And do you have the answer to Problem 6, Pete? asked Professor Grasso. Yes sir, I have

Question:

€œYes sir, I have the answer according to the textbook, but I€™m not sure I get it,€ replied Pete.

€œYou don€™t understand how to get the solution?€

€œOh, I understand the numbers, but I don€™t know what they€™re good for. Where I work, nobody ever €˜sequences€™ anything. You don€™t have time to calculate things like slack and critical ratio. You do what€™s next in line or on top of the stack, unless you see a red tag on something that needs to be rushed through. Or maybe you run what€™s most like what you€™ve just finished working on so the machine doesn€™t have to be changed. Or you run what can get done the fastest because when you produce more you get paid more.€

€œPete, it sounds to me like you are using sequencing rules€”FCFS, highest priority, minimum setup, and SPT.€

Pete hesitated. €œMaybe you€™re right, but there€™s still something that bothers me. If you€™re going to go to all the trouble to rearrange a stack of jobs, you€™d want more information than what we€™re working with.€

€œWhat do you mean?€

€œI mean, there€™s no use rushing a job at one station to let it sit and wait at the next. It€™s like those maniacs who break their neck to pass you on the road, but they never get anywhere. A few minutes later you€™re right behind them at a stoplight.€

€œI see.€

€œYou need some way of looking at the entire job, where it€™s going next, what resources it€™s going to use, if it has to be assembled with something else, things like that.€

€œYou€™ve got a point, Pete. Why don€™t you give us a €˜real€™ example we can work with? You talk, I€™ll write it on the board.€

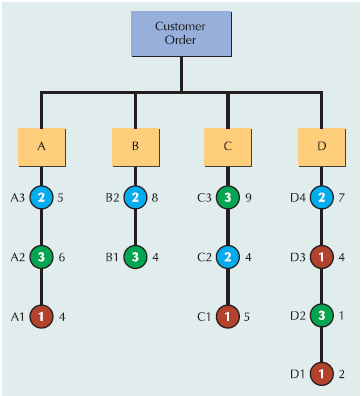

Pete talked for about 10 more minutes, and when he was finished, Professor Grasso had the following diagram on the board.

€œOkay, class, let€™s take this home and work on it. A, B, C, and D are products that comprise a customer€™s order. They must all be completed before the order can be shipped. The circles represent operations that must be performed to make each product. We€™ve labeled them A1 for the first operation of product A, A2 for the second operation, and so on. The numbers inside the circles are the machines, that are used to perform each operation. We have only three machines 1, 2, and 3. Your job is to decide the sequence in which the products should be processed on each machine. There is no setup time between processes, no inventory on hand, and nothing on order. Assume the customer has ordered 50 units of each product. We€™ll use a process batch of 100 units and a transfer batch of one. Make a Gantt chart for each machine to show us how quickly you can ship the customer€™s order. Earliest shipment gets 5 extra points on the final exam.€

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Related Book For

Operations and Supply Chain Management

ISBN: 978-1119444404

9th edition

Authors: Roberta S. Russell, Bernard W. Taylor

Question Posted: