Forest Industries Paper Company (FIPC) was a small, closely held paperboard manufacturer that produced a broad line

Question:

Forest Industries Paper Company (FIPC) was a small, closely held paperboard manufacturer that produced a broad line of paperboard in large reels, termed parent rolls. These parent rolls were sold to converters who further processed them into containers used for a variety

*Case prepared by Dr. Thomas Albright for use in the Institute of Management Accountant's Regional Education Assistance Program (REAP) course in Strategic Cost Management. Used with permission.

of consumer products. The owners of FIPC had long pursued the strategy of producing a full range of products. While product diversity within a paperboard plant would not readily be apparent to the casual observer, subtle differences existed. For example, paperboard differs by basis weight (or thickness determined by caliper measurements) for a specified length of product.

FIPC produced 20 different grades of paperboard. Some were produced in large quantities requiring production runs of several days, while others were produced in smaller quantities requiring runs of only a few hours.

Pulp manufacturing begins with hardwood or softwood timber in the form of wood chips. The second step in the process is termed "digesting." Wood chips are cooked at 325 degrees Fahrenheit to break down the glue-like material bonding the wood fibers. Following the digesting process, brown fibers are washed and screened. A bleaching process is used to convert brown pulp into white pulp.

The paperboard manufacturing process begins by mixing pulp with water and chemicals in the first stage of a paper machine. The mixture is applied to a porous wire mesh; formation of paper actually occurs within this step. The wire mesh travels through a press that forces the pulp mixture against the wire to eliminate water within the mixture and to form the desired paper thickness. The material then proceeds to a drying section where it travels across numerous cylindrical dryers that are heated with steam. In the final section of the paper machine, long sections of paperboard are rolled up into parent rolls and are removed from the machine. The parent roll is further processed by FIPC's customers to make various types of paperboard containers.

Sometimes customers require additional processes to be performed on parent rolls. For example, food processors often require widths of 18 inches, rather than the standard width of a reel (approximately 12 feet). Thus, reels are loaded onto a rewinder slitter to produce eight reels 18 inches wide from one reel 12 feet wide. For convenience, Forest Industries had always combined labor and machine costs of the rewinder slitter with those of the paper machine for allocation purposes. Thus, all grades of paperboard shared in the costs of slitting even though most grades were not slit. Additionally, only a minor setup fee was charged to customers requesting slit parent rolls, as this was viewed as incidental customer service. Engineering studies suggest the slitting may be more expensive than previously thought.

Forest Industries traditionally applied overhead to production as a function of materials costs: thicker materials required more machine time to process as they demanded slower machine speeds and more energy to dry. Thus, unit-level drivers made sense for applying certain types of overhead to products. However, other important costs were incurred without respect to volume. For example, grade changes induce instabilities into the process that result in scrap until the process resumes stability. On average, production engineers estimate that approximately one-half reel is lost to scrap each time a grade change is made. Just as discrete-part manufacturers incur machine setup costs between production runs of two different products, scrap produced following grade changes is a predictable cost of production.

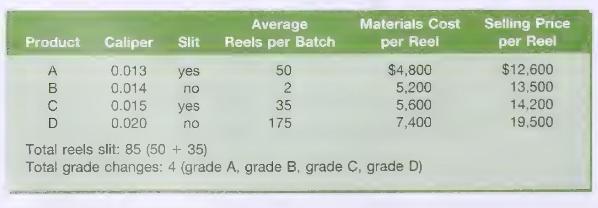

A sample representing significant categories of grades is presented in Exhibit A. The sample contains thin paperboard grades (caliper 0.013 ) as well as heavier grades (caliper 0.02). In addition, Exhibit A identifies whether a grade typically is slit. The sample is representative of the variation in batch quantities. As shown below, some grades are produced in small quantities, while the market demands significantly more production in other grades. Materials cost per reel includes pulp and chemical costs, while the selling price reflects recent market prices.

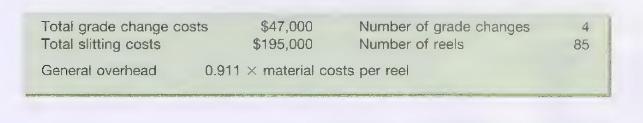

In the past, Forest Industries' accountants estimated that manufacturing overhead, including labor, energy, and depreciation on capital equipment, approximated \(105 \%\) of material costs. Historically, product costs at Forest Industries were calculated by multiplying the overhead rate by direct material costs. However, brand managers had begun to suspect that some grades were subsidizing others with respect to costs. Two significant activities, grade changes and slitting, were identified to help reduce cross-subsidy and provide more accurate cost estimates. Exhibit B summarizes information obtained from the activity-based costing study.

The capital-intensive structure of a paper company coupled with the cyclical nature of the industry makes accurate cost information an important strategic tool. Though current demand exceeds existing capacity, managers at Forest Industries know that a downturn is inevitable. They understood different pricing and production mix strategies are necessary when the economic environment changes. Gaining an understanding of the costs associated with grade changes and slitting is a first step that will enable managers to more effectively manage their business in good times and in bad.

\section*{Required}

A. Compute the volume-based, traditional cost per reel for grades A-D identified in Exhibit A, B. What is the total cost for Forest Industries to conduct a grade change?

C. What is the grade change cost for each reel? (Hint: The reel cost will differ because batch sizes are not equal.)

D. What is the cost to slit a reel of paperboard? (Hint: How many reels are slit? Do all reels require slitting services?)

E. Using the information in Exhibit B, calculate the amount of general overhead to be applied to each reel of paper.

F. Determine the activity-based cost for grades A-D.

G. Prepare a chart that illustrates the percentage change in costs between the volumebased system and the strategic activity-based cost system (ABC cost - volume-based system cost) \(\div\) volume-based system cost.

H. As a consultant to Forest Industries, what action would you recommend?

Step by Step Answer:

Managerial Accounting Information For Decisions

ISBN: 9780324222432

4th Edition

Authors: Thomas L. Albright , Robert W. Ingram, John S. Hill