When a chemical plant needs steam at multiple pressure levels, it is often economical to generate all

Question:

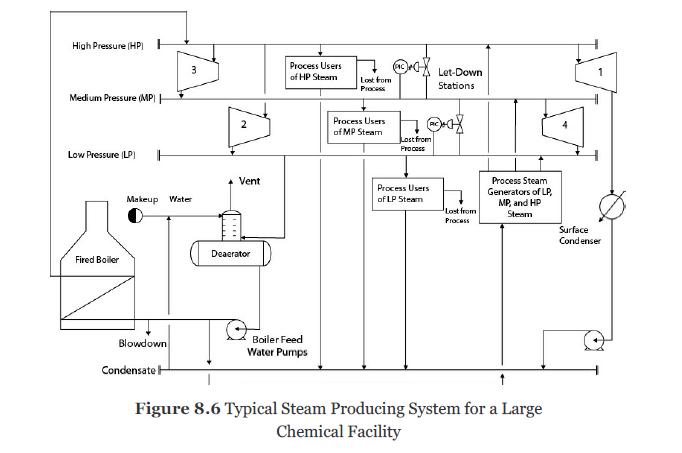

When a chemical plant needs steam at multiple pressure levels, it is often economical to generate all the steam at a high pressure and then to let the steam down through pressure-reducing turbines to the desired pressure. This principle is illustrated in Figure 8.6. The downside of this approach is that as the exhaust pressure of the turbine increases, the theoretical (and actual) steam requirements increase, meaning that less energy is extracted. To illustrate this point, do the following:

Estimate the amount of energy extracted from 10,000 kg/h of 58.6 barg steam superheated by 165°C when connected to the following turbines (each 80% efficient):

- Exhaust pressure is 4" Hg absolute.

- Exhaust pressure is 4.82 barg.

- Estimate the amount of energy extracted from 10,000 kg/h of saturated, 10.0 barg steam when connected to a turbine (80% efficient) exhausting at 4.82 barg.

- Identify the locations of each of the three turbines described above on Figure 8.6.

Step by Step Answer:

Analysis Synthesis And Design Of Chemical Processes

ISBN: 9780134177403

5th Edition

Authors: Richard Turton, Joseph Shaeiwitz, Debangsu Bhattacharyya, Wallace Whiting