Liquid benzene (specific gravity = 0.86) is to be heated in a counterflow concentric-pipe heat exchanger from

Question:

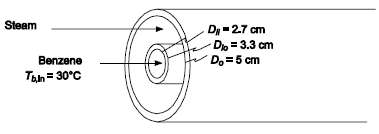

Liquid benzene (specific gravity = 0.86) is to be heated in a counterflow concentric-pipe heat exchanger from 30 to 90?C. For a tentative design, the velocity of the benzene through the inside pipe (ID = 2.7 cm; OD = 3.3 cm) can be taken as 8 m/s. Saturated process steam at 1.38 x 106 N/m2 is available for heating. Two methods of using this steam are proposed(a) Pass the process steam directly through the annulus of the exchanger; this would require that the letter be designed for the high pressure.(b) Throttle the steam adiabatically to 138,000 N/m2 before passing it through the heater. In both cases, the operation would be controlled so that saturated vapor enters and saturated water leaves the heater. As an approximation, assume that for both cases the heat transfer coefficient for condensing steam remains constant at 12,800 W/(m2 K), that the thermal resistance of the pipe wall is negligible, and that the pressure drop for the steam is negligible. If the inside diameter of the other pipe is 5 cm, calculate the mass rate of flow of steam (kg/s per pipe) and the length of heater required for each arrangement.GIVENA concentric pipe, counterflow heat exchanger - benzene in inner tube; saturated steam in annulusSpecific gravity of benzene (s.g.) = 0.86Benzene temperaturesTb,in = 30?CTb,out = 90?CPipe diametersDii = 2.7 cm = 0.027 mDio = 3.3 cm = 0.033 mDo = 5 cm = 0.05 mBenzene velocity (Vb) = 2.5 m/sSaturated steam pressure = 1.38 x 106 N/m2Saturated vapor enters condenser and saturated water leavesASSUMPTIONSThe heat transfer coefficient on the steam side (ho) = 12,800 W/(m2 K)The thermal resistance of the pipe wall is negligibleThe pressure drop for the steam isnegligible

Step by Step Answer:

Principles of heat transfer

ISBN: 978-0495667704

7th Edition

Authors: Frank Kreith, Raj M. Manglik, Mark S. Bohn