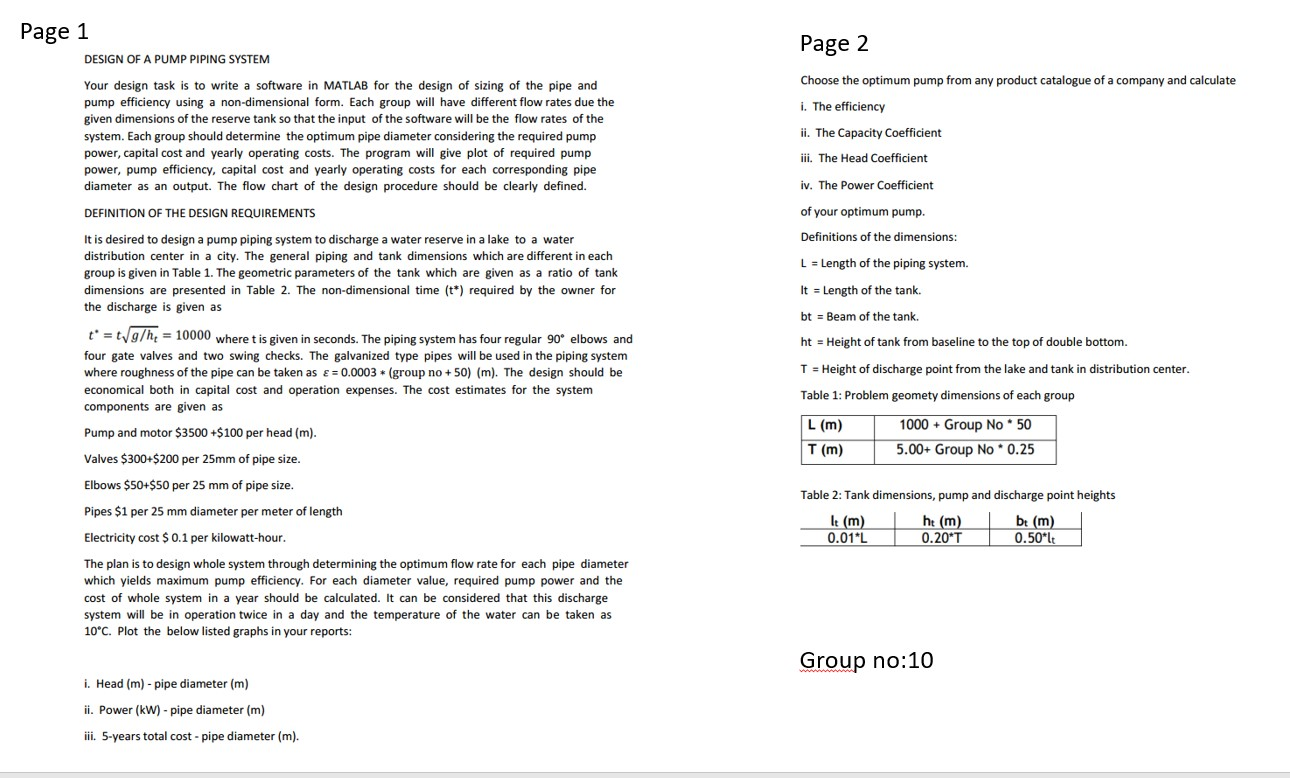

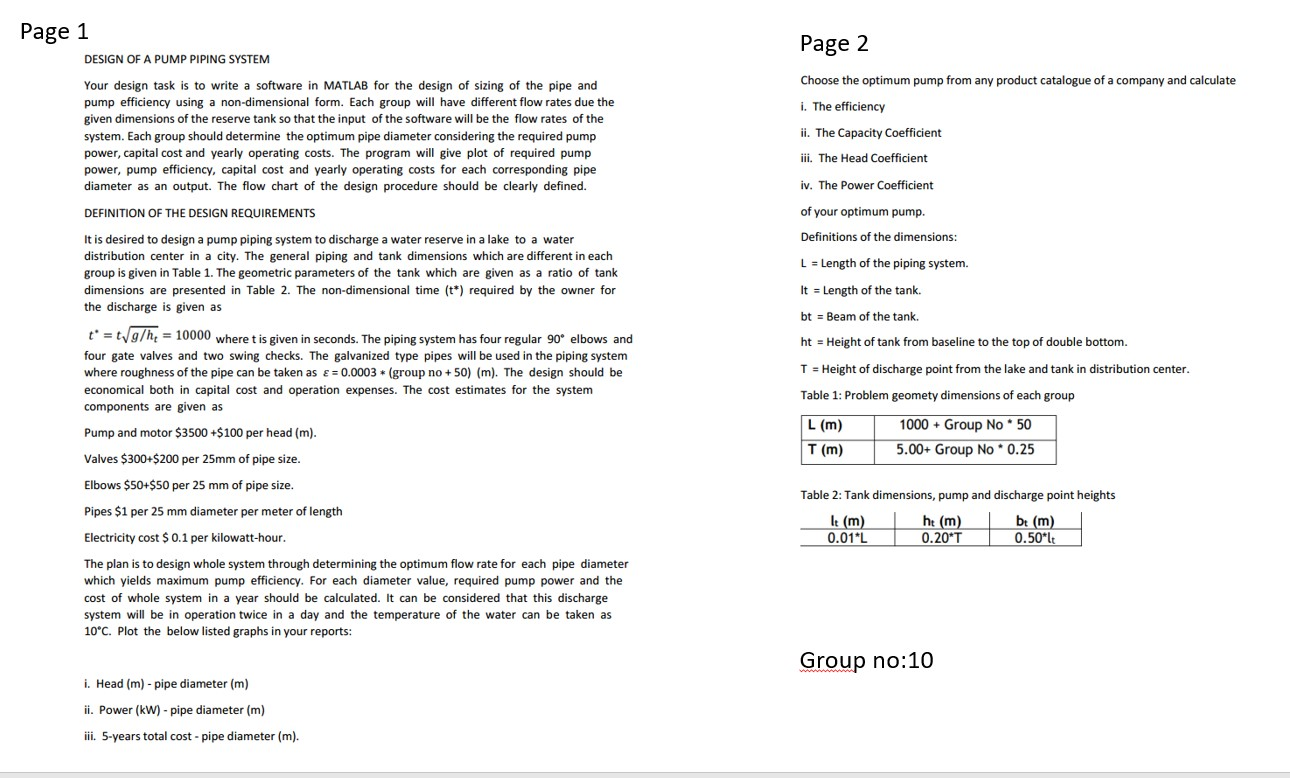

Page 1 DESIGN OF A PUMP PIPING SYSTEM Page 2 Choose the optimum pump from any product catalogue of a company and calculate i. The efficiency Your design task is to write a software in MATLAB for the design of sizing of the pipe and pump efficiency using a non-dimensional form. Each group will have different flow rates due the given dimensions of the reserve tank so that the input of the software will be the flow rates of the system. Each group should determine the optimum pipe diameter considering the required pump power, capital cost and yearly operating costs. The program will give plot of required pump power, pump efficiency, capital cost and yearly operating costs for each corresponding pipe diameter as an output. The flow chart of the design procedure should be clearly defined. ii. The Capacity Coefficient iii. The Head Coefficient iv. The Power Coefficient DEFINITION OF THE DESIGN REQUIREMENTS of your optimum pump. Definitions of the dimensions: L = Length of the piping system. It is desired to design a pump piping system to discharge a water reserve in a lake to a water distribution center in a city. The general piping and tank dimensions which are different in each group is given in Table 1. The geometric parameters of the tank which are given as a ratio of tank dimensions are presented in Table 2. The non-dimensional time (t*) required by the owner for the discharge is given as It = Length of the tank. bt = Beam of the tank. =tyg/h 10000 where t is given in seconds. The piping system has four regular 90 elbows and four gate valves and two swing checks. The galvanized type pipes will be used in the piping system where roughness of the pipe can be taken as E = 0.0003 * (group no +50) (m). The design should be economical both in capital cost and operation expenses. The cost estimates for the system components are given as ht = Height of tank from baseline to the top of double bottom. T = Height of discharge point from the lake and tank in distribution center. Table 1: Problem geomety dimensions of each group L (m) 1000 + Group No. 50 T(m) 5.00+ Group No 0.25 Pump and motor $3500 +$100 per head (m). Valves $300+$200 per 25mm of pipe size. Elbows $50+$50 per 25 mm of pipe size. Pipes $1 per 25 mm diameter per meter of length Table 2: Tank dimensions, pump and discharge point heights It (m) ht (m) bt (m) 0.01L 0 .20*T 0.50*lt Electricity cost $ 0.1 per kilowatt-hour. The plan is to design whole system through determining the optimum flow rate for each pipe diameter which yields maximum pump efficiency. For each diameter value, required pump power and the cost of whole system in a year should be calculated. It can be considered that this discharge system will be in operation twice in a day and the temperature of the water can be taken as 10C. Plot the below listed graphs in your reports: Group no:10 i. Head (m) - pipe diameter (m) ii. Power (kW) - pipe diameter (m) iii. 5-years total cost - pipe diameter (m). Page 1 DESIGN OF A PUMP PIPING SYSTEM Page 2 Choose the optimum pump from any product catalogue of a company and calculate i. The efficiency Your design task is to write a software in MATLAB for the design of sizing of the pipe and pump efficiency using a non-dimensional form. Each group will have different flow rates due the given dimensions of the reserve tank so that the input of the software will be the flow rates of the system. Each group should determine the optimum pipe diameter considering the required pump power, capital cost and yearly operating costs. The program will give plot of required pump power, pump efficiency, capital cost and yearly operating costs for each corresponding pipe diameter as an output. The flow chart of the design procedure should be clearly defined. ii. The Capacity Coefficient iii. The Head Coefficient iv. The Power Coefficient DEFINITION OF THE DESIGN REQUIREMENTS of your optimum pump. Definitions of the dimensions: L = Length of the piping system. It is desired to design a pump piping system to discharge a water reserve in a lake to a water distribution center in a city. The general piping and tank dimensions which are different in each group is given in Table 1. The geometric parameters of the tank which are given as a ratio of tank dimensions are presented in Table 2. The non-dimensional time (t*) required by the owner for the discharge is given as It = Length of the tank. bt = Beam of the tank. =tyg/h 10000 where t is given in seconds. The piping system has four regular 90 elbows and four gate valves and two swing checks. The galvanized type pipes will be used in the piping system where roughness of the pipe can be taken as E = 0.0003 * (group no +50) (m). The design should be economical both in capital cost and operation expenses. The cost estimates for the system components are given as ht = Height of tank from baseline to the top of double bottom. T = Height of discharge point from the lake and tank in distribution center. Table 1: Problem geomety dimensions of each group L (m) 1000 + Group No. 50 T(m) 5.00+ Group No 0.25 Pump and motor $3500 +$100 per head (m). Valves $300+$200 per 25mm of pipe size. Elbows $50+$50 per 25 mm of pipe size. Pipes $1 per 25 mm diameter per meter of length Table 2: Tank dimensions, pump and discharge point heights It (m) ht (m) bt (m) 0.01L 0 .20*T 0.50*lt Electricity cost $ 0.1 per kilowatt-hour. The plan is to design whole system through determining the optimum flow rate for each pipe diameter which yields maximum pump efficiency. For each diameter value, required pump power and the cost of whole system in a year should be calculated. It can be considered that this discharge system will be in operation twice in a day and the temperature of the water can be taken as 10C. Plot the below listed graphs in your reports: Group no:10 i. Head (m) - pipe diameter (m) ii. Power (kW) - pipe diameter (m) iii. 5-years total cost - pipe diameter (m)