A crossflow extraction system is being used to extract furfural from water into methyl-isobutyl ketone (MIBK) at

Question:

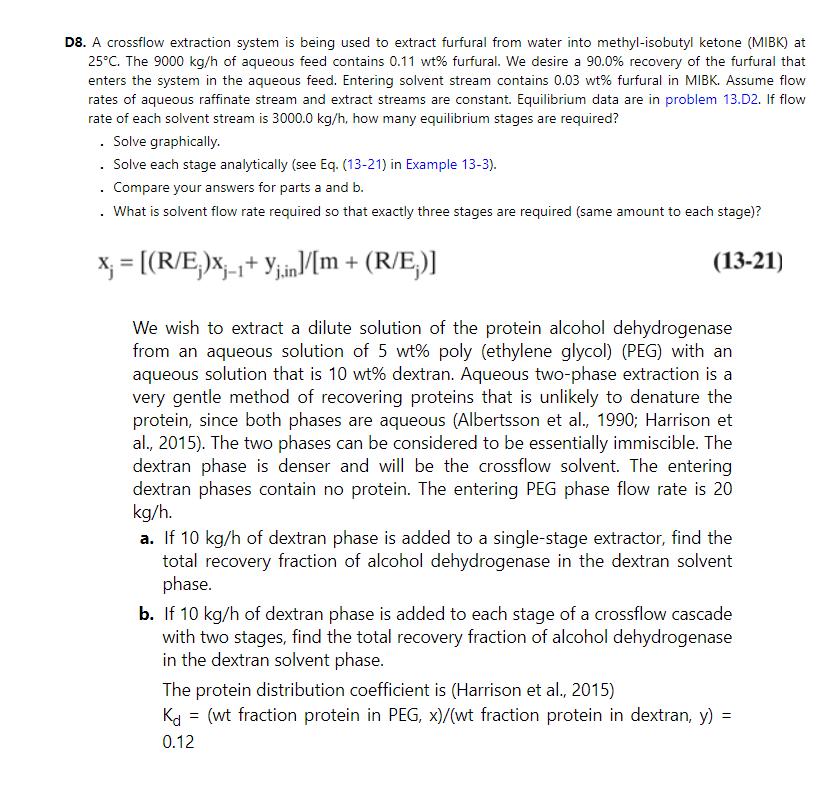

A crossflow extraction system is being used to extract furfural from water into methyl-isobutyl ketone (MIBK) at \(25^{\circ} \mathrm{C}\). The \(9000 \mathrm{~kg} / \mathrm{h}\) of aqueous feed contains \(0.11 \mathrm{wt} \%\) furfural. We desire a \(90.0 \%\) recovery of the furfural that enters the system in the aqueous feed. Entering solvent stream contains \(0.03 \mathrm{wt} \%\) furfural in MIBK. Assume flow rates of aqueous raffinate stream and extract streams are constant. Equilibrium data are in problem 13.D2. If flow rate of each solvent stream is \(3000.0 \mathrm{~kg} / \mathrm{h}\), how many equilibrium stages are required?

Data From Problem 13.D2

A countercurrent extraction system extracts furfural from water into methyl-isobutyl ketone (MIBK) at \(25^{\circ} \mathrm{C}\). Aqueous feed contains 0.0011 wt. fraction furfural and has a feed rate of \(9000 \mathrm{~kg} / \mathrm{h}\). Recovery of the furfural that enters in the aqueous feed is \(90.0 \%\). Entering solvent stream contains 0.0003 weight fraction furfural and remainder is MIBK. Assume flow rates of raffinate and extract streams are constant. Equilibrium data are \(\mathrm{K}_{\mathrm{d}}=7.1=(\mathrm{wt}\) frac furfural in MIBK \() /(\mathrm{wt}\). frac. furfural in water) (Perry and Green, 1984).

a. How many equilibrium stages are required for a solvent flow rate of \(1500.0 \mathrm{~kg} / \mathrm{h} ?\)

b. Compare the result in part a with solution to problem 13.D8.

c. What is minimum solvent flow rate?

Problem 13.D8

a. Solve graphically.

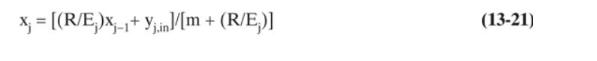

b. Solve each stage analytically (see Eq. (13-21) in Example 13-3).

Example 13-3

c. Compare your answers for parts \(a\) and \(b\).

d. What is solvent flow rate required so that exactly three stages are required (same amount to each stage)?

Step by Step Answer:

Separation Process Engineering Includes Mass Transfer Analysis

ISBN: 9780137468041

5th Edition

Authors: Phillip Wankat