(CMA) Process costing with normal and abnormal spoilage Ranka Company manufac- tures high-quality leather products. The company's...

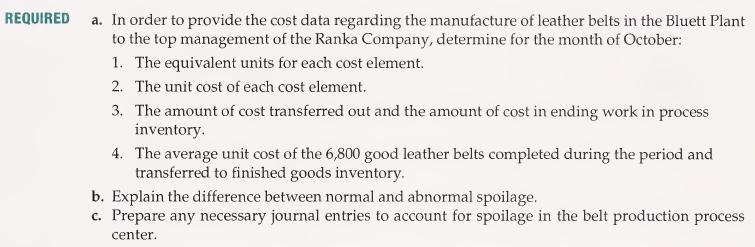

Question:

(CMA) Process costing with normal and abnormal spoilage Ranka Company manufac- tures high-quality leather products. The company's profits have declined during the last five months. Ranka has used unit cost data that were developed eighteen months ago in planning and controlling its operations. In an attempt to isolate the causes of poor profit performance, manage- ment is investigating the manufacturing operations of each of its products.

One of Ranka's main products is fine leather belts. The belts are produced in a single, continuous flow production process in the Bluett Plant. During the process, leather strips are sewn, punched, and dyed. Buckles are attached by rivets when the belts are 70% complete as to direct labor and overhead (conversion costs). The belts then enter a final finishing stage to conclude the process. Labor and overhead are applied continuously during the process.

The leather belts are inspected twice during production: (1) right before the buckles are attached (70% point in the production process), and (2) at the conclusion of the finishing stage (100% point in the production process). Ranka uses the weighted average method to calculate its unit costs.

The leather belts produced at the Bluett Plant wholesale for $9.95 each. Management wants to compare the current manufacturing costs per unit with the prices that exist on the market for leather belts. Top management has asked the Bluett Plant to submit data on the costs of manufac- turing the leather belts for the month of October. These cost data will be used to evaluate whether modifications in the production process should be initiated or whether an increase in the selling price of the belts is justified. The cost per equivalent unit that is being used for planning and controlling purposes is $5.35 per unit.

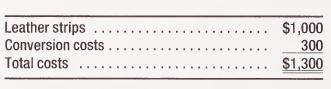

The work in process inventory consisted of 400 partially completed units on October 1. The belts were 25% complete as to conversion costs. The costs included in inventory on October 1 were as follows:

During October, 7,600 leather strips were placed into production. A total of 6,800 good leather belts were completed. A total of 300 units were identified as defective at the two inspection points; 100 at the first inspection point (before the buckle is attached) and 200 at the final inspection point (after finishing). This quantity of defective belts is considered normal. In addition, 200 belts were removed from the production line when the process was 40% complete as to conversion costs because they had been damaged as a result of a malfunction during the sewing operation. This malfunction was considered an unusual occurrence, and consequently, the spoilage was classi- fied as abnormal. Defective (spoiled) units are not reprocessed and have zero salvage value. The work in process inventory as of October 31 consisted of 700 belts that were 50% complete as to conversion costs.

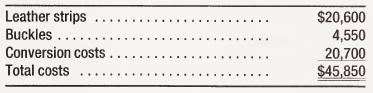

The costs charged to production during October were as follows:

Step by Step Answer: