Question:

In a biofuels plant distillation tower, a single-pass shell- and-tube heat exchanger is used to condense saturated ethanol vapor to saturated ethanol liquid using water as the tube-side cooling fluid. The process is carried out at 1 atm total system pressure. The ethanol vapor flow rate into the shell side of the condenser is 2 kg/s. Cooling water is available at 20°C, and the maximum allowable exit temperature of the cooling water is 5 0°C.

a. What is the mass flow rate of cooling water required?

b. What is the log-mean temperature driving force in the condenser?

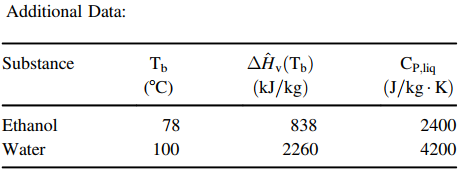

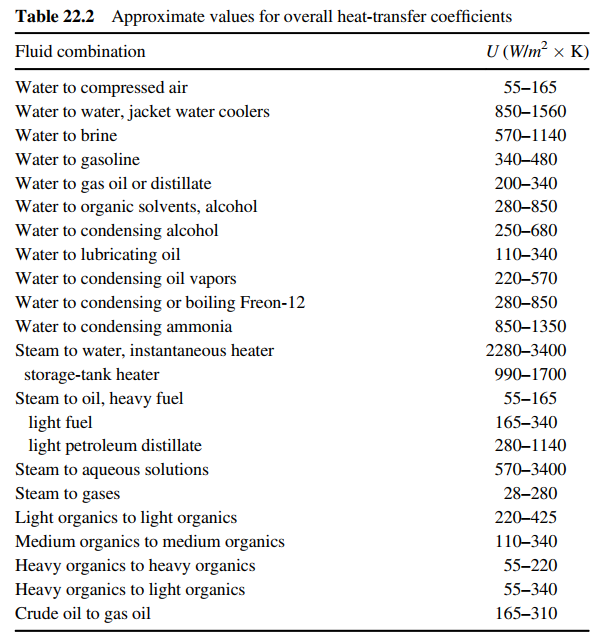

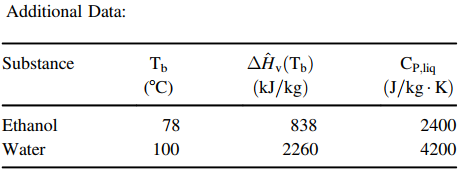

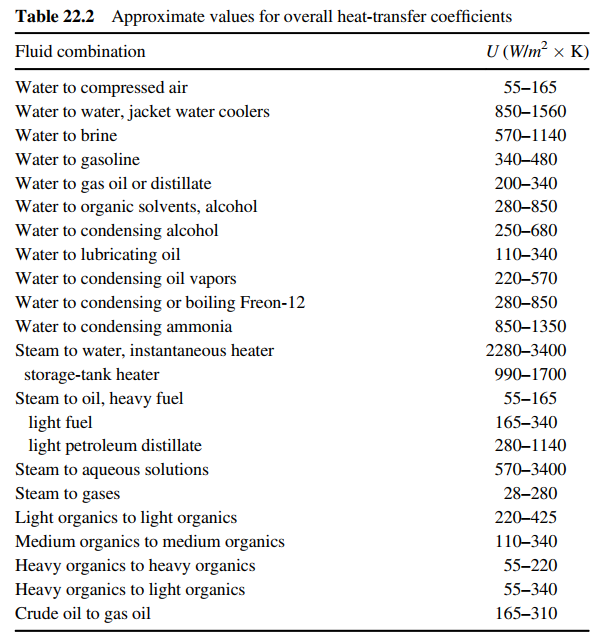

c. If the overall heat-transfer coefficient is 250 W/m2 · K (Table 22.2), what is the required heat-transfer area?

d. If the cooling water outlet temperature is allowed to increase by stepping down the cooling water flow rate, what happens to the required heat-transfer area?

Transcribed Image Text:

Additional Data: Substance ΔΗΗ (T ) (kJ/kg) Ть (°C) Cp,jiq (J/kg · K) Ethanol Water 838 2400 4200 78 100 2260 Table 22.2 Approximate values for overall heat-transfer coefficients Fluid combination U (W/m x K) Water to compressed air 55–165 Water to water, jacket water coolers 850–1560 Water to brine 570–1140 Water to gasoline 340-480 Water to gas oil or distillate Water to organic solvents, alcohol Water to condensing alcohol Water to lubricating oil Water to condensing oil vapors 200–340 280-850 250–680 110–340 220-570 Water to condensing or boiling Freon-12 Water to condensing ammonia 280–850 850–1350 Steam to water, instantaneous heater 2280–3400 storage-tank heater Steam to oil, heavy fuel 990–1700 55-165 light fuel light petroleum distillate Steam to aqueous solutions Steam to gases 165–340 280–1140 570–3400 28–280 220–425 Light organics to light organics Medium organics to medium organics 110–340 Heavy organics to heavy organics Heavy organics to light organics Crude oil to gas oil 55-220 55-340 165–310