Moss Manufacturing has just completed a major change in the method it uses to inspect its product.

Question:

Moss Manufacturing has just completed a major change in the method it uses to inspect its product. Previously 10 inspectors examined the product after each major process. The salaries of these inspectors were charged as direct labor to the operation or job. In an effort to improve efficiency, the Moss production manager recently bought a computerized quality control system consisting of a microcomputer, 15 video cameras, peripheral hardware, and software. The cameras are placed at key points in the production process, taking pictures of the product and comparing these pictures with a known "good" image supplied by a quality control engineer. This new system allowed Moss to replace the 10 quality control inspectors with only two quality control engineers.

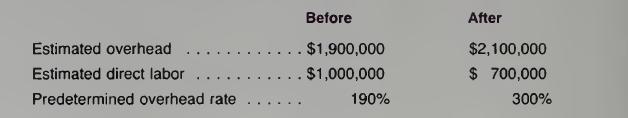

The president of the company is concerned. She was told that the production process was now more efficient, yet she notices a large increase in the factory overhead rate. The computation of the rate before and after automation is as follows:

How might an activity-based costing system benefit Moss Manufacturing and clear up the president's confusion?

Step by Step Answer: