Stellhorn Snacks produces high-quality potato chips. The manufacturing process is highly automated, yet requires labor to handle,

Question:

Stellhorn Snacks produces high-quality potato chips. The manufacturing process is highly automated, yet requires labor to handle, inspect, and sort potatoes and chips. Stellhorn has accumulated product costs using process costing in the past and is considering adopting a standard cost accounting system.

At the beginning of the manufacturing process, potatoes are scrubbed and cleaned in an automatic washer. The potatoes then are placed automatically on a conveyor that feeds them into an automatic peeling machine. After the potatoes are peeled, they are inspected manually to remove blemishes and to cut out eyes. After inspection, they are placed on another conveyor that feeds them into an automatic slicing machine. The slicer feeds the chips into vats, which are loaded manually into deep fryers and monitored closely by production personnel. After cooking, the chips are drained and placed on another conveyor for final inspection and seasoning. At this point, unacceptable chips are sorted from good production, and the good chips are fed into an automatic bagger. The bagging process is highly automated, requiring one operator to load the empty bags for filling, and another person to remove the bags once they have been sealed and place them in cartons for final shipment.

Stellhorn expects to purchase potatoes of acceptable grade and quality for \(\$ 0.08\) a pound. Based on historical records, Stellhorn has determined that it can produce 152 ounces of chips for every 10 pounds of potatoes placed into production. Each bag of chips produced contains 19 ounces of chips. Other direct materials include bags and boxes, which amount to \(\$ 0.14\) per bag of chips. All other materials, such as oil and seasoning, are treated as indirect costs.

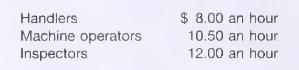

Stellhorn operates under a union contract and has three distinct classes, or categories, of employees. The established classes and the agreed-upon hourly rates for direct laborers are as follows:

For the coming year, Stellhorn expects to produce six million bags of chips. For this level of production, the company has determined that it will require 10,800 hours of handler time, 12,000 hours of machine operator time, and 14,800 hours of inspection.

Variable overhead is applied on the basis of direct labor hours and historically has averaged \(110 \%\) of labor dollars. The budgeted fixed overhead for the coming year is \(\$ 1,350,000\), and also is applied based on direct labor hours.

\section*{Required}

A. Discuss the benefits Stellhorn would realize by adopting a standard cost accounting system.

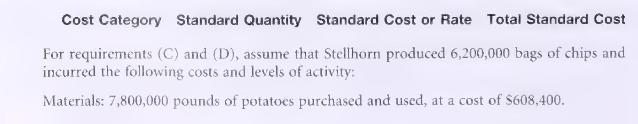

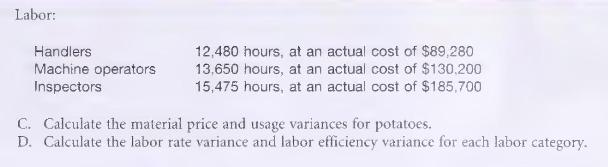

B. Using the following format, develop a standard cost sheet for material, labor, and overhead for each bag of potato chips.

Step by Step Answer:

Managerial Accounting Information For Decisions

ISBN: 9780324222432

4th Edition

Authors: Thomas L. Albright , Robert W. Ingram, John S. Hill