Normal and abnormal spoiled units The management of the Winsloe Company has a pol- icy of carefully

Question:

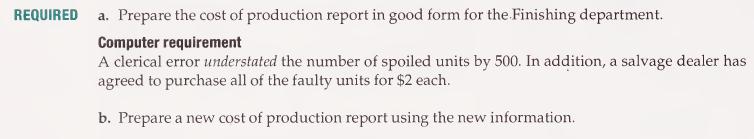

Normal and abnormal spoiled units The management of the Winsloe Company has a pol- icy of carefully monitoring production quality and the cost of unacceptable production. The company's main product is boat compasses manufactured in a process costing environment. In the final process center. Finishing, units are sealed, painted, buffed, and packaged. The main assembly, transferred in from the preceding process center, is tested for accuracy before any material is added or conversion is done in Finishing. Unacceptable units are discarded because the cost of correcting them is prohibitive. The management of Winsloe is very proud of its quality control and the management of its manufacturing activities. Although some spoilage is expected the amount is relatively small. Normal spoilage does not exceed 5% of the units transferred in during the month.

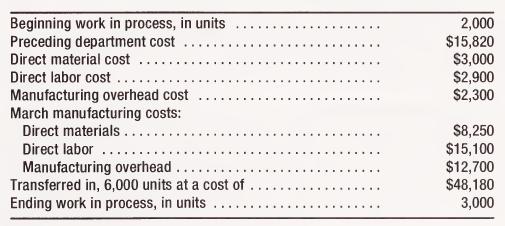

March production data for Finishing are presented below:

Both beginning and ending work in process have all materials and 50% conversion. The weighted average inventory method is used. 500 units are lost at the beginning of production in Finishing before any material is added or conversion takes place. A separate spoiled unit cost is used.

Step by Step Answer: