We plan to distill (1100 mathrm{kmol} /) hour of a saturated vapor stream that is (16 mathrm{~mol}

Question:

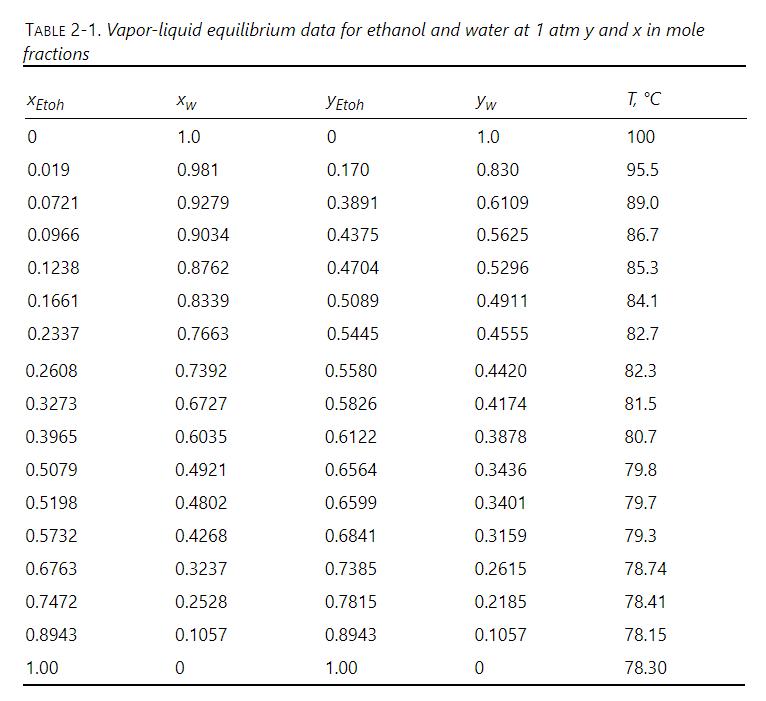

We plan to distill \(1100 \mathrm{kmol} /\) hour of a saturated vapor stream that is \(16 \mathrm{~mol} \%\) ethanol and \(84 \mathrm{~mol} \%\) water. The column has another feed that is \(900 \mathrm{kmol} /\) hour of a saturated liquid stream that is also \(16 \mathrm{~mol} \%\) ethanol and \(84 \mathrm{~mol} \%\) water. Both feed streams are sent to their optimum feed locations in the column. The column has a partial condenser and a partial reboiler and operates at \(1.0 \mathrm{~atm}\). We desire a vapor distillate with \(\mathrm{y}_{\mathrm{D}}=0.60\) mole fraction ethanol and a liquid bottoms with \(\mathrm{x}_{\mathrm{B}}\) \(=0.01\) mole fraction ethanol. Assume that CMO is valid. VLE data are in Table 2-1.

a. Find distillate flow rate \(\mathrm{D}\) and bottoms flow rate \(\mathrm{B}\).

b. If the boilup ratio \(r / B=1 / 3\), find the two optimum feed locations and the total number of stages required (step off stages from the bottom up).

Step by Step Answer:

Separation Process Engineering Includes Mass Transfer Analysis

ISBN: 9780137468041

5th Edition

Authors: Phillip Wankat