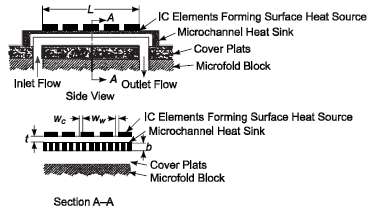

Microchannel compact heat exchangers can be used to cool high heat flux microelectronic devices. The sketch below

Question:

Microchannel compact heat exchangers can be used to cool high heat flux microelectronic devices. The sketch below shows a schematic view of a typical microchannel heat sink. Micro-fabrication techniques can be used to mass produce aluminum channels and fins with the following dimensions:Wc = Ww = 50 micrometersb = 200 micrometersL = 1.0 cmt = 100 micrometersAssuming there are a total of 100 fins and that water at 30?C is used as the cooling medium at a Reynolds number of 2000 estimate(a) The water flow rate through all the channels(b) The Nusselt number(c) The heat transfer coefficient(d) The effective thermal resistance between the IC elements forming the heat source and the cooling water(e) The rate of heat dissipation allowable if the temperature difference between source and water is not to exceed 100 K

GIVENAn aluminum microchannel heat exchanger as shown abovewc = ww = 50 micrometersb = 200 micrometersL = 1.0 cmt = 100 micrometersTotal number of fins (N) = 100Cooling water temperature (Tw) = 30?CReynolds number (Re) = 2000ASSUMPTIONSSteady stateUniform and constant heat generationThe heat generation chip is the same size as the heat exchangerA conducting paste has been applied between the heat sink and the IC to eliminate contact resistanceThe cover plate is aninsulator

Step by Step Answer:

Principles of heat transfer

ISBN: 978-0495667704

7th Edition

Authors: Frank Kreith, Raj M. Manglik, Mark S. Bohn