It is desired to control the exit concentration of c3 of the liquid blending system shown in

Question:

It is desired to control the exit concentration of c3 of the liquid blending system shown in Figure. Using the information given below, do the following:

(a) Draw a block diagram for the composition control scheme. (Use the symbols in the figure as much as possible.)

(b) Derive an expression for each transfer function and substitute numerical values.

(c) Suppose that the PI controller has been tuned for the nominal set of operating conditions below. Indicate whether the controller should be retuned for each of the following situations. (Briefly justify your answers.)

(i) The nominal value of c2 changes to c2 = 8.5 lb solute/ft3.

(ii) The span of the composition transmitter is adjusted so that the transmitter output varies from 4 to 20mA as c3 varies from 3 to 14 lb solute/ft3.

(iii) The zero of the composition transmitter is adjusted so that the transmitter output varies from 4 to 20mA as c3 varies from 4 to 10 lb solute/ft3.

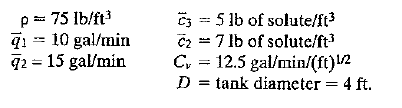

Available Information

1. The tank is perfectly mixed.

5. A 2-mm time delay is associated with the composition measurement. The transmission output signal varies linearly from 4 to 20mA as c3 varies from 3 to 9 lb solute/ft3.

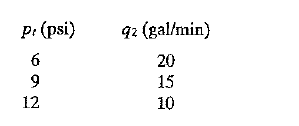

6. The pneumatic control valve has negligible dynamics. Its steady-state behavior is summarized below where is the air pressure signal to the control valve from the I/P transducer.

7. An electronic, direct-acting, P1 controller is used.

8. The current-to-pressure transducer has negligible dynamics and a gain of 0.3psi/mA.

9 The nominal operating conditionsare:

Step by Step Answer:

Process Dynamics And Control

ISBN: 978-0471000778

2nd Edition

Authors: Dale E. Seborg, Thomas F. Edgar, Duncan A. Mellich