Chief executive officer of Autoliv Inc., Jan Carlson, is in the middle of a board of directors

Question:

Chief executive officer of Autoliv Inc., Jan Carlson, is in the middle of a board of directors’ meeting in Stockholm in December 2014, discussing how to further globalize Autoliv. He takes out a situation report for the business area of airbags. As there are a couple of new members on the board, Carlson takes the opportunity to give a broader introduction to the business area than he usually does. The following is his status report.

Situation report for the business area of airbags

Business concept

Autoliv Inc., which is a Fortune 500 company, is the world’s largest automotive safety supplier with sales to all the leading car manufacturers in the world.

Autoliv’s shares are listed on the New York Stock Exchange and on the Stockholm Stock Exchange. The company develops, markets and manufactures airbags, seat belts, safety electronics, steering wheels, anti-whiplash systems, seat components and child seats. Autoliv has 80 subsidiaries (production plants)

and joint ventures in 30 vehicle-producing countries, with around 34,000 employees. In addition, Autoliv has technical centres in nine countries with 20 crash test tracks – more than any other automotive safety supplier.

Autoliv aims to develop, manufacture and market systems and components worldwide for personal safety in automobiles. This includes the mitigation of injuries to automobile occupants and pedestrians and the avoidance of accidents. Autoliv wants to be the systems supplier and the development partner to car producers that satisfies all the needs in the area of personal safety. To fulfil its business concept, Autoliv has strong product lines:

• Frontal and side-impact airbags (including all key components such as inflators with initiators, textile cushions, electronics with sensors and software, steel and plastic parts)

• Seat belts (including all key components such as webbing, retractors and buckles)

• Seat belt features (including pre-tensioners, load limiters, height adjusters and belt grabbers)

• Seat subsystems (including anti-whiplash systems)

• Steering wheels (including integrated driver airbags)

• Roll-over protection (including sensors, pre-tensioners and airbag curtains)

• Night-vision system with pedestrian detection and warning (this product was introduced in BMW cars in 2008).

Autoliv’s short- and medium-range radar system provides all-weather object detection and tracking to improve safety and to provide assistance to the driver. The radar can be used for blind spot detection, lane change assist, adaptive cruise control, collision mitigation by braking and for back-up and park assist functions. The radar could also provide front and side pre-crash sensing that scans up to 30 metres around the vehicle to provide an advanced warning of an imminent collision. This additional time could be used to prime airbags and active seat belts. (An active seat belt has an electrically driven pre-tensioner that tightens the belt as a precaution in hazardous situations.)

Autoliv already delivers active seat belts to four premium-brand vehicle models for three different customers.

In 2014, the penetration rate of frontal and side airbags in Europe was nearly 100 per cent. For curtain airbags in new cars, the penetration rate was 80 per cent in Europe, 60 per cent in North America, 45 per cent in Japan and 35 per cent in the rest of the world.

The following concentrates on the business area of airbags.

Production strategy

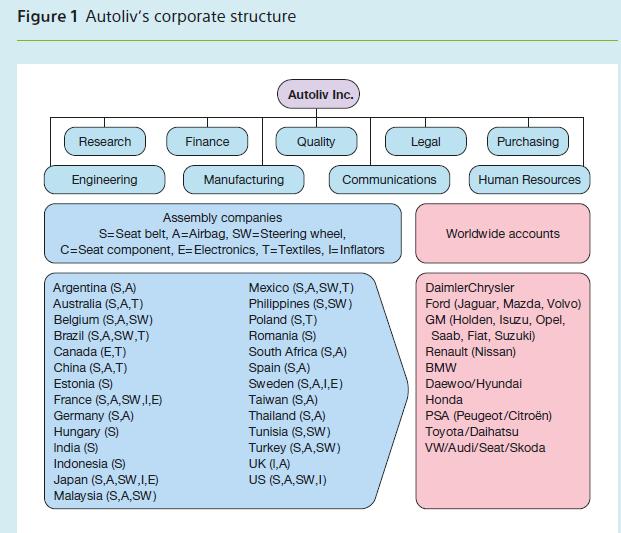

Autoliv has final assembly of restraint systems, located close to major customers’ plants for just-in-time supply (see Figure 1). Most of the component production (textiles and stamped metal components, etc.) has been outsourced since 2009.

Since major automobile manufacturers are continually expanding production into more countries, it is also Autoliv’s strategy to have manufacturing capacity where the major vehicle manufacturers have or are likely to set up production facilities. As a consequence,

Autoliv has more plants for automotive safety products in more countries than any other supplier.

The product: the airbag

Even the best belt designs cannot prevent all head and chest injuries in serious head-on crashes. This is where airbags help, by creating an energy-absorbing cushion between an occupant’s upper body and the steering wheel, instrument panel or windshield. Independent research has shown that driver deaths in head-on crashes are about 20 per cent lower in cars with frontal airbags than in similar cars with belts only. In all kinds of crashes, deaths are down by about 15 per cent over and above lives already being saved by belts.

Although airbags may seem complicated, they are in fact relatively simple. In moderate and severe head-on crashes, sensors signal inflators to fill the bags with harmless gas. The bags fill in a fraction of a second and begin deflating the instant they cushion people. Peak inflation occurs in less than one-twentieth of a second, faster than the blink of an eye.

The speed and force of airbag inflation may occasionally cause injuries, mostly minor abrasions or bruises, but in the US some occupants have died from broken necks caused by airbags that inflated with great force.

Those at the greatest risk of injury caused by an airbag are those who drive or ride unbelted, small children, short or obese adults, and certain disabled people.

Injury risk from the bag itself can be reduced by choosing a driving or passenger position that does not put your face or chest close to the steering wheel or instrument panel. The combination of seat belt and airbag provides maximum protection in all kinds of crash.

Together with Volvo, Autoliv has also developed the first side airbags to protect drivers and front-seat passengers in side-impact crashes. These bags are typically smaller than frontal airbags and they inflate more quickly. Volvo was the first manufacturer to offer side airbags in its 850 model in 1994. Volvo’s bag is mounted on the outside of the driver and front-seat passenger’s seat backs. Since 1996, side bags have been standard in all Volvo models.

The history of airbags goes back to the early 1950s.

The product idea was patented in 1951 by Walter Linderer from Munich. It was in the US, however, that the concept came into existence, driven by the North Americans’ reluctance to use seat belts and hindered by the car manufacturers, who initially ridiculed the idea. In 1981, only 2,636 airbag systems were produced.

However, in late 1989 automatic restraint systems became compulsory in all passenger cars in the US on the driver’s side and, while this included automatically fastening seat belts, it seemed that the airbag had at last arrived. By 1992, 10 million airbag-equipped cars had been delivered to the US. In 1993 came the requirement that all new light vehicles of model year 1999 produced in the US had to be fitted with frontal airbags for the driver and the front-seat occupant. The next stage will be the compulsory fitting of airbags to both the driver and front passenger sides.

Autoliv introduced its first airbag system in 1990.

It was designed to meet US requirements, where not all states have laws on wearing seat belts. The airbag therefore had to be relatively large. Autoliv has developed a special system (the Eurobag system) for markets where wearing a seat belt is compulsory. In this system, the airbags are of smaller volume (but they are still effective) and therefore the price can be kept at a lower level than some of the competitors. In the Eurobag system, the airbags are 30–45 litres on the driver’s side and 60–100 litres on the passenger’s side. Furthermore, the Eurobag system is lighter and less bulky.

An airbag system consists of an electronic control unit and an airbag module. The electronic control unit contains (among other things) a sensor, while the module essentially consists of a gas generator, a nylon bag and a cover for the steering wheel centre or the instrument panel, depending on where the airbag module is placed. Autoliv typically supplies entire systems adapted to individual car models......

Questions

1. Describe Autoliv’s role as a subsupplier for large car manufacturers in a market that is characterized by consolidation.

2. Which car manufacturer should Autoliv target to strengthen its global competitive position?

3. What strategic alternative does Autoliv have to strengthen its competitive position outside Europe?

Step by Step Answer: