Question: A piping system for transporting a liquid ( $mu=50 mathrm{cP}, ho=0.85 mathrm{~g} / mathrm{cm}^{3}$ from vessel A to vessel B) consists of $650 mathrm{ft}$ of

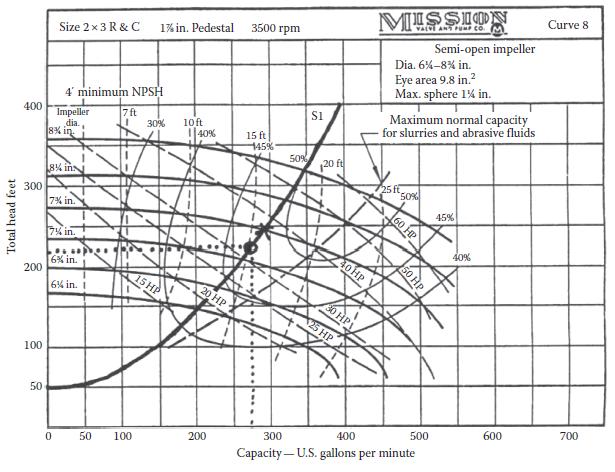

A piping system for transporting a liquid ( $\mu=50 \mathrm{cP}, ho=0.85 \mathrm{~g} / \mathrm{cm}^{3}$ from vessel A to vessel B) consists of $650 \mathrm{ft}$ of $3 \mathrm{in}$. sch 40 commercial steel pipe containing 4 globe valves and 10 elbows. The pressure is atmospheric in A and 5 psig B, and the liquid level in B is $10 \mathrm{ft}$ higher than that in A. You want to transfer the liquid at a rate of $250 \mathrm{gpm}$ at $80^{\circ} \mathrm{F}$ using a pump with the characteristics shown in Figure 8.2. Determine

Figure 8.2

(a) The diameter of the impeller that you would use with this pump

(b) The head developed by the pump and the power (in horsepower) required to pump the liquid

(c) The power of the motor required to drive the pump

(d) The torque that the motor must develop

(e) The NPSH of the pump at the operating conditions

Size 2 3 R & C 1% in. Pedestal 3500 rpm 4' minimum NPSH 400 Impeller dia. 300 200 8% in 8% in 7% in 7% in 6% in. 6% in. I Total head feet 100 50 MISSION VALVE AND PUMP COM Semi-open impeller Dia. 6%-8% in. Eye area 9.8 in. Curve 8 S1 20 ft Max. sphere 1% in. Maximum normal capacity for slurries and abrasive fluids 7ft 30% 10ft. 140% 15 ft 145% 50% 50 50 40HP 15 HP 20 HP 30 HP1 25 HP 25ft, 50% 45% 60 HP 50 HP 400 40% 500 600 700 Capacity-U.S. gallons per minute 100 200 300

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts