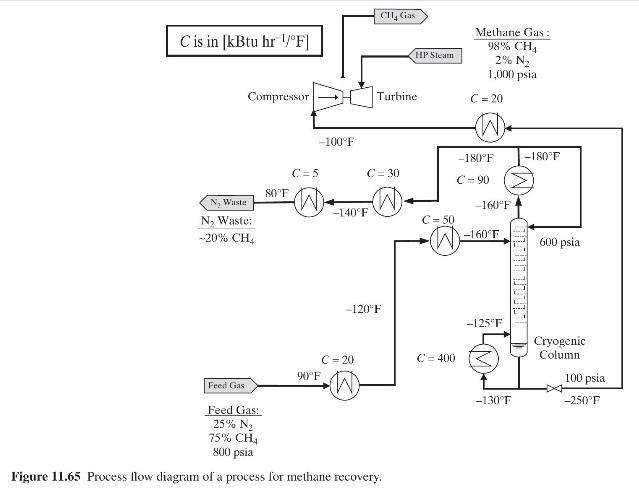

Figure 11.65 presents the PFD of a process for the recovery of methane from a feed stream

Question:

Figure 11.65 presents the PFD of a process for the recovery of methane from a feed stream consisting of \(75 \%\) methane and \(25 \%\) nitrogen. The process feed is first cooled from 90 to \(-160^{\circ} \mathrm{F}\), and because of partial condensation in the feed stream under these conditions, the stream is split into two portions as shown in the PFD: from 90 to \(-120^{\circ} \mathrm{F}\) where \(C=20 \mathrm{kBtu} / \mathrm{hr}{ }^{\circ} \mathrm{F}\) and from -120 to \(-150^{\circ} \mathrm{F}\) where \(C=50 \mathrm{kBtu} / \mathrm{hr}{ }^{\circ} \mathrm{F}\). After cooling, the feed is separated in the cryogenic column operating at \(600 \mathrm{psia}\). The column bottoms, rich in methane, are expanded to a pressure of \(100 \mathrm{psia}\), heated from -250 to \(-100^{\circ} \mathrm{F}\), and then fed to a compressor that raises its pressure to 1,000 psia. The column distillate heated from -180 to \(80^{\circ} \mathrm{F}\) also undergoes phase changes and, like the feed stream, is divided into two portions. Note that the design of the HEN for this process is limited to the usage of one type of cold utility and one type of hot utility.

(a) Compute MER targets for this process, at \(\Delta T_{\min }=10^{\circ} \mathrm{F}\).

(b) Design a HEN to meet the MER targets with the minimum number of units at \(\Delta T_{\text {min }}=10^{\circ} \mathrm{F}\) given that the design can utilize only one type of cold utility and one type of hot utility.

Step by Step Answer:

Product And Process Design Principles Synthesis Analysis And Evaluation

ISBN: 9781119355243

4th Edition

Authors: Warren D. Seider, Daniel R. Lewin, J. D. Seader, Soemantri Widagdo, Rafiqul Gani, Ka Ming Ng