gas of a melting furnace is accomplished by passing the

Question:

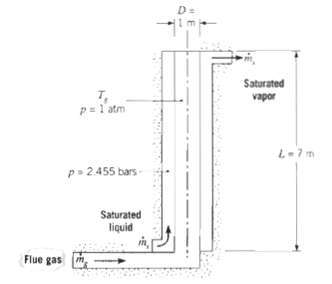

Waste heat recovery from the exhaust (flue) gas of a melting furnace is accomplished by passing the gas through a vertical metallic tube and introducing saturated water (liquid) at the bottom of an annular region around the tube. The tube length and inside diameter are 7 and 1 m, respectively, and the tube inner surface is black. The gas in the tube is at atmospheric pressure, with CO2 and H2O (v) partial pressures of 0.1 and 0.2 atm, respectively, and its mean temperature may be approximated as Tg = 1400 K. The gas flow rate is mg = 2 kg/s. If saturated water is introduced at a pressure of 2.455 bars, estimate the water flow rate ms for which there is complete conversion from saturated liquid at the inlet to saturated vapor at the outlet. Thermo physical properties of the gas may be approximated as ? = 530 X 10-7 kg/s ??? m, k = 0.091 W/m ??? K, and Pr = 0.70.

Step by Step Answer:

Fundamentals of Heat and Mass Transfer

ISBN: 978-0471457282

6th Edition

Authors: Incropera, Dewitt, Bergman, Lavine