Revisions of Standards: Lenco Company employs a traditional standard cost system as part of its cost control

Question:

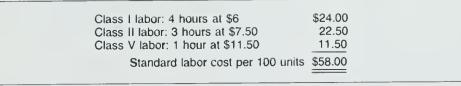

Revisions of Standards: Lenco Company employs a traditional standard cost system as part of its cost control program. The standard cost per unit is established at the beginning of each year. Any revisions in standards are deferred until the beginning of the next fiscal year. However, to recognize changes in standards in the current year, the company includes "planned" variances in the monthly budgets prepared after such changes have been introduced. The following labor standard was set for one of Lenco's products effective July 1. the beginning of the fiscal year.

The standard was based on the quality of material used in prior years and that expected for the current fiscal year. Labor activity is performed by a team consisting of four persons with Class I skills, three persons with Class II skills, and one person with Class V skills. This is the most economical combination. Manufacturing operations occured as expected during the first five months of the year. However, the company received a significant increase in orders for delivery in the spring. There was an inadequate number of skilled workers available to meet the increased production. As a result, the production teams, beginning in January, were made up of more Class I labor and less Class 11 labor than the standard specified. The teams would consist of six Class I persons, two Class II persons, and one Class V person. This labor team is less efficient than the normal team. As a result, only 90 units are produced in the same time period that 100 units would normally be produced. No changes in direct materials used per unit of output will occur because of the change in the labor mix. Lenco was notified by its materials supplier that a lower quality material would be supplied after January 1. however. One unit of direct material normally is required for each good unit produced. Lenco and its supplier estimate that 5 percent of the units manufactured would be rejected upon final inspection due to the lower quality material. Normally, no units are lost due to defective material.

Required:

a. How much of the lower quality material must be entered into production to produce 42,750 units of good production in January with the new labor teams? Show your calculations.

b. How many hours of each class of labor will be needed to produce 42,750 good units from the material input? Show your calculations.

c. What amount should be included in the January budget for the planned labor variance due to the labor team and material changes? What amount of this planned labor variance can be associated with the ( 1 ) material change and (2) the team change? Show your calculations.

Step by Step Answer: