Question: In Example 11.13, HENs are designed for a process involving two hot and two cold streams. Note that three designs are proposed: (1) involving only

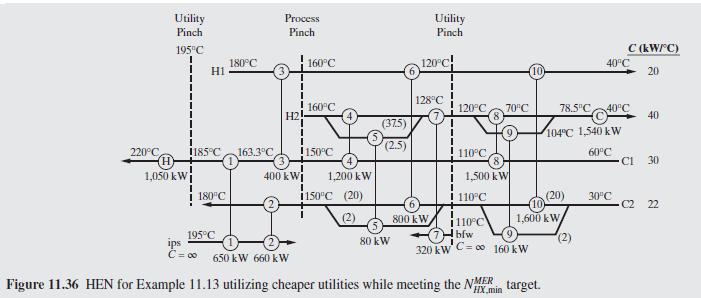

In Example 11.13, HENs are designed for a process involving two hot and two cold streams. Note that three designs are proposed: (1) involving only HP steam and cooling water that meets the \(N_{H X, \min }^{M E R}\) target; (2) involving HP steam and cooling water with no stream splitting and one less heat exchanger and (3) utilizing HP and IP steam, cooling water, and boiler feed water. Which of these designs has the lowest annualized cost given the following specifications?

Data From Example 11.13:-

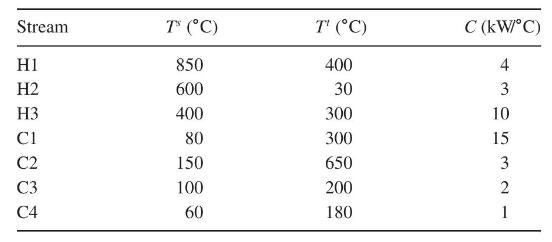

----A HEN is to be designed to meet MER targets for the following stream data:

(a) Compute MER targets for this process at \(\Delta T_{\text {min }}=10^{\circ} \mathrm{C}\).

(b) Design a HEN to meet the MER targets at \(\Delta T_{\min }=20^{\circ} \mathrm{C}\) with no more than 10 heat exchangers (including utility heaters and coolers).

(c) Draw the GCC for this process and use it to suggest changes to the HEN to reduce operating costs. In so doing, note that there are no restrictions in the number of units.

Cooling water (cw): \(T^{s}=30^{\circ} \mathrm{C}, T^{t} \leq 80^{\circ} \mathrm{C}\), cost of \(c w=0.00015 \$ / \mathrm{Kg}\)

Boiler feed water (bfw): \(T=110^{\circ} \mathrm{C}, \Delta H^{v}=2,230 \mathrm{~kJ} / \mathrm{kg}\), revenue on bfw \(=0.001 \$ / \mathrm{kg}\)

IP Steam (sat'd, ips): \(T=195^{\circ} \mathrm{C}, \Delta H^{v}=1,958 \mathrm{~kJ} / \mathrm{kg}\), cost of ips \(=0.003 \$ / \mathrm{kg}\)

HP Steam (sat'd, \(h p s\) ): \(T=258^{\circ} \mathrm{C}, \Delta H^{v}=1,676 \mathrm{~kJ} / \mathrm{kg}\), cost of \(h p s=0.006 \$ / \mathrm{kg}\)

Overall heat-transfer coefficients: \(U_{\text {heater }}=U_{\text {cooler }}=U_{\text {exch }}=\) \(1 \mathrm{~kW} / \mathrm{m}^{2}{ }^{\circ} \mathrm{C}\)

Purchase cost of heat exchangers: \(C_{P}=3,000 A^{0.5}\left(\$, \mathrm{~m}^{2}\right)\)

Return on investment, \(i_{m}=0.1\).

Bonus: Adapt the design in Figure 11.36 to produce a cheaper HEN.

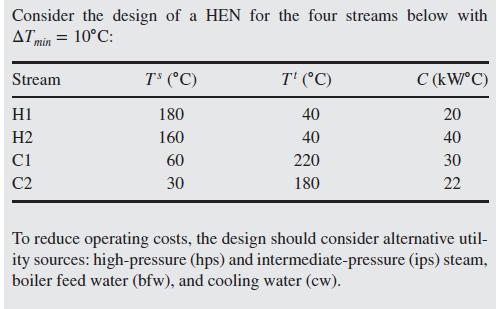

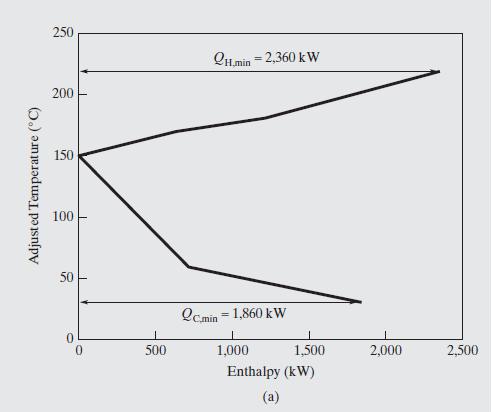

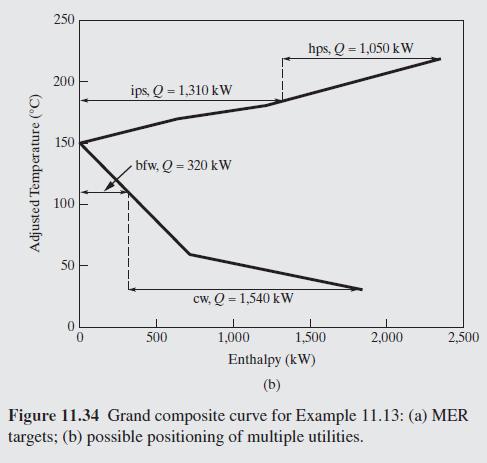

Consider the design of a HEN for the four streams below with ATmin = 10C: Stream T (C) T' (C) C (kW/C) H1 180 40 20 H2 160 40 40 C1 60 220 30 C2 30 180 22 To reduce operating costs, the design should consider alternative util- ity sources: high-pressure (hps) and intermediate-pressure (ips) steam, boiler feed water (bfw), and cooling water (cw).

Step by Step Solution

3.38 Rating (151 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts