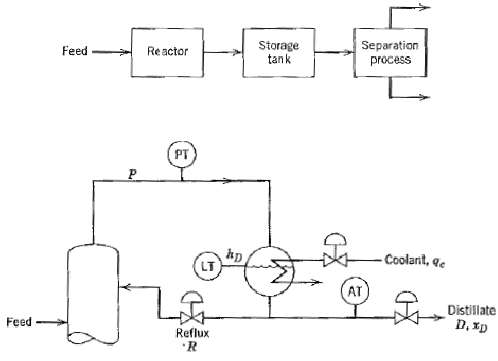

Question: It has been suggested that the capital cost for the distillation column in figure can be reduced by using a ?flooded condenser.? In the proposed

It has been suggested that the capital cost for the distillation column in figure can be reduced by using a ?flooded condenser.? In the proposed design, the reflux drum would be eliminated, and the condensed vapor in the condenser would provide the liquid inventory for the reflux and distillate streams, as shown In Figure. As a result, the coolant tubes in the condenser would he partially covered (or ?flooded?), and the area available for heat transfer would change as the liquid level changes. Discuss the dynamic and control implications of this proposed process change for both pressure control and liquid-level control. You may assume that the conventional control configuration for this column is to control column pressure P by manipulating coolant flow rate qC, and liquid level h by manipulating distillate flow rate D.

Storage tank Separation process Feed Reactor PT ap LT Coolarit, ee AT Distillate Feed D, xp Reflux R

Step by Step Solution

3.55 Rating (173 Votes )

There are 3 Steps involved in it

For the flooded condenser in Figure the area available for ... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

38-E-C-E-P-C (145).docx

120 KBs Word File