Question:

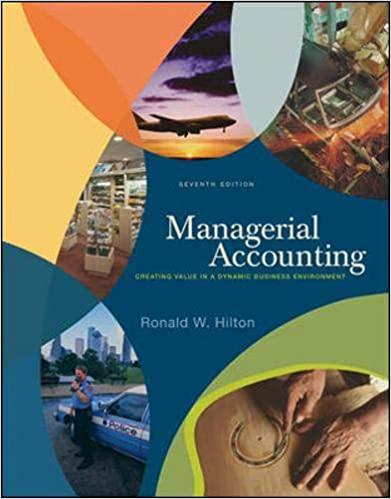

Pittsburgh Plastics Corporation manufactures a range of molded plastic products, such as kitchen utensils and desk accessories. The production process in the North Hills plant is a JIT system, which operates in four FMS cells. An AMHS is used to transport products between production operations. Each month, the controller prepares a production efficiency report, which is sent to corporate headquarters. The data compiled in these reports, for the first six months of the year, are as follows:

Required:

1. Write a memo to the company president evaluating the North Hills plant€™s performance. Structure your report by dividing it into the following parts:

(a) Product processing and productivity;

(b) Product quality and customer acceptance;

(c) Delivery performance;

(d) Raw material, scrap, and inventory; and

(e) Machine maintenance.

2. If you identify any areas of concern in your memo, indicate an appropriate action formanagement.

Transcribed Image Text:

PRODUCTION EFFICIENCY REPORT Pittsburgh Plastics Corporation North Hills Plant January through June Jan. Feb. Mar Ar May June Average 60 70 75 80 85 05 792 Overtime hours Total setup time Cycle time (average in hours).... Manufacturing-cycle efficiency. Percentage of orders filled 7 70 6 6 62 62 65.5 0 20 19 1 17 18.8 90% 100% 100% 5% 5% 5% 4% 5% 5% 4.8% 80 82 75 4025 22 54 g5% 100% 99% 94% 100% 98% 96% 100% 99% 89% 100% 96% 90% 100% 94% 92.3% 100% 97.7% Inventory value/sales revenue Number of defective units, finished goods Number of delective units, in process.10 Number of raw-material shipments with 5 40 60 6 39.2 defective materials. Number of products returned0 Aggregate productivity 1.313 12 125 12 15 123 Power consunption (thousands of kilowatt-hours) Machine downtime (hours). Bottleneck machine downtime. Number of unscheduled machine 800 795 802 800 800 800 30 25 25 20 2010 21.7 0 0 2 0 15 2 32 maintenance calls ..

.png)