A distillation column with a partial reboiler and a partial condenser is separating two feeds containing mixtures

Question:

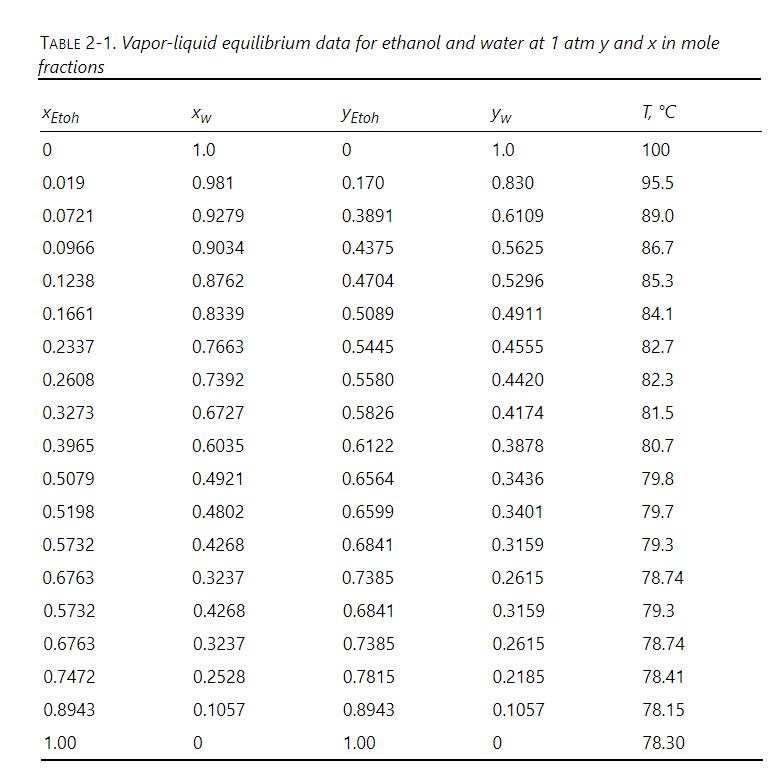

A distillation column with a partial reboiler and a partial condenser is separating two feeds containing mixtures of ethanol and water. Operation is at \(1.0 \mathrm{~atm}\) and CMO is valid. Feed A is \(40 \mathrm{~mol} \%\) ethanol, is a saturated vapor, and flow rate is \(200 \mathrm{kmol} / \mathrm{h}\). Feed B is \(30 \mathrm{~mol} \%\) ethanol, is a saturated liquid, and flow rate is 250 \(\mathrm{kmol} / \mathrm{h}\). Distillate has a mole fraction \(\mathrm{y}_{\mathrm{E}, \mathrm{D}}=0.7\), and bottoms mole fraction is \(\mathrm{x}_{\mathrm{E}, \mathrm{B}}\) \(=0.02\). VLE data are in Table 2-1.

a. Find the values of the distillate and bottoms flow rates.

b. What is the minimum reflux ratio \((\mathrm{L} / \mathrm{D})_{\min }\) ?

c. Use an actual reflux ratio \(\mathrm{L} / \mathrm{D}=2(\mathrm{~L} / \mathrm{D})_{\min }\), plot the operating lines, use the optimum feed stages, and find the total number of stages needed. Count stages from the top down, and list the locations of the optimum feed stages.

d. What is the value of \((\mathrm{s} / \mathrm{B})_{\min }\) ?

Step by Step Answer:

Separation Process Engineering Includes Mass Transfer Analysis

ISBN: 9780137468041

5th Edition

Authors: Phillip Wankat