Costing and impact of denominator values A small manufacturing company operates plant which runs on a five

Question:

Costing and impact of denominator values A small manufacturing company operates plant which runs on a five days per week basis. It operates a single shift of 8 hours per day. The company has periods of planned closure, when no production occurs, of 16 working days for each year. All of the remaining days the plant is available for production apart from planned maintenance which is anticipated to occupy 180 hours per year.

The marketing department has made projections of the next five years’ sales and these are expected to average out at a requirement for 1,500 machine hours per year.

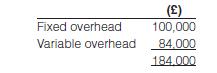

In the year immediately ahead 1,400 hours of machine time have been budgeted to meet anticipated production requirements. Based on the annual budgeted production volume of 1,400 hours for the following year the budgeted overhead costs are:

Required:

(a) Calculate three different hourly overhead recovery rates which demonstrate the use of:

(i) practical capacity (ii) long-run expected volume (iii) annual budgeted volume.

(b) Explain the implications of the different volumes in

(a) above, on the:

(i) overhead recovery rates (ii) product costs (iii) volume variances produced by the company.

(c) If the company adopted the ‘practical capacity’ as a basis for overhead rates, discuss how they might interpret and use, for strategic purposes, the costs and volume variances which may emerge.

For calculations work on the basis of 1 year = 52 weeks.

Step by Step Answer:

Management Accounting For Business

ISBN: 9781138550650

8th Edition

Authors: Colin Drury, Mike Tayles