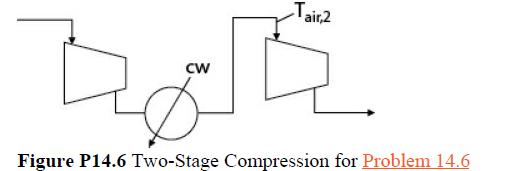

Consider the compression of feed air into a process that produces maleic anhydride, shown in Figure P14.6.

Question:

Consider the compression of feed air into a process that produces maleic anhydride, shown in Figure P14.6. The air enters the process at a rate of 10 kg/s at atmospheric pressure and 25°C. It is compressed to 3 atm in the first compressor. The compression is 65% efficient based on a reversible, adiabatic process. Prior to entering the second stage of compression (where the air is compressed to 9 atm at the same efficiency), the air flows through a water-cooled heat exchanger where the temperature is cooled to Tair,2.

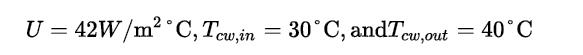

Assume that frictional pressure drops in the connecting pipes and in the exchangers are negligible. For the design of the exchanger, assume that

For economic calculations, assume the following:

The fixed capital investment is equal to the total module cost of the compressor (centrifugal), the compressor drive (electric), and heat exchanger (shell-and-tube, floating-head). The following equations should be used to evaluate these costs:![CTM, compr [$]= 12,500{P[kW]}0.68 CTM, drive [$] = 600{P[kW]}0. 0.82 CTM, exch [$] =2700{A[m]} 0.8 (P14.6.2)](https://dsd5zvtm8ll6.cloudfront.net/images/question_images/1699/3/4/9/574654a0446667871699349572799.jpg)

- Utility costs should be taken from Table 8.4, and use an electric drive efficiency of 95% and a 65% compressor efficiency.

- F factors should be calculated for the heat exchanger, and these will change as Tair,2 changes (see Chapter 15 for equations for F).

- Assume a hurdle rate of 8% and an equipment/project life of 5 years.

- Using results from a simulator, determine the optimum size (area) of the heat exchanger and the corresponding value of Tair,2.

Step by Step Answer:

Analysis Synthesis And Design Of Chemical Processes

ISBN: 9780134177403

5th Edition

Authors: Richard Turton, Joseph Shaeiwitz, Debangsu Bhattacharyya, Wallace Whiting