Easy Sweep makes vacuum cleaners for both residential and commercial customers. It has been making vacuum cleaners

Question:

Easy Sweep makes vacuum cleaners for both residential and commercial customers. It has been making vacuum cleaners for more than 50 years, starting with one small model that was sold door-to-door. It is now a multibillion- dollar producer of high-end vacuum cleaners using an international distribution network of retail outlets and specialty shops.

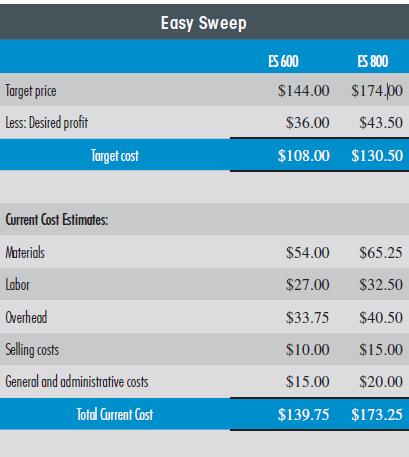

Easy Sweep’s management has recently decided to enter the market for bagless vacuum cleaners and has designed a product that meets the company ’s high-quality image. They plan to produce two models, the ES 600 and the ES 800. The ES 600 will retail at $240, while the commercial-grade ES 800 will retail at $290. The company sells its vacuums to the distribution channel at roughly 60% of the retail price, making the target price for the ES 600 model $144, while the target price for the ES 800 model is $174. The company likes to make a 25% profit on all of its models. The resulting target cost and current estimated costs for producing the two vacuum models are in the table below.

Seeing that the current costs consume almost all of the company ’s selling price, Lisa Adams, V P of manufacturing, calls together the design team. Some of the comment s made at the meeting are:

Lisa: We’ve got a real problem with these first-pass estimates. We would barely make a profit with these costs the way they are. We’ve got to cut somewhere. The question is where.

Paul Gable, design engineer: Lisa, I don’t know how we can take much out of the cost unless we outsource the making of the drive engine. That’s the most expensive part and it uses components that are unique to these vacuums. I got a quote, and we could reduce the cost of materials by $10 per model if we outsource it. That would also reduce labor by $5 and overhead by the 125% of labor that we use for our plant-wide rate. I don’t know what we can do with the other overhead here, which is where an awful lot of the cost is going.

Lisa: If I get your numbers right, we could eliminate $15 in direct cost and $6.25 in manufacturing overhead if we outsource the drive engine. That gets us $21.25 closer to our target cost, closing the gap to $10.50 for the ES 600 and $21.50 for the ES 600. I still don’t think management will be happy with these results.

Mark Eaton, marketing VP: I’m not happy with the thought of outsourcing a key part of the vacuum. Won’t we lose control of quality and open ourselves up to potential problems in the market? We’re known for our quality. How can we guarantee this?

Paul: We have done a lot of work in the past with this supplier. We would clearly need to do more inspection, which would drive costs back up by $3 per unit, so our cost gaps would likely be $13.50 and $24.50 respectively. With more inspections, we can guarantee quality. Also, our design team will spend significant time working with the supplier.

Lisa: Wait a minute. We already have a missing charge for development in cost estimate, don’t we? And you want to add the amount of time and effort that goes into design to outsource the unit. Why can’t that time be spent making internal design changes to get us in line with the outsourced unit? We try not to outsource here at Easy Sweep. I’d hate to see us start down that path because no matter how well we inspect, we lose control over the component if it isn’t made here. And who’s to say that once we outsource the drive engine, the supplier won’t raise prices?

Paul: We can estimate that design work will cost on average $5 per unit if we outsource the drive engine and $6 a unit if we do it internally. That cost would apply to the first 100,000 units of each product made if you want to recoup the development cost in the unit cost. I agree we could get the cost of the drive engine down by $15 in materials and $5 in labor, with a reduction of 125% of labor in our overhead charge if we really work the design. Where does that leave us now?

Lisa: Hmmm….Down $20 but back up $6, so we’d be closing the cost gap by $14 if we make the part internally, in keeping with company policy. T hat would make our new cost gap for the ES 600 $14.75 and $28.75 for the ES 800. I can’t do that overhead calculation in my head, but that ’s got to be another $6 or so in savings, right? Even so, the cost gap is still too big.

Mark: I think we could cut the marketing costs by 30% if that would help. We have the distribution channel in place. My question is why is general company overhead so high? What is the back office really adding to their work load when we’re using existing customers and channels? They may have to do a few more purchase orders and invoices, but not to the tune of $15 and $20 per unit. That’s a lot of money on the projected 100,000 unit sales planned for this year. Can’t we reduce these by 40%?

Lisa: Both the general overhead and the manufacturing overhead were estimates based on current charges for other models. I bet we could get some money out there as we’re going to be using cellular manufacturing, which is much more efficient . We could probably cut manufacturing overhead by 25%. Tell you what , I’ll put all of these suggestions together and see how close we get . We may have to find a few more savings, but we’re making progress.

REQUIRED:

a. Use the final changes in estimates suggested by Mark and Lisa to develop a new estimate of the cost gap. How much further do they need to go to make the product hit its profit goals?

b. Does it seem reasonable to use new costing assumptions for the new models or do you think the entire system of overhead charges should be examined to determine exactly how much of the overhead costs for manufacturing and general overhead should be charged to the new vs. existing units?

c. How do you feel about the outsourcing option? Do you feel Mark is right to worry about the quality risk; or do you think that outsourcing might be a better option? Why or why not?

Step by Step Answer:

Managerial Accounting An Integrative Approach

ISBN: 9780999500491

2nd Edition

Authors: C J Mcnair Connoly, Kenneth Merchant