Question:

In an ethanol plant, the mixture of water and ethanol from the beer column distillate contains about 40% ethanol (molar basis) in water, together with the fusel oils described in the previous problem. This mixture is distilled to give an azeotropic mixture of ethanol and water (89% ethanol) overhead, with 99.9% recovery of ethanol. The fusel oil can cause blending problems if it is allowed to accumulate in the distillate. Fusel oil is a mixture of higher alcohols and ethers that can be approximated as a mixture of n-butanol and diethyl ether. This mixture is usually removed as a side stream from the column. When the side stream is contacted with additional water a two-phase mixture can be formed and the oil phase can be decanted to leave an ethanol-water phase that is returned to the column.

1. Draw a flowsheet for this process.

2. Estimate the stream flow rates and compositions for a production rate of 200,000 US gal/d of dry (100%) ethanol.

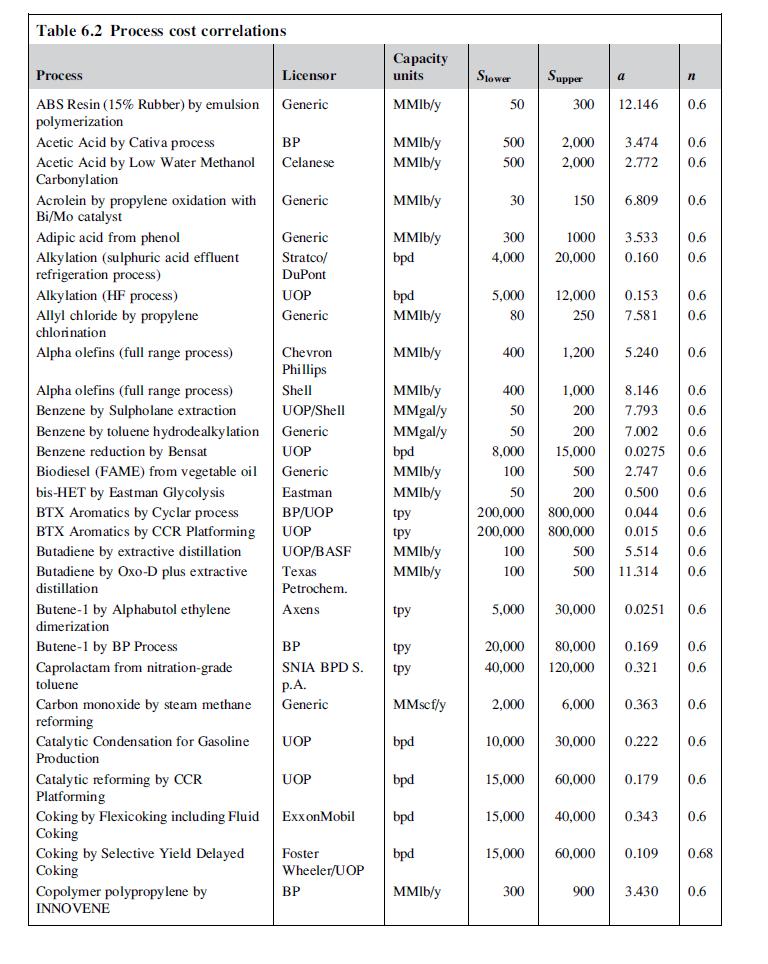

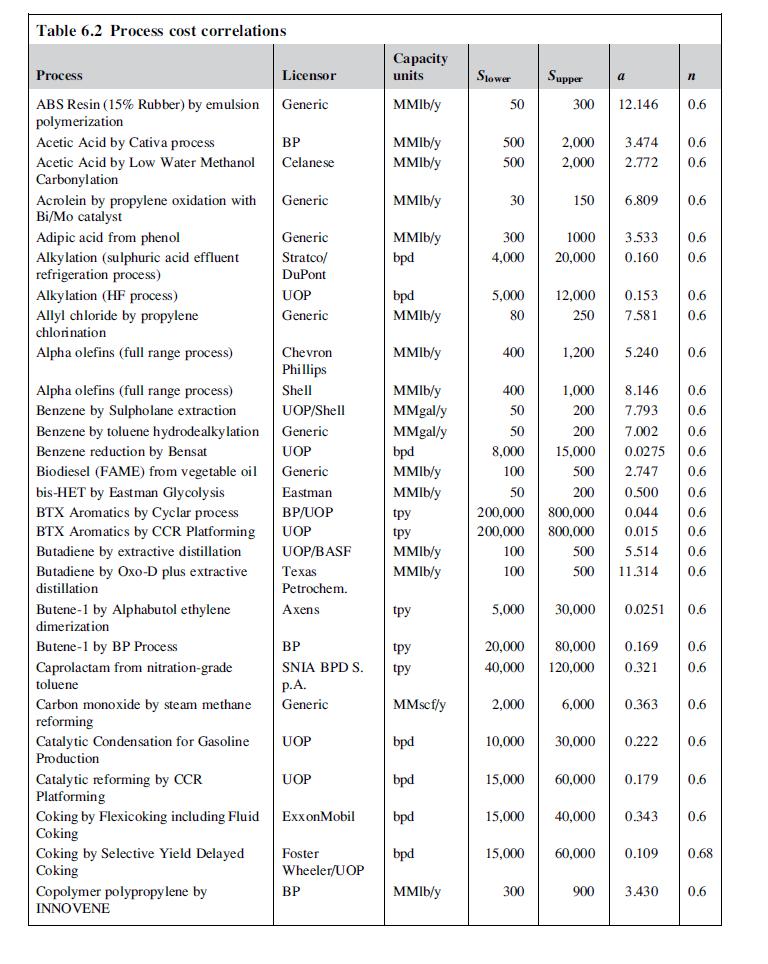

3. Optimize the distillation column using the cost correlations given in Section 6.3 and assuming that reboiler heat costs $5/MMBtu. Minimize the total annualized cost of the column.

Data from section 6.3

Transcribed Image Text:

Table 6.2 Process cost correlations.

Process

ABS Resin (15% Rubber) by emulsion

polymerization

Acetic Acid by Cativa process

Acetic Acid by Low Water Methanol

Carbonylation

Acrolein by propylene oxidation with

Bi/Mo catalyst

Adipic acid from phenol.

Alky lation (sulphuric acid effluent

refrigeration process)

Alkylation (HF process)

Allyl chloride by propylene

chlorination

Alpha olefins (full range process)

Alpha olefins (full range process)

Benzene by Sulpholane extraction

Benzene by toluene hydrodealkylation

Benzene reduction by Bensat

Biodiesel (FAME) from vegetable oil

bis-HET by Eastman Glycolysis

BTX Aromatics by Cyclar process

BTX Aromatics by CCR Platforming

Butadiene by extractive distillation

Butadiene by Oxo-D plus extractive

distillation

Butene-1 by Alphabutol ethylene

dimerization

Butene-1 by BP Process

Caprolactam from nitration-grade

toluene

Carbon monoxide by steam methane

reforming

Catalytic Condensation for Gasoline

Production

Catalytic reforming by CCR

Platforming

Coking by Flexicoking including Fluid

Coking

Coking by Selective Yield Delayed

Coking

Copolymer polypropylene by

INNOVENE

Licensor

Generic

BP

Celanese

Generic

Generic

Stratco/

DuPont

UOP

Generic

Chevron

Phillips

Shell

UOP/Shell

Generic

UOP

Generic

Eastman

BP/UOP

UOP

UOP/BASF

Texas

Petrochem.

Axens

BP

SNIA BPD S.

p.A.

Generic

UOP

UOP

Foster

Wheeler/UOP

Capacity

units

MMIb/y

BP

MMIb/y

MMIb/y

MMlb/y

MMIb/y

bpd

bpd

MMlb/y

MMIb/y

MMIb/y

MMgal/y

MMgal/y

bpd

MMlb/y

MMIb/y

tpy

tpy

MMIb/y

MMIb/y

tpy

bpd

bpd

ExxonMobil bpd

bpd

tpy

tpy

MMscf/y

MMIb/y

Slower Supper

50

500

500

30

300

4,000

400

400

50

50

8,000

100

50

5,000 12,000

80

250

20,000

40,000

2,000

10,000

300

15,000

150

15,000

2,000 3.474 0.6

2,000 2.772 0.6

200,000 800,000

200,000 800,000

100

100

300

20,000

5,000 30,000

1000 3.533

0.160

1,200

1,000

200

200

15,000

500

200

a

12.146 0.6

30,000

6.809 0.6

60,000

8.146

0.6

7.793

0.6

7.002

0.6

0.0275 0.6

2.747 0.6

0.500 0.6

0.044 0.6

0.015 0.6

500

5.514

0.6

500 11.314 0.6

0.153

7.581

60,000

5.240

80,000 0.169 0.6

120,000

0.321

0.6

6,000 0.363 0.6

0.6

0.6

0.0251 0.6

0.222

0.6

0.6

0.179

0.6

0.109

15,000 40,000 0.343 0.6

900 3.430

0.6

0.6

0.68

0.6